rotorr22

Well-known member

- Joined

- Jan 4, 2018

- Messages

- 56

- Reaction score

- 1

- Location

- NE Ohio

- My Car

- No 71/73 yet. Previously owned a 71 Boss 351 and a 73 Mach 1

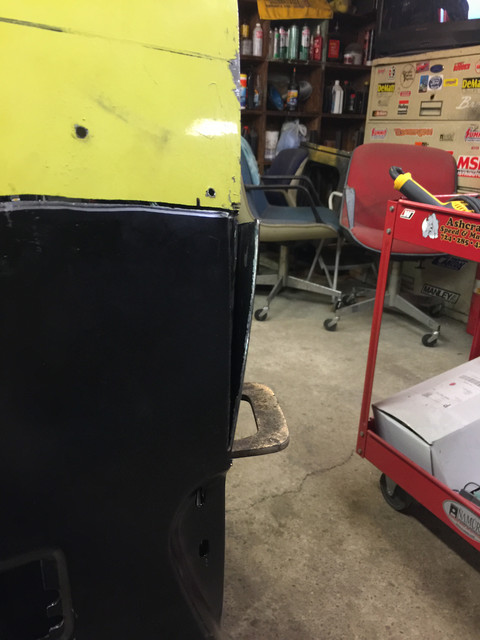

Has anyone purchased and installed this quarter panel skin? If so, how is the fit?

https://www.cjponyparts.com/quarter-panel-skin-fastback-1971-1973/p/QPS7-V/

https://www.cjponyparts.com/quarter-panel-skin-fastback-1971-1973/p/QPS7-V/