- Joined

- Nov 7, 2013

- Messages

- 1,594

- Reaction score

- 286

- Location

- Amsterdam, The Netherlands

- My Car

- 1973 Mustang Grande 351C 2V, built on the very last production day (July 6, 1973) for Grande's.

Well, today marks the start of something scary; I’m taking my 73 Grandé apart to make it better.

The goals:

1) Improved reliability

2) Driving without checking the weather forecast

3) Increased power

4) Better looks (back to original color amongst other things)

I have many ideas, but you’ll have to wait and see

This was the car in its glory days:

Today I started by removing the fuel tank. I don’t want it near me when I’m going to weld in a new taillight panel...

The inside seems totally rust free so I’m keeping it to restore.

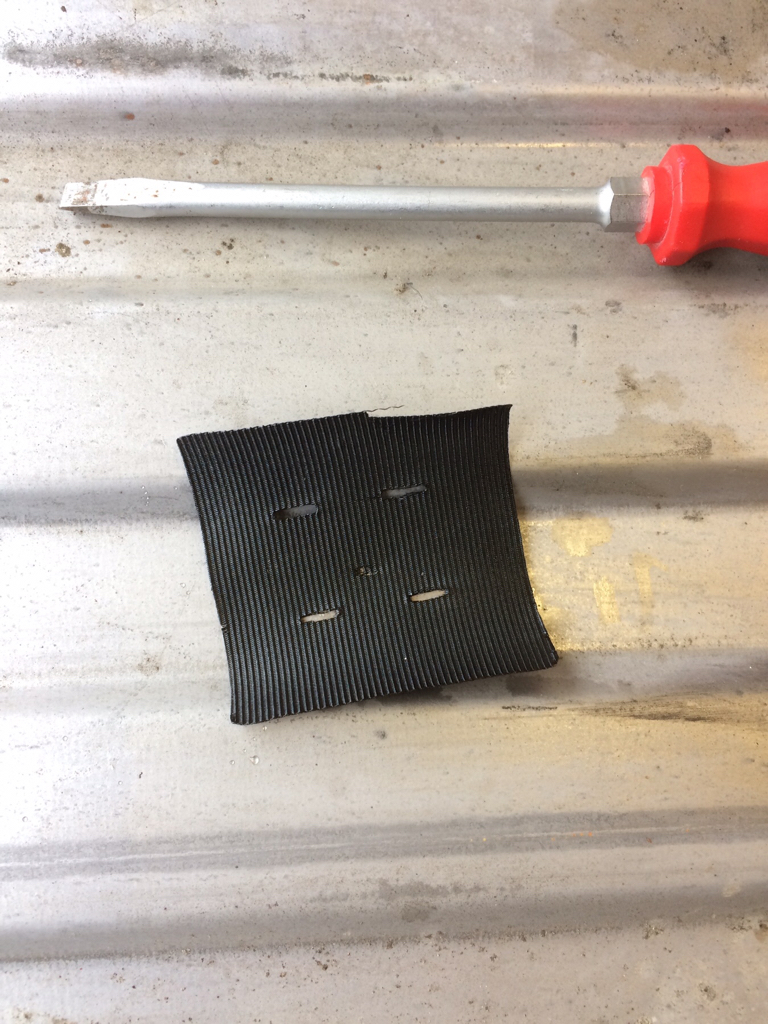

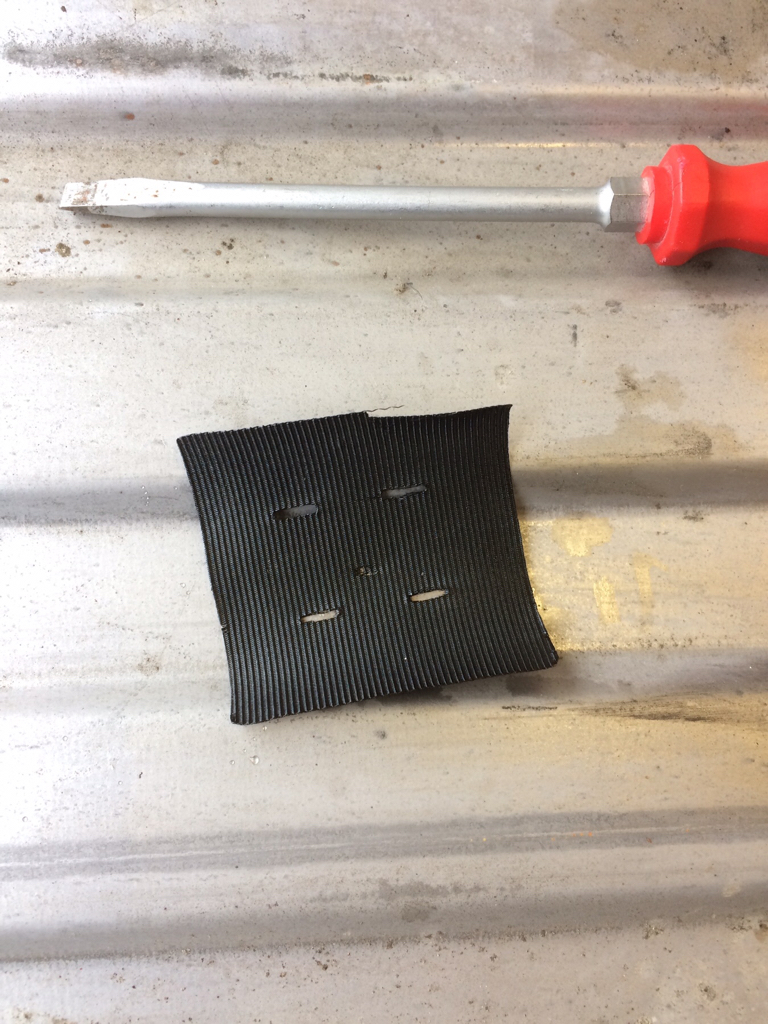

I did find this on the inside, what is it?

And I believe this should have been filled with a foam pad?

More fun tomorrow

PS: the project name is what Fabrice called me after we’d discussed my plans. I think it’s funny

The goals:

1) Improved reliability

2) Driving without checking the weather forecast

3) Increased power

4) Better looks (back to original color amongst other things)

I have many ideas, but you’ll have to wait and see

This was the car in its glory days:

Today I started by removing the fuel tank. I don’t want it near me when I’m going to weld in a new taillight panel...

The inside seems totally rust free so I’m keeping it to restore.

I did find this on the inside, what is it?

And I believe this should have been filled with a foam pad?

More fun tomorrow

PS: the project name is what Fabrice called me after we’d discussed my plans. I think it’s funny

Last edited: