- Joined

- Sep 16, 2017

- Messages

- 78

- Reaction score

- 2

- Location

- Australia

- My Car

- 1973 Mach 1 - matching numbers, 25,000 miles Eleanor look-a-like

[url=https://ibb.co/mvrntk][img]https://preview.ibb.co/bG8YYk/1_lr.jpg[/img][/url]

[url=https://ibb.co/dwgntk][img]https://preview.ibb.co/fEZ7tk/2.jpg[/img][/url]

[url=https://imgbb.com/]picture hosting websites free[/url]

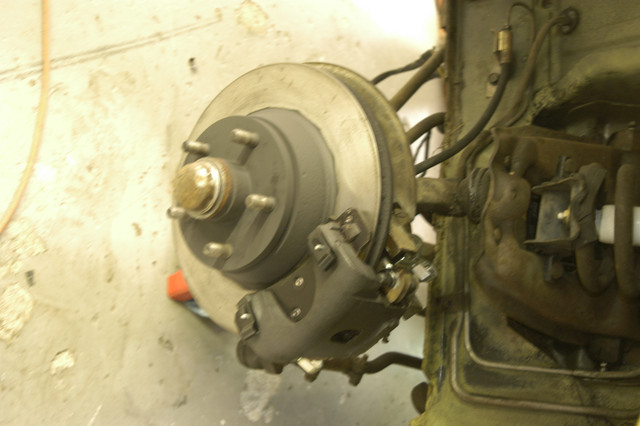

Hi Guys, need to replace the upper ball joints which are riveted in - there's some long-term thinking there!!

So looks like we need to drill them out, to get drill access looks like we have to swing the spring/shock assembly inwards and at this point we can't get these lower bolt heads to budge ( :huh: ) and wanting to be careful not to burr them. Can anyone tell me if the nuts under are captive or will they take a socket - can't get good visibility (a hoist, oh to dream)?

I'm guessing a few of you guys must have done this job - can't find a thread on them, sorry if I missed it, just point me to it so I don't waste anyone's time.

Thanks, in advance, for your time and thoughts on this.

So looks like we need to drill them out, to get drill access looks like we have to swing the spring/shock assembly inwards and at this point we can't get these lower bolt heads to budge ( :huh: ) and wanting to be careful not to burr them. Can anyone tell me if the nuts under are captive or will they take a socket - can't get good visibility (a hoist, oh to dream)?

I'm guessing a few of you guys must have done this job - can't find a thread on them, sorry if I missed it, just point me to it so I don't waste anyone's time.

Thanks, in advance, for your time and thoughts on this.

Last edited by a moderator: