- Joined

- Aug 14, 2014

- Messages

- 4,312

- Reaction score

- 1,359

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

Today I went for a high performance drive during lunch break. It was hot out so I had the A/C on. While accelerating down the highway at some point I lost A/C. A few miles down it started to feel hot inside and could hear a noise from the hood. The noise went away after I turned the A/C off so definitely something was wrong. I just had accelerated to about 6,500 rpms so I had the feeling that I had overrevved the compressor. I guess I didn't think about it before. Before I had only gone to about 6,300 rpms. Once I got home I could see the mess. Oil everywhere, the high pressure hose burst, and the compression nut of the low pressure fitting was completely off. I believe that the system over pressurized and broke. The fact that the coupling nut of the fitting was off makes me think the pressure went pretty high. It was not that it unscrewed itself because that should have released the pressure and should not have caused the hose to burst. The coupling nut is aluminum so I assume that enough pressure expanded it to push it past the threads. I feel dumb now for not having thought about the RPMs of the compressor. My compressor is a York and now reading the spec it says 6,000 rpm :shootself:  . On top of that I probably had overfilled the system with refrigerant. My question now, do you think the compressor is done? Am I looking at a new compressor besides the hose? What else should I be worried about? Maybe it is time to upgrade to a whole new system from Classic Auto Air or similar? Can one of these be revved up to 6,500 rpm?

. On top of that I probably had overfilled the system with refrigerant. My question now, do you think the compressor is done? Am I looking at a new compressor besides the hose? What else should I be worried about? Maybe it is time to upgrade to a whole new system from Classic Auto Air or similar? Can one of these be revved up to 6,500 rpm?

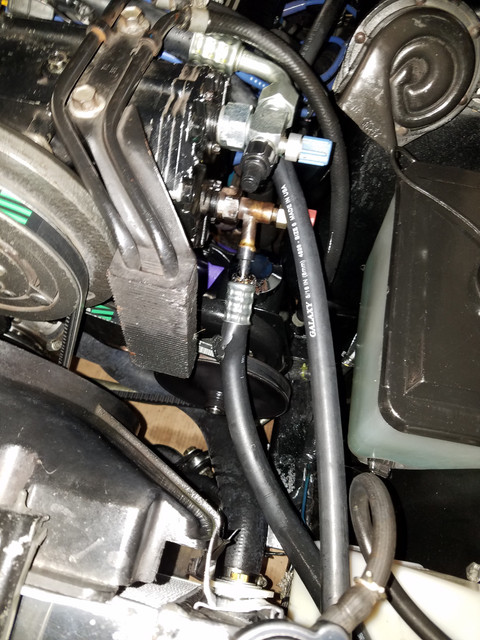

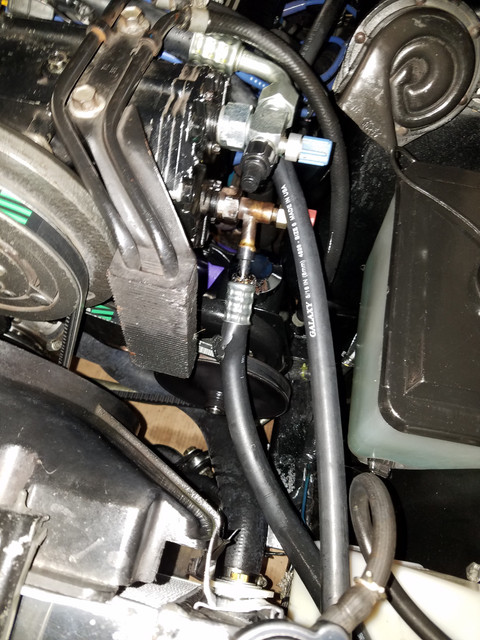

These pictures shows the burst hose. I had already screwed the low pressure fitting nut back in. As you can see the burst is coincidentally very close to the steering fluid radiator. This radiator is attached to the compressor so there shouldn't be independent movement between them, but I wonder if the hose could have moved and touched the radiator and caused it to burst, but unlikely due to how close it was to the fitting. Also, it could simply be that it was the hottest spot on the hose.

These pictures shows the burst hose. I had already screwed the low pressure fitting nut back in. As you can see the burst is coincidentally very close to the steering fluid radiator. This radiator is attached to the compressor so there shouldn't be independent movement between them, but I wonder if the hose could have moved and touched the radiator and caused it to burst, but unlikely due to how close it was to the fitting. Also, it could simply be that it was the hottest spot on the hose.