- Joined

- Feb 28, 2011

- Messages

- 257

- Reaction score

- 5

- Location

- California

- My Car

- 1971 Mach 1

2000 F250-SD

2001 H-D FLTR

2004 GMC Denali

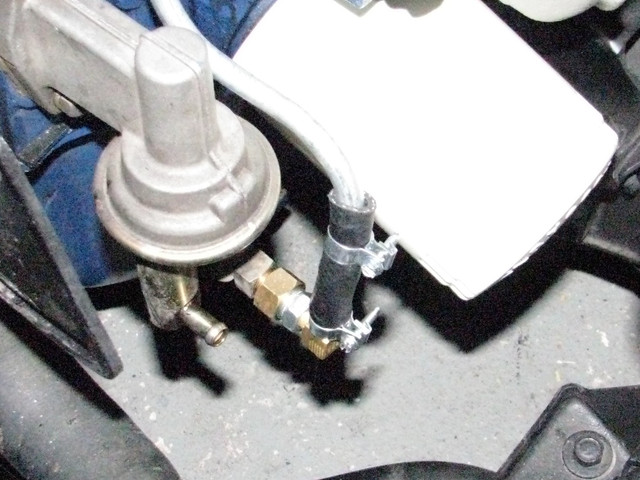

I have a 351 Cleveland that was originally a 2v motor, and in an air conditioned 71' Mach 1

. I have had the motor rebuilt and added an Edelbrock performer rpm air gap manifold and a Holly Avenger carburetor. The car no longer has air conditioning. It appears to me that the original fuel line from the fuel pump is not going to work.

Have any of you had this issue? If so, what fuel line did you use to replace the original?

Thanks in advance.

. I have had the motor rebuilt and added an Edelbrock performer rpm air gap manifold and a Holly Avenger carburetor. The car no longer has air conditioning. It appears to me that the original fuel line from the fuel pump is not going to work.

Have any of you had this issue? If so, what fuel line did you use to replace the original?

Thanks in advance.