- Joined

- Mar 30, 2017

- Messages

- 2,333

- Reaction score

- 815

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

As my Holley 650 double pumper decided to leak bad one more time.

I just made the jump and ordered the Holley Sniper, master kit #550-511K, as I've

seen not much Holley parts keep their shiny finish for long. I went for black ceramic.

I've ordererd a separate bung to weld it for durable installation vs the clamp thingy they provide in the kit.

As usual, no support for ford kickdown, so ordered a Lokar kickdown kit for the fmx that should fit just fine and use the

non ford provided stud on the unit.

I've red like 10 times the specs, watched a bunch of EFI installs vids. I think I can get that baby up&running

without major probs. Too late for second thoughts anyway!

However, since it will be shipped end of june (aaaaaarggggghh, means mid july over here) and as none of the videos

I've seen covers a 71-73. I have a few questions unanswered... and would like prep some stuffs if possible before it arrives.

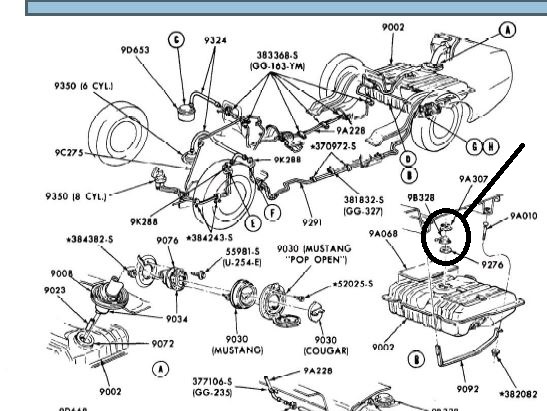

Like, what would be the best route for the fuel lines? Best location for fuel pump? Ideal location for the sensor...? Tips?

If anyone already installed one of these please (or another carb replacement EFI) come forward and tell me all about it so I can endure this looong wait

I just made the jump and ordered the Holley Sniper, master kit #550-511K, as I've

seen not much Holley parts keep their shiny finish for long. I went for black ceramic.

I've ordererd a separate bung to weld it for durable installation vs the clamp thingy they provide in the kit.

As usual, no support for ford kickdown, so ordered a Lokar kickdown kit for the fmx that should fit just fine and use the

non ford provided stud on the unit.

I've red like 10 times the specs, watched a bunch of EFI installs vids. I think I can get that baby up&running

without major probs. Too late for second thoughts anyway!

However, since it will be shipped end of june (aaaaaarggggghh, means mid july over here) and as none of the videos

I've seen covers a 71-73. I have a few questions unanswered... and would like prep some stuffs if possible before it arrives.

Like, what would be the best route for the fuel lines? Best location for fuel pump? Ideal location for the sensor...? Tips?

If anyone already installed one of these please (or another carb replacement EFI) come forward and tell me all about it so I can endure this looong wait