- Joined

- Aug 8, 2018

- Messages

- 375

- Reaction score

- 194

- Location

- California

- My Car

- 72 Fastback - 351C-4V, Fitech EFI, T56 Magnum 6 Speed

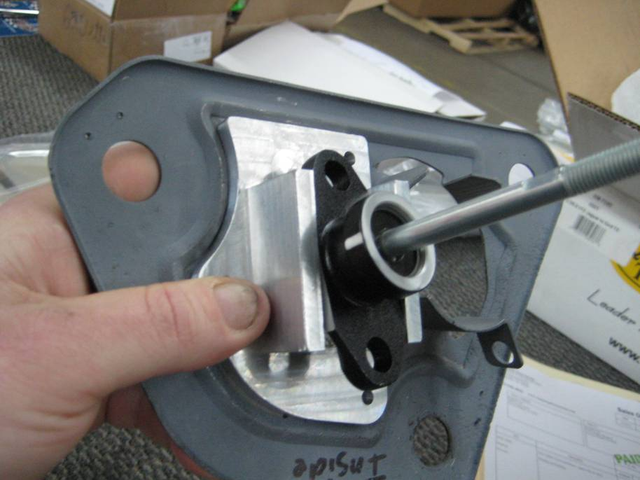

Hey guys, I'm pretty sure I know what the answer is here, but wanted to see if I'm missing something. We converted my '72 Fastback from an auto to a T56 Magnum 6 speed. To operate the clutch, we went with a Hydramax hydraulic system from American Powertrain.

It's never worked well since day one and the clutch has been VERY stiff since it was installed. But it worked enough and figured I'd circle back around to making it more drive-able once I get a few more things crossed off the list.

The other day in the driveway I was taking a look at the linkage trying to see if I could do anything to make it a bit easier to use. Didn't change anything but just pumped it 4 times to see how it felt. Very stiff and not usable, maybe even worse than before. Then I noticed that the fluid reservoir was empty and there was a pool of fluid under the car. So yea it dumped all the fluid and all at once. If I put fluid back in, it doesn't go down, but the clutch doesn't work either.

So I'm thinking the slave either over extended or just blew it's seals. Either way the trans comes off and likely needs to at least rebuild the slave. Does that sound about right? Really not wanting to have to go through all that again if I can avoid it, especially if it won't work better than before so hoping someone may see something I don't. American Powertrain has been sort of a pain to work with so wanted to check in here and see if anyone can offer any wisdom.

Thanks

It's never worked well since day one and the clutch has been VERY stiff since it was installed. But it worked enough and figured I'd circle back around to making it more drive-able once I get a few more things crossed off the list.

The other day in the driveway I was taking a look at the linkage trying to see if I could do anything to make it a bit easier to use. Didn't change anything but just pumped it 4 times to see how it felt. Very stiff and not usable, maybe even worse than before. Then I noticed that the fluid reservoir was empty and there was a pool of fluid under the car. So yea it dumped all the fluid and all at once. If I put fluid back in, it doesn't go down, but the clutch doesn't work either.

So I'm thinking the slave either over extended or just blew it's seals. Either way the trans comes off and likely needs to at least rebuild the slave. Does that sound about right? Really not wanting to have to go through all that again if I can avoid it, especially if it won't work better than before so hoping someone may see something I don't. American Powertrain has been sort of a pain to work with so wanted to check in here and see if anyone can offer any wisdom.

Thanks