You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sooty day’s...

- Thread starter 7173Vert

- Start date

Help Support 7173Mustangs.com:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 3, 2016

- Messages

- 642

- Reaction score

- 97

- Location

- delaware

- My Car

- 1973 convertible with 351C and C6 trans

looking at the floor, i'd say u had condensation in the exh pipe and when u fired it up it shot out.. should not be a problem.. self cleaning.

do only drive short distance? this can build up soot, or is engine smoking this also will soot up.

do only drive short distance? this can build up soot, or is engine smoking this also will soot up.

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

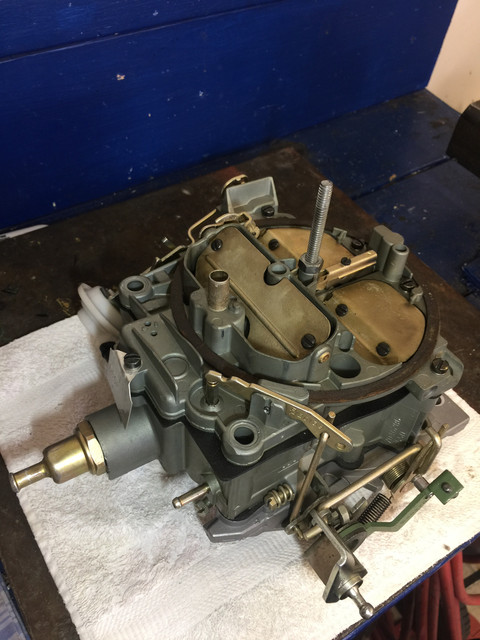

Definitely some condensation for sure. My bad, the car is not run often and even less on the road. But, there is another issue for sure. After writing this I went out and looked at the carb. Both idle mixture screws were turned in all the way, seated. I noticed fuel coming out the top of the accelerator pump, puddling when the car is running. The exhaust is burning my eyes... You can smell the unburned fuel. I think I have a flooding issue. What pisses me off is I paid a guy to set the carb up over a year ago. Who sends a car out the door with both idle mixture screws Seated? The car always starts and runs, choke works; but I could always smelll unburned fuel and see the Smokey exhaust. May have to pulll the carb. And check the float and needle valve.looking at the floor, i'd say u had condensation in the exh pipe and when u fired it up it shot out.. should not be a problem.. self cleaning.

do only drive short distance? this can build up soot, or is engine smoking this also will soot up.

- Joined

- Sep 30, 2010

- Messages

- 6,166

- Reaction score

- 1,131

- Location

- Mustang, OK.

- My Car

- 1972 Mach 1 Q code

2007 GT

1969 Cougar Eliminator B302

CSX 7000 Shelby Cobra FIA

2020 Edge ST

2002 F250 V10

The low life you paid is at best a thief, and that is to insult to thieves worldwide. This may sound a bit off but, ask the local GM guys who is good at 60s-70s Rochesters. Personal experience references being the most valuable. Rochesters can be as problematic as 4300Ds but, there are know fixes for the GM stuff which applies to your carb as well. The biggest difference is the fuel inlet. I'd also change the oil and filter, excessive fuel contamination can do bad things to an engine. I hope you get it sorted out without too much drama and cost. Chuck

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

So, I decided to take the carb off and check the float and needle seat set up as this would be the main reason for excessive fuel getting into the engine. I know the choke is working correctly, the car runs and wants to run.. I found out that the idle mix screws had been seated by the mechanic who I trusted to set the carb up... Shows you can’t trust anyone these day’s... At the end of the day, if you are going to own one of these classics, you have to learn to do the work yourself. I can do a lot, but the carb set up has always been a challenge for me personally. Well, that changes moving forward. I have yet to confirm the set timing, but decided to wait until I confirm the internal of the carb itself...

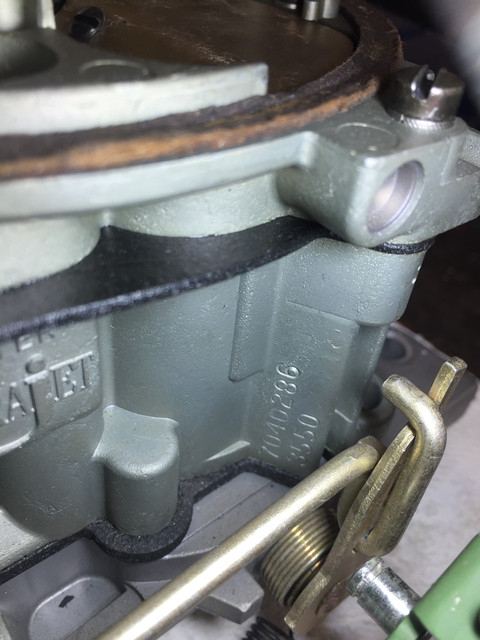

The second pic confirms this is the correct date coded carb for my car, based on my car’s build date. Pt. #7040286 is the correct part # for a ‘71 429cj with the C-6 trans and factory A/C. $1500 US $$$ paid for this piece (restored), simply because I wanted the date code correct piece... The date code on this carb is located just below the Pt. Number. It reads 3550. This equates to December 21, 1970, which is within general acceptable timelines for my car’s build date.

Now, I will take the top housing off to see what is happening here. Stay tuned.

Last edited by a moderator:

- Joined

- Jan 7, 2015

- Messages

- 8,032

- Reaction score

- 526

- Location

- Western North Carolina

- My Car

- Multiple Mustangs!

For sure sounds like a float or float setting issue. The 4300 had a special float check gauge that could check the carburetor on the engine without removing from the vent hole.

I know nothing about a Rochester for sure. Be very cautious when you take the 4300 apart there are small ball bearing and also a needle seat that will fall out when you turn the carb over.

Do a google search there is a carb guy that has lots of informative video posted. Can't remember his name, lol.

I know nothing about a Rochester for sure. Be very cautious when you take the 4300 apart there are small ball bearing and also a needle seat that will fall out when you turn the carb over.

Do a google search there is a carb guy that has lots of informative video posted. Can't remember his name, lol.

- Joined

- Jan 1, 2012

- Messages

- 8,357

- Reaction score

- 1,200

- Location

- Eugene, OR

- My Car

- 1971 Mustang Sportroof M code

Do you have a manual for Quadrajets? Mike's Carburetor Parts has a lot of free manuals for download (including Quadrajet), as well as hard to find parts, like throttle shaft bushings, and other information.

https://www.carburetor-parts.com/Free-Carburetor-Manuals_ep_274.html

https://www.carburetor-parts.com/Free-Carburetor-Manuals_ep_274.html

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

C

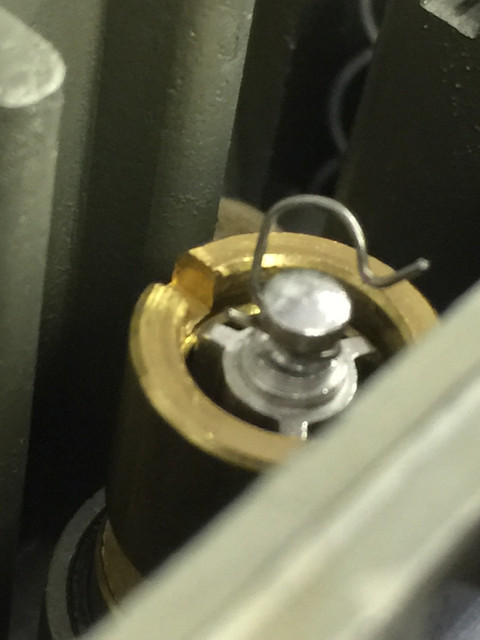

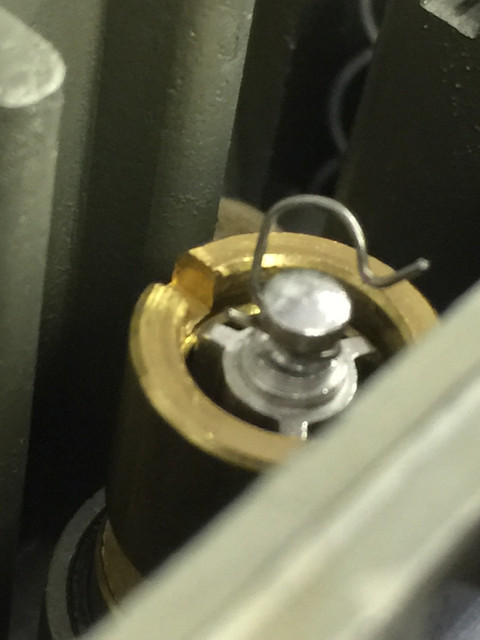

Making progress... but maybe not. as you can see, the carb is spotless inside. I pulled the fuel inlet needle valve, perfect shape. Pulled the needle valve housing to bet a good look to ensure no obstructions, again, clear as a blue summer sky...

While I have the carb off, I confirmed that the plugs underneath were 2 part epoxied as this can cause a fuel leak. Also confirmed the metal shim is in place on the needle housing before screwing back into the body. Again, this looks good.

The float seems to sit ok, haven’t checked specs yet, but it seems okI will confirm the factory measurement before putting the carbback together. Time to do more research...

Making progress... but maybe not. as you can see, the carb is spotless inside. I pulled the fuel inlet needle valve, perfect shape. Pulled the needle valve housing to bet a good look to ensure no obstructions, again, clear as a blue summer sky...

While I have the carb off, I confirmed that the plugs underneath were 2 part epoxied as this can cause a fuel leak. Also confirmed the metal shim is in place on the needle housing before screwing back into the body. Again, this looks good.

The float seems to sit ok, haven’t checked specs yet, but it seems okI will confirm the factory measurement before putting the carbback together. Time to do more research...

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

Yes Don. Haven’t looked at yet. This will be my next step said:Do you have a manual for Quadrajets? Mike's Carburetor Parts has a lot of free manuals for download (including Quadrajet), as well as hard to find parts, like throttle shaft bushings, and other information.

https://www.carburetor-parts.com/Free-Carburetor-Manuals_ep_274.html

Last edited by a moderator:

- Joined

- Apr 19, 2011

- Messages

- 1,455

- Reaction score

- 79

- Location

- Buffalo, NY

- My Car

- 1969 Convertible Restomod enhanced.

former owner (25 yrs) of 1973 Convertible, 351c, A/C, RA

Hi Ken: looks like you dove right into the carb issue. Old school carb tuning technique I've used since the 60's as an initial setup. Once you have things re-assembled, initial tuning at warm idle would be to hook up your engine analyzer to monitor rpm and dwell and hook up vacuum gauge. 1 -1/2 turns out the on mixture screws. Using 1/8 - 1/4 turns on each mixture screw (let it run for 15-30 seconds before another adjustment) set it to the highest vacuum you can achieve.

Once you have set it as best you can using this technique, see if you can find someone who can plug emissions analyzer into exhaust pipe to check readings. Obviously the folks who do this on a dyno can do the best job since they can set it up with loaded conditions. Problem is finding someone who understands Q-jets with dyno.....

Once you have set it as best you can using this technique, see if you can find someone who can plug emissions analyzer into exhaust pipe to check readings. Obviously the folks who do this on a dyno can do the best job since they can set it up with loaded conditions. Problem is finding someone who understands Q-jets with dyno.....

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

For sure Bill... I have always started with them around 2 turns out. I was surprised and obviously disappointed to find them completed seated, has been this way for a while now, as I rarely ran the engine the past two year's, always saying to myyself that one day I will take a long look at the issue... I am finding after spending this recent time, reading the manuals, etc, that the Quadrajet is not really a difficult carb to work on. Once i am pretty sure that the internals of the carb are as they should be, I will return the carb to the car and start the process of trying to set it up properly. i am sure the timing is out of whack too, if the idle mixture screws were left like this... I doubt I can find anyone here in Southern Ontario who can both dyno and set up the Quadrajet properly. Everything with dyno's here today is geared towards the newer car's. I will look for vacuum leaks, check the plugs, all that good stuff. I'll let you know how it goes... no visits until this puppy is working as it should :bouncy:Hi Ken: looks like you dove right into the carb issue. Old school carb tuning technique I've used since the 60's as an initial setup. Once you have things re-assembled, initial tuning at warm idle would be to hook up your engine analyzer to monitor rpm and dwell and hook up vacuum gauge. 1 -1/2 turns out the on mixture screws. Using 1/8 - 1/4 turns on each mixture screw (let it run for 15-30 seconds before another adjustment) set it to the highest vacuum you can achieve.

Once you have set it as best you can using this technique, see if you can find someone who can plug emissions analyzer into exhaust pipe to check readings. Obviously the folks who do this on a dyno can do the best job since they can set it up with loaded conditions. Problem is finding someone who understands Q-jets with dyno.....

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

All back together. The good news is I could not locate any definite concerns. I confirmed the float height at 11/32”, no binding, no saturation. I played around with the float needle valve to ensure that it was installed and seating properly and filled the bowl with gasoline to ensure there was no leakage at the needle valve and at the drilled plugs on the bottem end. Turned the idle mixture screws out 2 turns to start... I’ll put her back In and get her runnning, confirm the choke is still good. Once she is warmed up I’ll start checking vacuum, timing, etc to see if I can get her running properly.... I now have confidence that the carb itself does not appear to be my problem moving forward.

Last edited by a moderator:

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

Spent 7 hrs yesterday trying to set the carb, Tune the engine... No luck, yet. Had the carb off and apart again... to recheck the 4 well plugs for leakage. They were fine. Float, bang on. Checked the fuel pressure from the fuel pump, a little over 7 psi... Thought this was a little high, so swapped out the fuel pump and yep, that was 7 psi too. Three hours wasted there ( Fun job on the big block with A/C)... Checked CO readings, almost double to triple what the factory spec’d (Although the pic reads 8, it was more like 10 on average no matter what was tried. Total timing dialed in at 38 degrees (tried a couple different settings). Had the idle mixture screws somewhat helping out... Of course my Pertronix decided to crap out, so back to points... Also found that the coil was beyond infinity... Pisses me off, all these new (coil, Pertronix), supposedly factory spec or improvement parts failing after just a few hours run time... After more research, talking to more knowledgeable GM carb guru’s..., going to try changing (re-calibrate) out the power valve spring, maybe it is coming on during idle... Just too much fuel reaching the engine at idle. I will put new oil and plugs once i get this sorted... :shootself:

Last edited by a moderator:

- Joined

- Jan 1, 2012

- Messages

- 8,357

- Reaction score

- 1,200

- Location

- Eugene, OR

- My Car

- 1971 Mustang Sportroof M code

This is a bit of a long shot, but many years ago a friend had a problem with running rich, hard starting, and gas in the oil. The mechanic couldn't figure it out, so I took a stab at it. Everything looked OK, so filled the fuel bowl and let it set for a while. Sure enough empty fuel bowl and work bench had a puddle on it. Took a while, but I finally found it, a porosity in the casting on the inside edge of the fuel bowl. So, when it would set for a while the fuel would drain into the lowest point and past the rings. Every start-up required refilling the fuel bowl.

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

Not a long shot Don... As you are probably aware, these carbs are notorious for having the fuel bowl empty after sitting for a while. My previous 'J" Code mach had this issue for 15 years... I would add gas to the carb each time before starting, just became second nature... Never did find the problem, but wasn't as aware of the issue as i am today. The last time I had the carb out in this vert, I did fill the bowl with gas both to check the float level and the well plugs. I left it for a few hours and there was no fuel leakage at all. Now, a few hours may not be enough to confirm, but, should have seen some wetness at the very least. What i also failed to mention here is that the bottom of the intake manifold was quite wet, and a small puddle on the driver side. I've seem them misty wet... but this was excessive, for only running a few minutes.The porous casting issue? To be honest, would this possibility not line up more with the empty bowl syndrome after leaving it for a time period? What is occurring now has more to do with constant excess fuel above and beyond the idle circuit allowances when the car is at idle.This is a bit of a long shot, but many years ago a friend had a problem with running rich, hard starting, and gas in the oil. The mechanic couldn't figure it out, so I took a stab at it. Everything looked OK, so filled the fuel bowl and let it set for a while. Sure enough empty fuel bowl and work bench had a puddle on it. Took a while, but I finally found it, a porosity in the casting on the inside edge of the fuel bowl. So, when it would set for a while the fuel would drain into the lowest point and past the rings. Every start-up required refilling the fuel bowl.

Last edited by a moderator:

- Joined

- Jan 1, 2012

- Messages

- 8,357

- Reaction score

- 1,200

- Location

- Eugene, OR

- My Car

- 1971 Mustang Sportroof M code

I agree, the porosity problem would be a leaking while setting problem. Unless, the porosity, or a void, in the casting took place between the main and idle circuits, don't even know if any of them are adjacent to get crossflow. Maybe 5 or 10 psi air pressure at various places to make sure the air comes out where it's supposed to. I've used spray carburetor cleaner to check circuits, too, but it's hard to get it in the right places without getting some blow-back in the face.

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

Going to try again today... Ordered this main metering Rod spring kit to see if the issue of too much fuel at idle can finally be resolved... The feeling is that the spring currently installed by the carb. rebuilder is too weak and the rods are not being pulled down into their seats, thereby allowing additional fuel at idle. At this stage, can really be the only issue as we triple checked everything else... Time of take the carb. off and apart...

- Joined

- Jul 12, 2010

- Messages

- 5,001

- Reaction score

- 3,006

- Location

- Killingworth, CT

- My Car

- 71 Mach 1

71 XR-7 hardtop

71 Country Squire

65 hardtop

Metering rods have no effect on the idle tuning. The rods don't "seat" in the main jets, they simply reduce fuel flow at high vacuum. The opening provided by the idle needle is minuscule compared to the jets even with the metering rods fully dropped down.

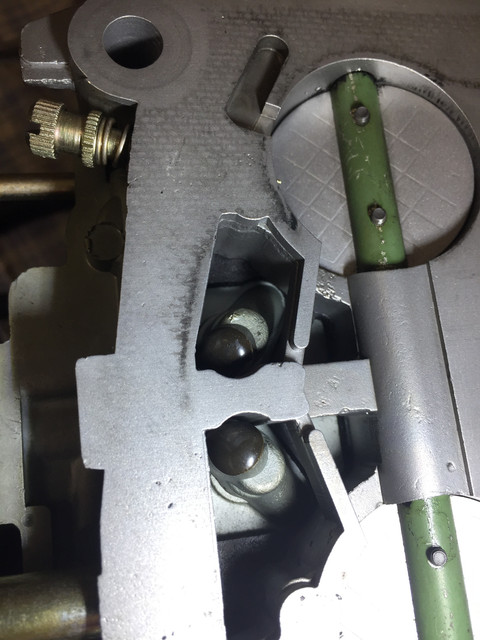

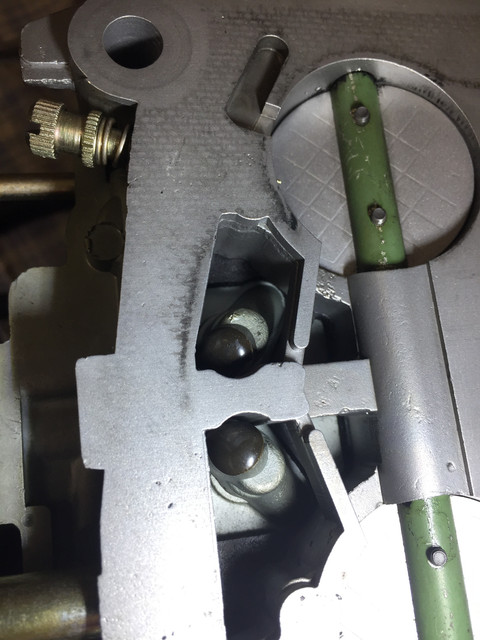

My first guess is you either have too much fuel pressure or a blocked bleed or port in your idle circuit, causing excess enrichment. You should also check the throttle blade position in relation to the off idle port as show below. If it's too high (say if you had an aftermarket cam) you should be able to open the secondaries a tad to compensate. Did you verify the 7psi reading is withing spec for the 429CJ pump? The base 429, 429SCJ and the 429CJ/PI each had their own unique fuel pumps. IIRC, the Q-jet is happier at around 5psi than the standard 7~9psi that generic "fits all" pumps provide. Check the factory shop manual for the actual 429CJ pressure spec, I don't have mine handy.

As a last resort, there's always Q-jet Cliff

https://cliffshighperformance.com/

My first guess is you either have too much fuel pressure or a blocked bleed or port in your idle circuit, causing excess enrichment. You should also check the throttle blade position in relation to the off idle port as show below. If it's too high (say if you had an aftermarket cam) you should be able to open the secondaries a tad to compensate. Did you verify the 7psi reading is withing spec for the 429CJ pump? The base 429, 429SCJ and the 429CJ/PI each had their own unique fuel pumps. IIRC, the Q-jet is happier at around 5psi than the standard 7~9psi that generic "fits all" pumps provide. Check the factory shop manual for the actual 429CJ pressure spec, I don't have mine handy.

As a last resort, there's always Q-jet Cliff

https://cliffshighperformance.com/

7173Vert

Well-known member

- Joined

- Sep 14, 2018

- Messages

- 907

- Reaction score

- 301

- Location

- Ontario

- My Car

- 1971 Convertible, 1973 Hardtop

I’ll let you know how we make out today. The fuel pump is an original, specific to the 429cj engine (Carter “X”). Appreciate the feedback. I’m aware of Q-Jet Cliffand as you note, I am keeping him as a last resort, meaning sending my carb down to him.ithink at this stage, I have to eliminate as many possibilities as possible...Metering rods have no effect on the idle tuning. The rods don't "seat" in the main jets, they simply reduce fuel flow at high vacuum. The opening provided by the idle needle is minuscule compared to the jets even with the metering rods fully dropped down.

My first guess is you either have too much fuel pressure or a blocked bleed or port in your idle circuit, causing excess enrichment. You should also check the throttle blade position in relation to the off idle port as show below. If it's too high (say if you had an aftermarket cam) you should be able to open the secondaries a tad to compensate. Did you verify the 7psi reading is withing spec for the 429CJ pump? The base 429, 429SCJ and the 429CJ/PI each had their own unique fuel pumps. IIRC, the Q-jet is happier at around 5psi than the standard 7~9psi that generic "fits all" pumps provide. Check the factory shop manual for the actual 429CJ pressure spec, I don't have mine handy.

As a last resort, there's always Q-jet Cliff

https://cliffshighperformance.com/

Last edited by a moderator:

Similar threads

- Replies

- 21

- Views

- 2K

- Replies

- 1

- Views

- 395

Latest posts

-

Parts For Sale 1973 Mustang Tilt Steering Column, Re conditioned, $800.

- Latest: 72MustangSprint

-

-

-

Wanted to tell you all About Mustang Fact Sheets at OD magazine

- Latest: 68cobraJetnotch

-

-