- Joined

- Mar 30, 2017

- Messages

- 2,337

- Reaction score

- 820

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

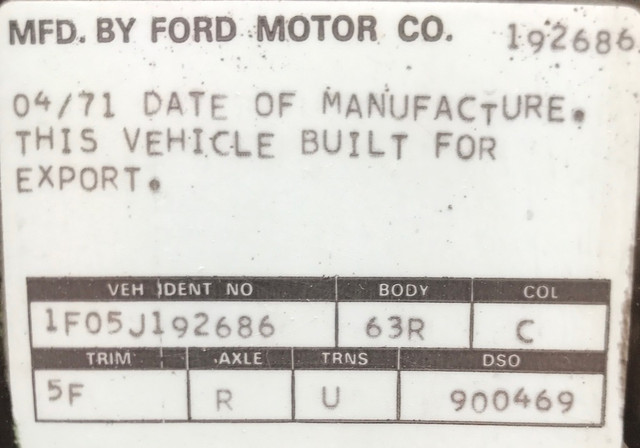

I thought that day will never arrive... I've decided to start on the 71!

I got this 429CJ matching numbers back in 2000. till mid 90's it ran in Paris and then in south west of France very very strong (very very thirsty too).

The PO, a good friend of mine, placed a new Lunatti cam in it, and within few weeks, engine died and never started again.

My friend, in middle of divorce and other stuffs, had no time and brought it to a local 'specialist'. This brave man took his time, removed/opened the engine, the trans and the dashboard for unknown reasons, and with parts all over the place he decided it was time for him to retire and shut down his shop business. Not touching the car further or put it back together.

The car stayed in this garage for 2 years under this guy heavy tortures. My friend tired of all the extra stress in his life at the time, called me and said.

You want the car? Come get it or it goes to the crusher...

18 hours later, I arrived at the garage with a trailer. Went to this garage, all tools, parts where all over like if someone was in a lunch break. I've collected all the parts I could find laying around, each and every bolt, washers, brackets... Then went to another shop where the engine was for check. They found out a lobe on the new cam went round. So after collecting all engine parts over there, put all in the car and went back home.

As the 73 was under surgery in my garage at the time, it went into a friend's barn till I would come to it. The engine block however went straight to a machine shop I know, where lower engine was checked/put back together. new pistons/rings etc.. and stayed in my garage since then.

20 years passed.

This is what 20 years of dutch dust looks like.

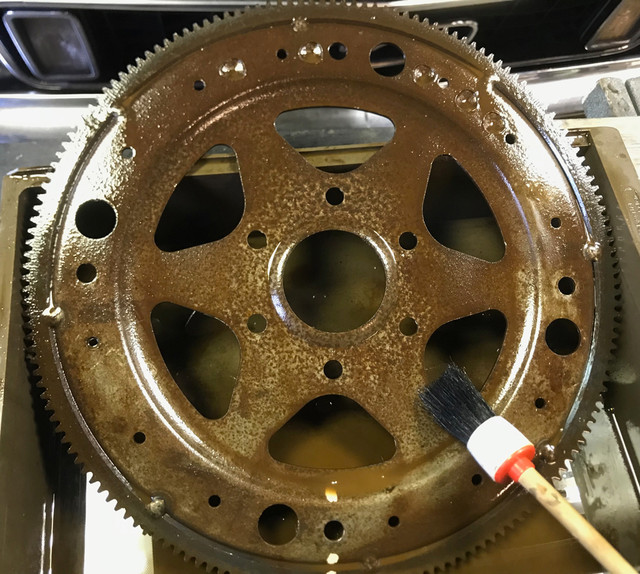

Last week I went thru all engine parts I got, spited in my hands and so became the 71 next on my todo

First goal: put the engine together, so I can free some space in the garage.

While busy looking at what I can (re)use, and what I need, I started with the first candidate: the intake.

The heads kept in oil will go to the machining shop for a well deserved bath and valves/surface job.

I have the original one but being as heavy as my wife's mini, I will not use it and use the hoffy my friend placed on the engine.

As it gave a noticeable boost to the engine back then above the original, all it needs is to be refreshed a bit.

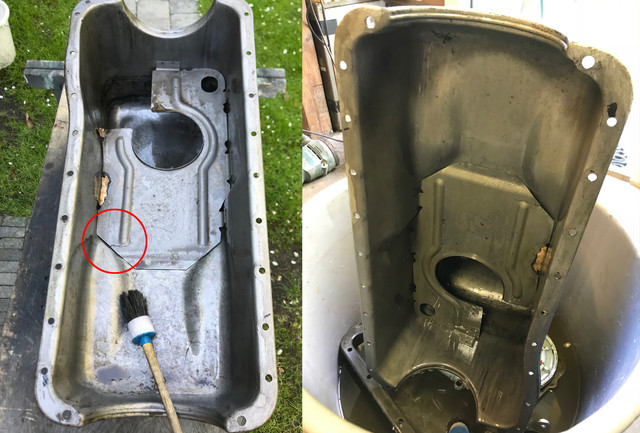

Here the lower engine in its time capsule and the dirty intake.

After one hour labor and no real changes, I decided use big gun.

After a high pressure massage, the aluminium started look more aluminium.

Tons of detergent, brushes, belgom, swet and tears later. I got that baby better than new

I still need improve here and there but it starts looking like an intake!

more to come...

I got this 429CJ matching numbers back in 2000. till mid 90's it ran in Paris and then in south west of France very very strong (very very thirsty too).

The PO, a good friend of mine, placed a new Lunatti cam in it, and within few weeks, engine died and never started again.

My friend, in middle of divorce and other stuffs, had no time and brought it to a local 'specialist'. This brave man took his time, removed/opened the engine, the trans and the dashboard for unknown reasons, and with parts all over the place he decided it was time for him to retire and shut down his shop business. Not touching the car further or put it back together.

The car stayed in this garage for 2 years under this guy heavy tortures. My friend tired of all the extra stress in his life at the time, called me and said.

You want the car? Come get it or it goes to the crusher...

18 hours later, I arrived at the garage with a trailer. Went to this garage, all tools, parts where all over like if someone was in a lunch break. I've collected all the parts I could find laying around, each and every bolt, washers, brackets... Then went to another shop where the engine was for check. They found out a lobe on the new cam went round. So after collecting all engine parts over there, put all in the car and went back home.

As the 73 was under surgery in my garage at the time, it went into a friend's barn till I would come to it. The engine block however went straight to a machine shop I know, where lower engine was checked/put back together. new pistons/rings etc.. and stayed in my garage since then.

20 years passed.

This is what 20 years of dutch dust looks like.

Last week I went thru all engine parts I got, spited in my hands and so became the 71 next on my todo

First goal: put the engine together, so I can free some space in the garage.

While busy looking at what I can (re)use, and what I need, I started with the first candidate: the intake.

The heads kept in oil will go to the machining shop for a well deserved bath and valves/surface job.

I have the original one but being as heavy as my wife's mini, I will not use it and use the hoffy my friend placed on the engine.

As it gave a noticeable boost to the engine back then above the original, all it needs is to be refreshed a bit.

Here the lower engine in its time capsule and the dirty intake.

After one hour labor and no real changes, I decided use big gun.

After a high pressure massage, the aluminium started look more aluminium.

Tons of detergent, brushes, belgom, swet and tears later. I got that baby better than new

I still need improve here and there but it starts looking like an intake!

more to come...

Last edited by a moderator: