- Joined

- Jun 15, 2011

- Messages

- 1,989

- Reaction score

- 1

- Location

- Wisconsin

- My Car

- 73 Mach 1 Mustang (project)

93 Dodge Shadow (daily)

86 Buick Regal (2nd project)

Hey fellas (and gals), its been far too long since I've posted. I've finally started working on my mustang again after 2 or 3 years of not doing anything to it. So, I figured that doing the cam and head swap should be a nice little project to get me motivated to work on it more... About that, I took the intake off and noticed a nice gas aroma from the oil. After draining the oil I found out that gas had been getting into the oil along with some water and some shiny metal. I had been contemplating pulling the motor but now I guess it made that decision easier for me. I should have the motor out and torn down this weekend.

I'm looking for around 400(ish)HP so here's my plan for the motor:

-Ported and polished 2V open chamber heads (they're not ideal but should work)

-Comp Cams XE262H 218/224 @ .050 lift http://www.compcams.com/Company/CC/cam-s...d=847&sb=2

-Harland Sharp 1.73 ratio roller rockers

-Edelbrock Performer intake

-Holley street avenger 770cfm carb (I know this is kind of large for my application but I got it cheap so I'll try it out)

-undecided on pistons (Forged vs Hyper)

-undecided on the ignition system

With all that being said I have a couple of questions for you guys about the build up of my 351C:

Is there anything I should look at upgrading while I have the motor out to get rebuilt?

Do you have any suggestions for what pistons and ignition system to run?

Is it worth going with ARP head studs, main bearing studs and rod bolts?

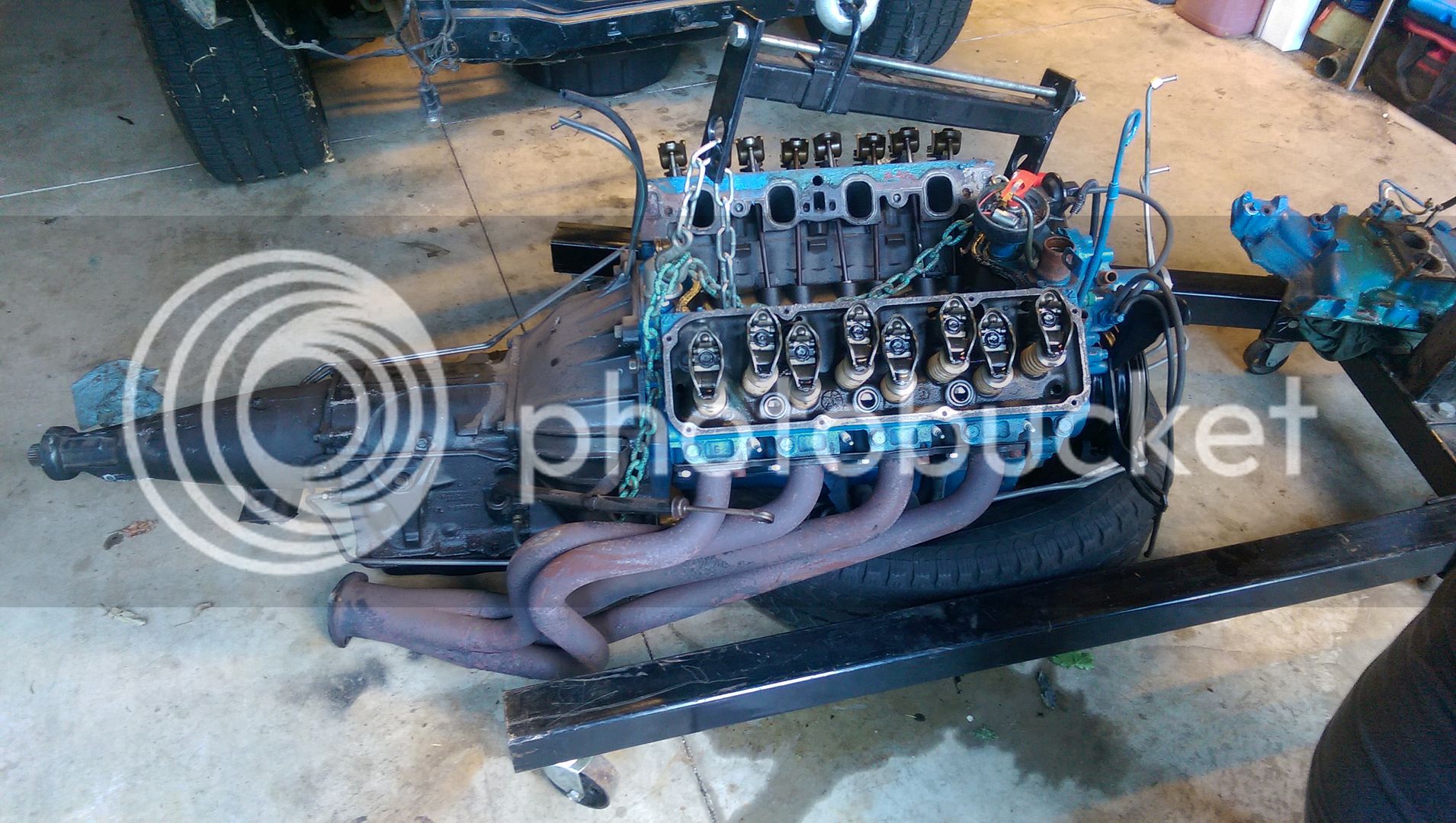

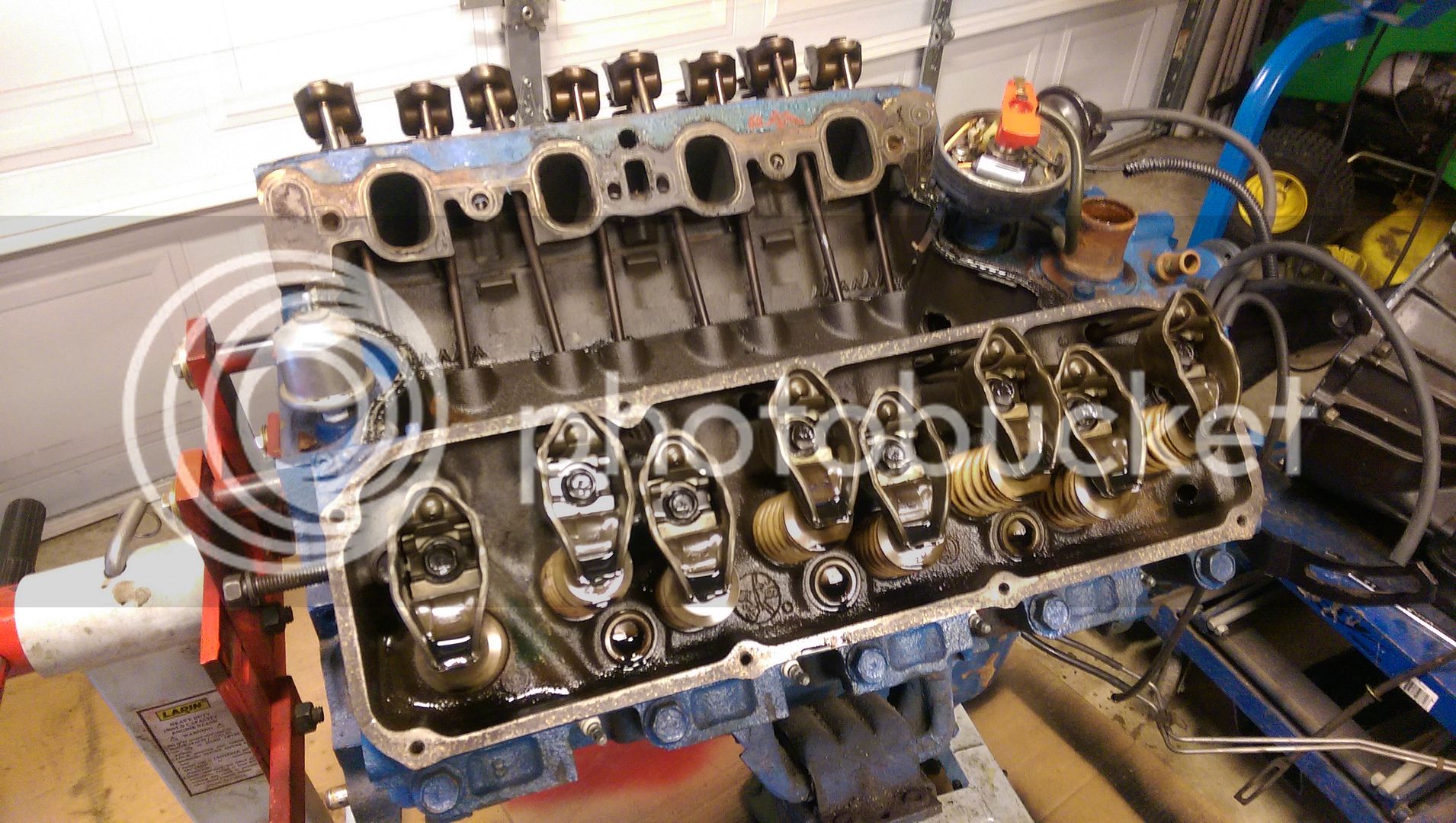

motor in its current state:

Sorry, for the long post and thanks for looking.

I'm looking for around 400(ish)HP so here's my plan for the motor:

-Ported and polished 2V open chamber heads (they're not ideal but should work)

-Comp Cams XE262H 218/224 @ .050 lift http://www.compcams.com/Company/CC/cam-s...d=847&sb=2

-Harland Sharp 1.73 ratio roller rockers

-Edelbrock Performer intake

-Holley street avenger 770cfm carb (I know this is kind of large for my application but I got it cheap so I'll try it out)

-undecided on pistons (Forged vs Hyper)

-undecided on the ignition system

With all that being said I have a couple of questions for you guys about the build up of my 351C:

Is there anything I should look at upgrading while I have the motor out to get rebuilt?

Do you have any suggestions for what pistons and ignition system to run?

Is it worth going with ARP head studs, main bearing studs and rod bolts?

motor in its current state:

Sorry, for the long post and thanks for looking.