- Joined

- Feb 10, 2016

- Messages

- 34

- Reaction score

- 0

- Location

- Lovingston, Virginia

- My Car

- 1971 Mach 1 M-code

I am helping Cobra2572 rebuild his 71 Mach 1 351C 4V and want some advice on the stock valve train/heads.

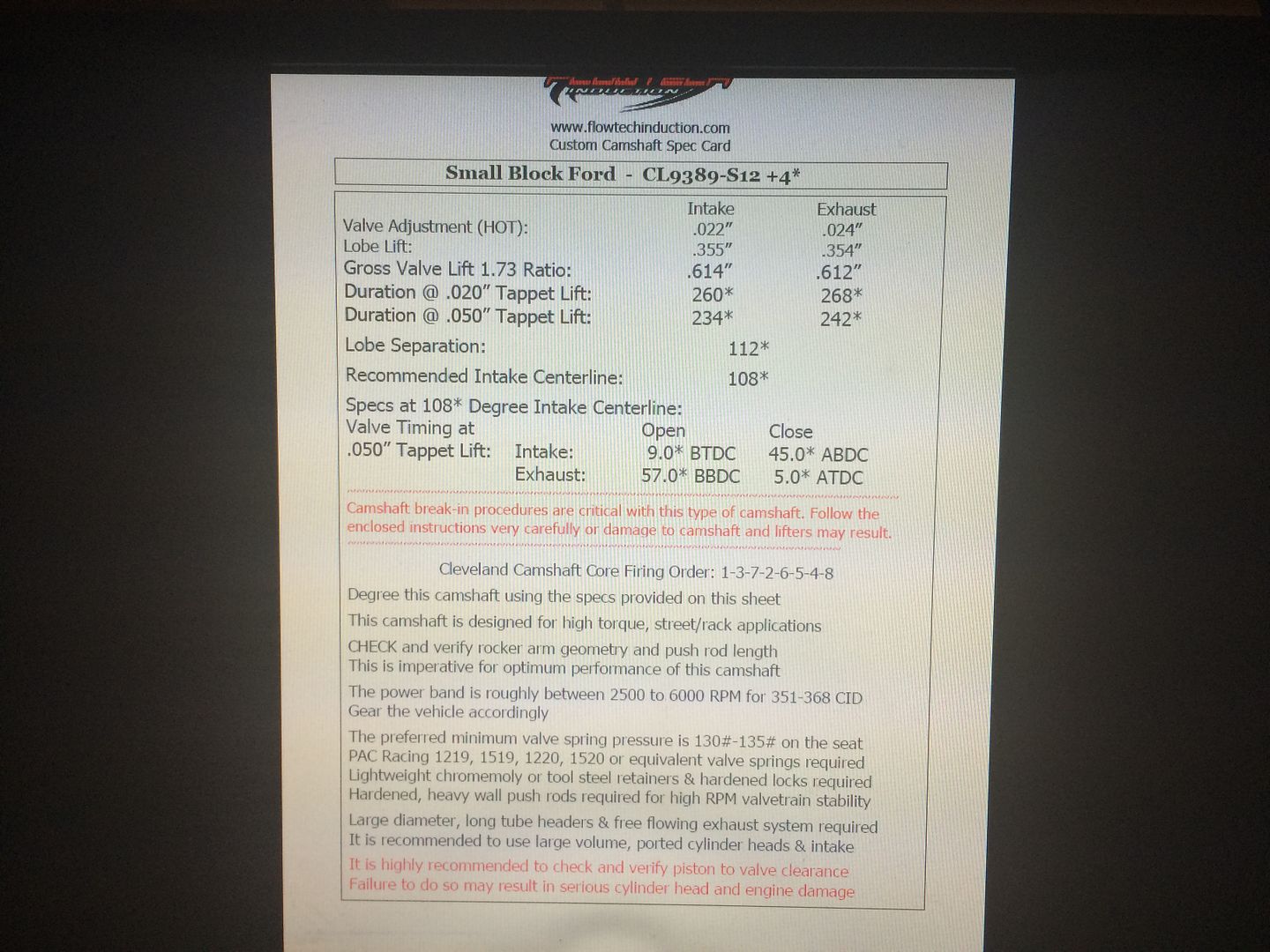

I am helping Cobra2572 rebuild his 71 Mach 1 351C 4V and want some advice on the stock valve train/heads.The block is at the machine shop getting bored .030 over and the engine kit has been purchased. The pistons are Sealed Power L2379F30 forged pistons that show 10.76:1 compression ratio with 58.6 cc combustion Chamber heads. I believe the closed chamber heads on the 71 4V are actually 63 cc's, so the compression will be slightly reduced. The Camshaft is an Erson cam part number E220221 hydraulic flat tappet unit. Advertised lift is .536/.536 and advertised duration is 310/310. Lobe separation angle is 114 degrees. The @ .050 numbers are .310/.310 lift and 226/226 duration. Intake centerline is listed on the cam card at 106 degrees.

I am of the opinion that the valves need to be replaced due to the weak nature of the multiple groove locks and 2 piece valves. When we tore down the engine, the intake valve in cylinder 2 was broken. In addition to new valves, I believe hardened exhaust seats should be installed.

Now the questions...

Are the stock springs good enough for the camshaft that we have or should they be replaced? The specs on the cam card recommend springs with 110 lb seat pressure and 250-280 lb open pressure.

Should all of the valves be replaced or just the broken or damaged ones? Heads have not been torn down or inspected yet.

Should hardened seats be installed?

This will be a street only vehicle and is a 4 speed car. My friend Cobra2572 (Dave) wants a close to stock rebuild with a slightly hotter camshaft which is the reason for the camshaft that was purchased.

Since I have no experience with 351C Engines I would like some feedback on this. My real experience is 383 and 440 Mopars.