JRANGER

Well-known member

- Joined

- Jun 4, 2018

- Messages

- 143

- Reaction score

- 2

- Location

- TENNESSEE

- My Car

- 73 Hardtop 302/c4

65 Fastback

So i know people say it wont fit but i had one laying around and love the look of it.

So its not finished but i figured i would share how things are going.

FIRST AND FOREMOST: If you are worried about the the 73's safety/crash rating this may not be for you. I am not an engineer and do not gurantee any structural integrity. However this should be better then a fiberglass bumper.

Needs: Angle Grinder with cut off wheels, Drill Press or Drill, stepper bit, Grade 8 bolts, washers, nuts, grinding bit to widen bracket holes(maybe)

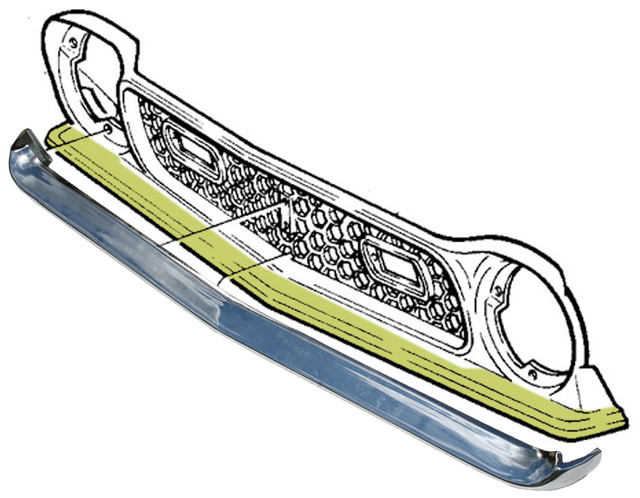

1) I cut the bumper brackets off. You have to notch the structure from the edge to about an inch away from the hole seen below: You need to cut along where the urethane meets the metal. Get as close as possible

2) You will need a good piece of angle iron. About 36" long. It goes from the inner hole on each bracket. You will need to make at least 4 holes. 1 set for the frame brackets and one set for the bumper. I made 6, as there are 4 holes on the bumper bracket as is. I made these holes oversized for as much adjustment as possible. The angle iron will sit on top of the bumper bracket .

You also may considering drlling several small holes from one side to the other. The purpose of this would be once everything is fit properly you can use self tapping screws to keep the angle in the right place for welding in place without worrying about it shifting.

3) You have options here. I believe there is room to drill a new hole above the top slot but it will be tight. I didnt think about this and just started wallowing out the hole for adjustments. I am going to make a plate on the back of it when its all done and weld in place. As you see below i have started this process but the bumper currently sits a little too far to the drivers side and needs to come up about a 1/4" The angle iron should sit close to even with the top edge

Also you will want to not atleast the bottom outside edge of each bracket otherwise the bottom of the urethane bumper will hit it

I hope to get as final fitment next weekend but i just wanted to share the results so far.

aluminium oxide molar mass

So its not finished but i figured i would share how things are going.

FIRST AND FOREMOST: If you are worried about the the 73's safety/crash rating this may not be for you. I am not an engineer and do not gurantee any structural integrity. However this should be better then a fiberglass bumper.

Needs: Angle Grinder with cut off wheels, Drill Press or Drill, stepper bit, Grade 8 bolts, washers, nuts, grinding bit to widen bracket holes(maybe)

1) I cut the bumper brackets off. You have to notch the structure from the edge to about an inch away from the hole seen below: You need to cut along where the urethane meets the metal. Get as close as possible

2) You will need a good piece of angle iron. About 36" long. It goes from the inner hole on each bracket. You will need to make at least 4 holes. 1 set for the frame brackets and one set for the bumper. I made 6, as there are 4 holes on the bumper bracket as is. I made these holes oversized for as much adjustment as possible. The angle iron will sit on top of the bumper bracket .

You also may considering drlling several small holes from one side to the other. The purpose of this would be once everything is fit properly you can use self tapping screws to keep the angle in the right place for welding in place without worrying about it shifting.

3) You have options here. I believe there is room to drill a new hole above the top slot but it will be tight. I didnt think about this and just started wallowing out the hole for adjustments. I am going to make a plate on the back of it when its all done and weld in place. As you see below i have started this process but the bumper currently sits a little too far to the drivers side and needs to come up about a 1/4" The angle iron should sit close to even with the top edge

Also you will want to not atleast the bottom outside edge of each bracket otherwise the bottom of the urethane bumper will hit it

I hope to get as final fitment next weekend but i just wanted to share the results so far.

aluminium oxide molar mass

Last edited by a moderator: