- Joined

- Aug 14, 2014

- Messages

- 4,310

- Reaction score

- 1,355

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

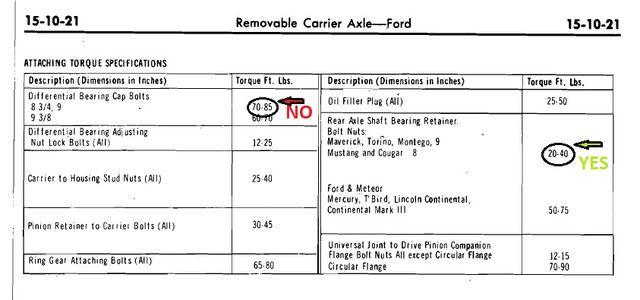

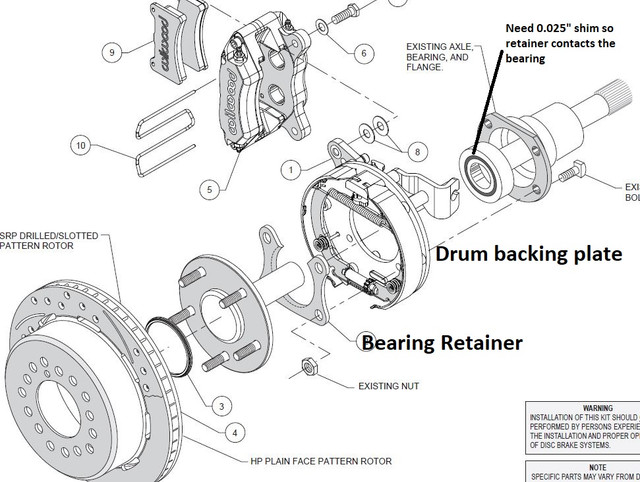

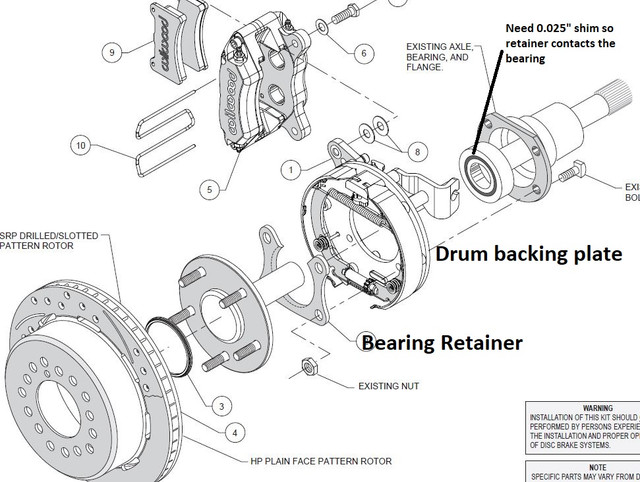

I am installing the Wilwood 140-11403 disc brake kit for the rear. This one has a drum e-brake that doubles as a backing plate. The drum brake backing plate goes flush against the axle flange and then there is a bearing retainer that has an inside folded lip that should retain the bearing. The problem is that this folded lip is about 0.025" short of contacting the bearing. I have new axles/bearings from Strange. Called Wilwood and they say that it should work, but it doesn't. Strange says that this are standard bearings. I found one thread online where the person was having a similar issue. As a background, I did make sure the backing plate and flange are clean and flushed. I did measurements before the installation because I was suspicious of the problem and then confirmed the problem after installation.

In any case, i need to move forward and find a solution. The easiest would be to find a shim or washer that I could fit in that opening. It would have to have a diameter larger than 2.64" ID and less than 2.95" OD. The thickness is not that critical because if it is thicker I could shim the bearing retainer plate. Needless to say I can't find anything for that application. I am hoping someone has an idea of a shim/washer for another application that has similar dimensions that I can make work. Even if the OD is larger I could grind it down. It doesn't need to have a perfect OD as long as the thickness is constant. Heck, I even looked at a 67mm camera filter adapter that I may be able to make work. Looking for ideas. Thanks.

Here is the diagram from Wilwood:

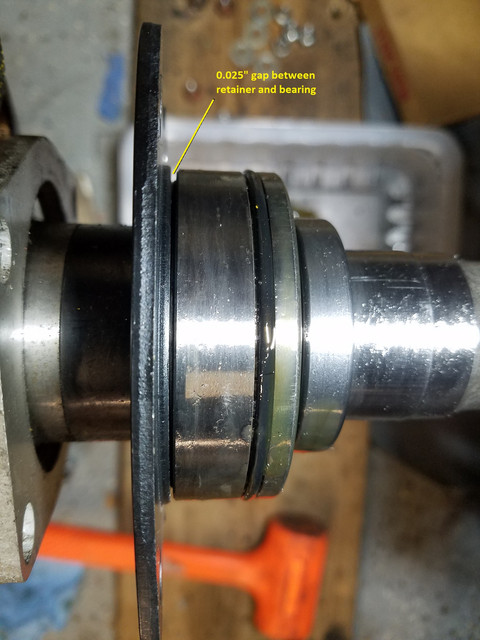

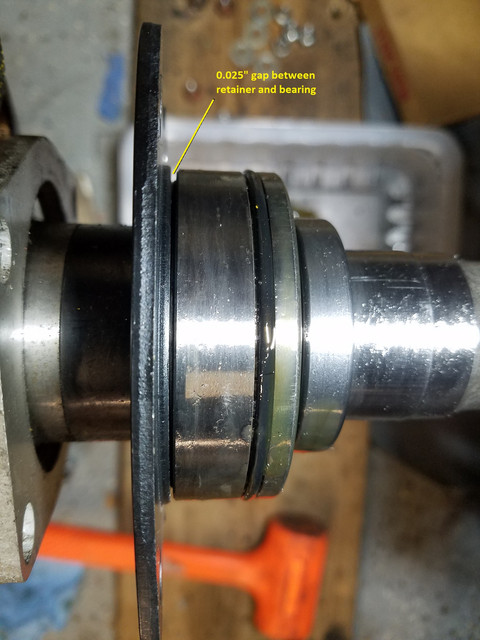

Picture of gap between bearing retainer and bearing:

In any case, i need to move forward and find a solution. The easiest would be to find a shim or washer that I could fit in that opening. It would have to have a diameter larger than 2.64" ID and less than 2.95" OD. The thickness is not that critical because if it is thicker I could shim the bearing retainer plate. Needless to say I can't find anything for that application. I am hoping someone has an idea of a shim/washer for another application that has similar dimensions that I can make work. Even if the OD is larger I could grind it down. It doesn't need to have a perfect OD as long as the thickness is constant. Heck, I even looked at a 67mm camera filter adapter that I may be able to make work. Looking for ideas. Thanks.

Here is the diagram from Wilwood:

Picture of gap between bearing retainer and bearing: