- Joined

- Nov 15, 2010

- Messages

- 935

- Reaction score

- 19

- Location

- annapolis-maryland

- My Car

- 73 Mustang Convertable

Ok Gang, Here's the plan.

I getting ready to upgrade my stereo sound. Not that what I have is bad, by any means. I've got Kickers : 5 x 8's in the door and 6's in the rear side panels. With a nice Sony head unit pushed with a Kicker 4 channel amp. Cruising with the top down, I don't even realize how high I have it cranked until I stop. We live at the end of a 1/4 mile road, and the misses says she can hear it over the mufflers when I make the turn onto it.

BUT

In my daily driver,2006 Chevy HHR, I have a nice Sub Woofer and tweeters in the A-Pillars. I drive 1 to 1/2 hours each way to work and back, and I have a Gazillion albums loaded onto a I-Pod touch that I usually just have on shuffle the whole time. Except when I really want to rock on

So I am going to put Tweeters in the A-Pillars of the Mustang and a Sub Woofer in the trunk.

This thread is going to be a progress report for the Tweeters. I contemplated waiting until everything was done and then posting a synopsis, but I figured maybe some here might like to ride along during the trip.

I actually looked at mounting the tweeters in the dash face or top. But I didn't think that I'd get the sound I want, and I couldn't bear to drill openings for them. And, there is no way that I am going to modify the stock A-Pillars. That would be unforgivable. .

.

So I did a little searching on the net and found various forum threads where people modified their ricers in a multitude of different ways. I really like the technique that I'm adapting.

I also figured that I need some practice before plunging right into the Mustang, so I'm going to use my 1996 F350 Dually (non-superduty) as a Guinna pig. If everything goes as planned the Mustang should be easy.

Here's where they are going to go.

The idea is to build the housings out of fiber glass that will fit over the pillars, and although probably not look like original, hopefully will not be obnoxious.

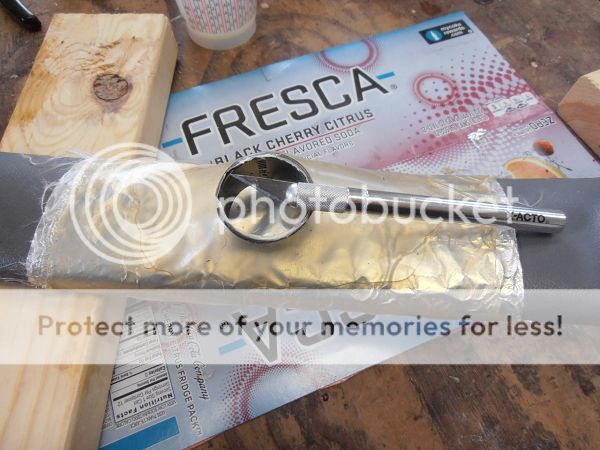

Using aluminum foil to protect the pillars from the glass.

Laying out the glass cloth.

And here is the first coat of resin applied

Put another layer of cloth on while the resin was still setting up, and added more resin.

To be continued ::chin:

I getting ready to upgrade my stereo sound. Not that what I have is bad, by any means. I've got Kickers : 5 x 8's in the door and 6's in the rear side panels. With a nice Sony head unit pushed with a Kicker 4 channel amp. Cruising with the top down, I don't even realize how high I have it cranked until I stop. We live at the end of a 1/4 mile road, and the misses says she can hear it over the mufflers when I make the turn onto it.

BUT

In my daily driver,2006 Chevy HHR, I have a nice Sub Woofer and tweeters in the A-Pillars. I drive 1 to 1/2 hours each way to work and back, and I have a Gazillion albums loaded onto a I-Pod touch that I usually just have on shuffle the whole time. Except when I really want to rock on

So I am going to put Tweeters in the A-Pillars of the Mustang and a Sub Woofer in the trunk.

This thread is going to be a progress report for the Tweeters. I contemplated waiting until everything was done and then posting a synopsis, but I figured maybe some here might like to ride along during the trip.

I actually looked at mounting the tweeters in the dash face or top. But I didn't think that I'd get the sound I want, and I couldn't bear to drill openings for them. And, there is no way that I am going to modify the stock A-Pillars. That would be unforgivable.

So I did a little searching on the net and found various forum threads where people modified their ricers in a multitude of different ways. I really like the technique that I'm adapting.

I also figured that I need some practice before plunging right into the Mustang, so I'm going to use my 1996 F350 Dually (non-superduty) as a Guinna pig. If everything goes as planned the Mustang should be easy.

Here's where they are going to go.

The idea is to build the housings out of fiber glass that will fit over the pillars, and although probably not look like original, hopefully will not be obnoxious.

Using aluminum foil to protect the pillars from the glass.

Laying out the glass cloth.

And here is the first coat of resin applied

Put another layer of cloth on while the resin was still setting up, and added more resin.

To be continued ::chin:

Last edited by a moderator: