This thread is of interest to myself as I have got the same heads and inlet, one thing I do remember reading when I was trying to decide on a cam was that if the exhaust valve was not opened early enough ( around 80 to 84 BBDC ) it can cause the top end torque to drop off like a brick at higher RPM's (

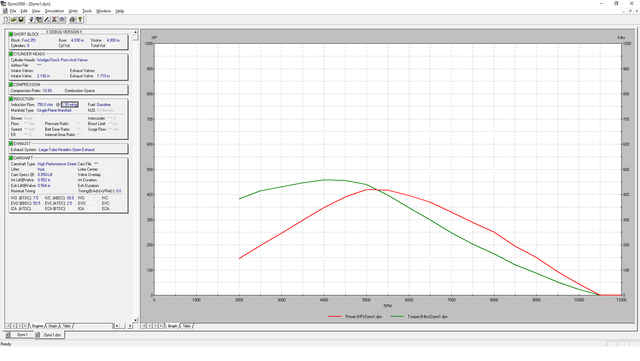

https://pantera.infopop.cc/topic/sticky-3-351c-basics-and-performance-tuning ). Being that your cam opens fairly late ( 72 BBDC on a lunati 62503 ) it could be a contributing factor, I can imagine having a larger capacity would also make this a little worse ( more gasses to get out ).

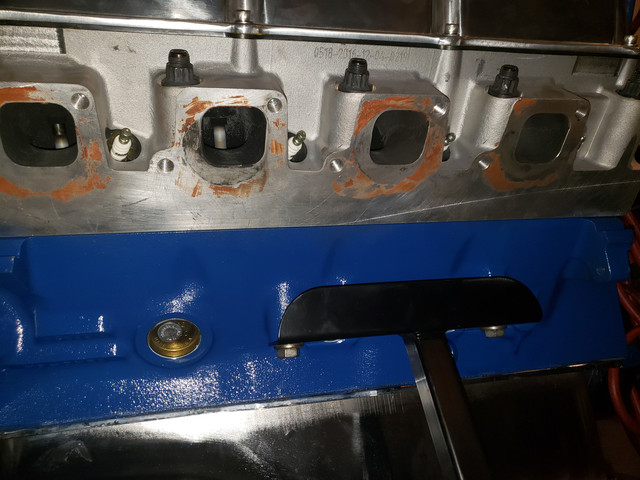

As for the heads I found that they needed a little work in the chambers, they needed a bit of work around the valves as the valve area is a little shrouded, the chambers needed CC'ing and pointy bits needed removing and also a lot of casting flash needed removing in the ports ( most of this work is not needed on the CnC'd heads ).

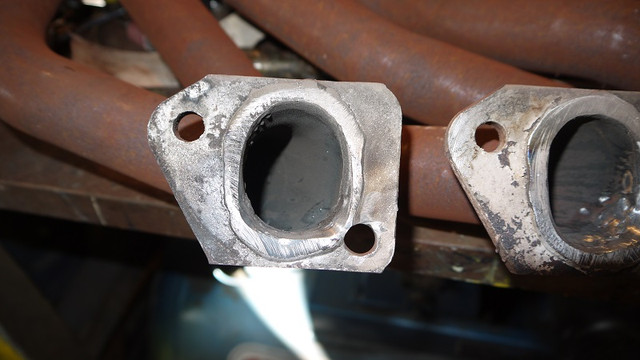

And lastly I have read that the inlet is not that good with a carb as with it being a low rise open plenum it can suffer from fuel drop out due to turbulence and poor port velocity but this mainly happens at low RPM ( to get around this myself I am going sequential EFI with a drilled manifold ).