- Joined

- Oct 31, 2018

- Messages

- 160

- Reaction score

- 0

- Location

- KY

- My Car

- 1973 Mach 1

work in progress

302 automatic

[url=https://ibb.co/cwk3bw3][img]https://i.ibb.co/DYzWGYW/IMG-3420.jpg[/img][/url]

[url=https://statewideinventory.org/used-cars]statewide auto sun valley[/url]

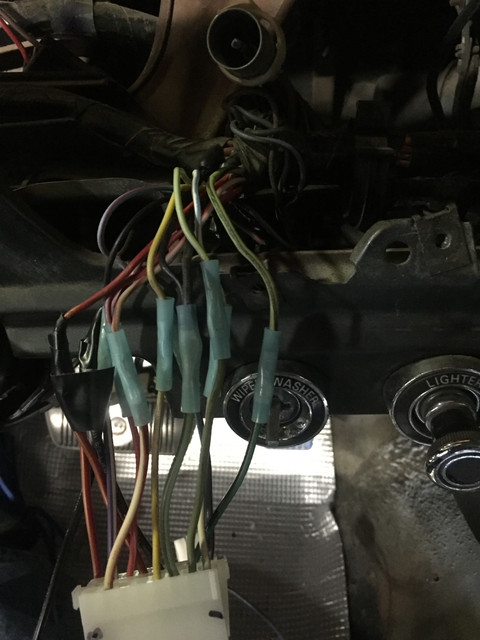

I install my new tank, new sending unit and put 5 gallons in 20 gallon tank. My gauge still reads Empty. I checked sending unit with ohms meter before installing it and it rwad like 9 to 68 empty to full. The old sending unit reads 6 to 48.

I got the gauge to jump to full one time with old sending unit once. Does tank need to be grounded? I put thin rubber pads between top of tank and trunk floor.

I tried putting a jumper across the 2 terminals on the plug at tank but gauge stayed on empty.

How should I go about trouble shooting this?

thanks

Bob

I got the gauge to jump to full one time with old sending unit once. Does tank need to be grounded? I put thin rubber pads between top of tank and trunk floor.

I tried putting a jumper across the 2 terminals on the plug at tank but gauge stayed on empty.

How should I go about trouble shooting this?

thanks

Bob