The carb is a Holley 4160 (1850-3) 600 cfm with vacuum secondaries.

The distributor is a Accel 34000V single vacuum dual point unit.

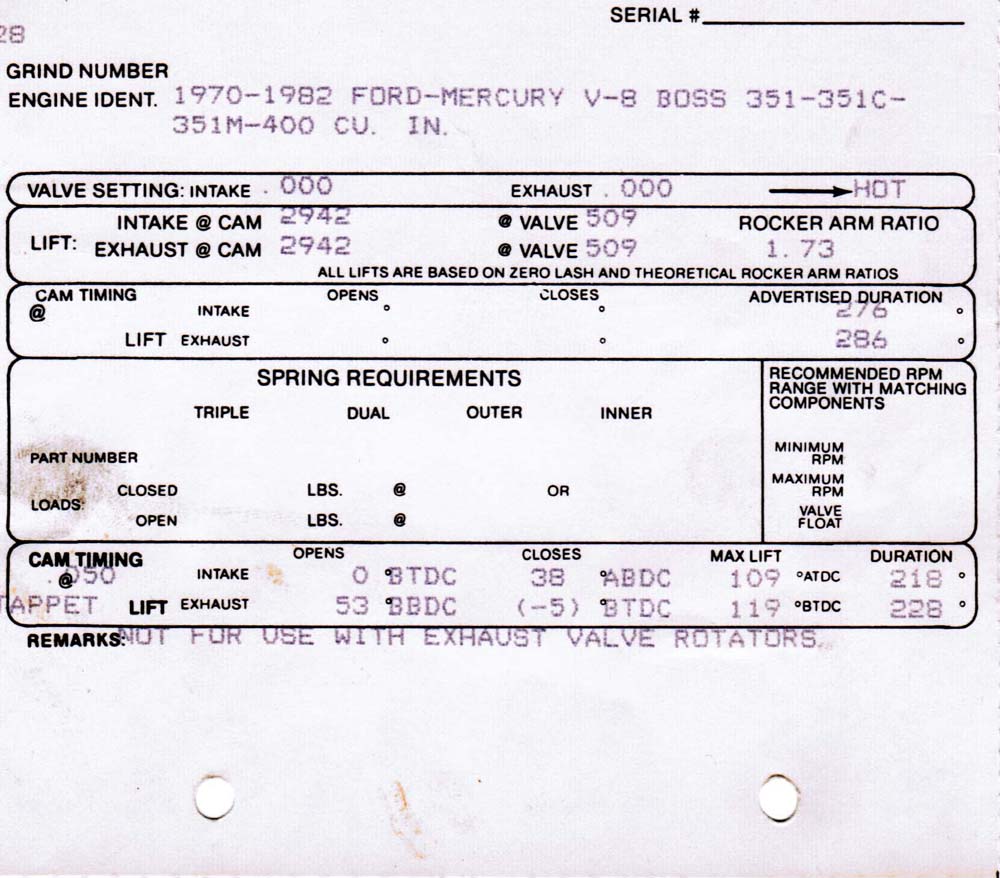

The cam spec sheet is as follows:

Can the specification of the camshaft be attributed to the idle I have?

The following is a video captured by my son. It shows the idle rpm and vacuum reading during idle.

Rpm varies between 500 and 900 while the vacuum gauge reads 9 to 12 inch Hg.

During the video, the vaccum advance was disconnected from the distributor and the initial timing was set to 6 degrees.

After I read that a vacuum leak can contribute to unstable idle I had checked for such a leak before we took the video. Initially I disconnected and plugged as many vacuum lines as possible:

- disconnected brake booster and plugged port at carburetor

- disconnected PCV and plugged port at carburetor

- disconnected vacuum line to RAM air plaps and plugged it

- disconnected vacuum line to air cleaner and plugged it

- vaccum line for distributor advance was connected to vacuum gauge

I then sprayed brake cleaner around the base of the carb where it meets the intake. Likely, I sprayed all other parts of the carb without getting any indication of a vacuum leak. Initially I had forgotten to plug the line to the air cleaner which indicated a vacuum leak by jumping the idle rpm when spraying near the open end.

As you can easily see, I'm far from achieving a steady idle. Do I still have a vacuum leak I didn't find, is it the duration of the camshaft or something else?

I will follow the procedure outlined above by Chuck tomorrow.

Thank you, Manfred