- Joined

- Mar 30, 2017

- Messages

- 2,389

- Reaction score

- 883

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

As I have no idea how the engine was when all together, and as I don't know much on 429 (tho learning daily). I can't find any doc on this, neither close ups picts of this setup.

So may be one of you can clarify this for me...

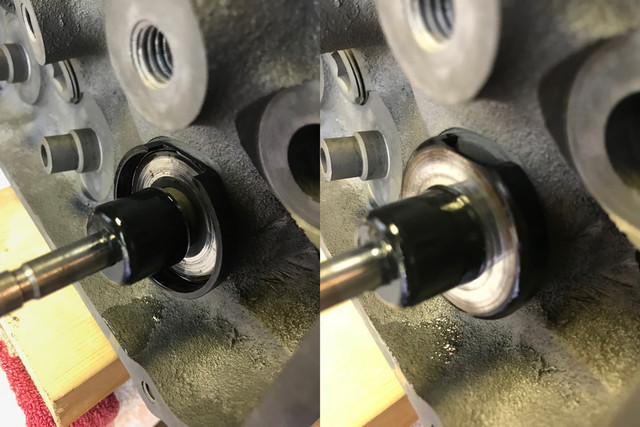

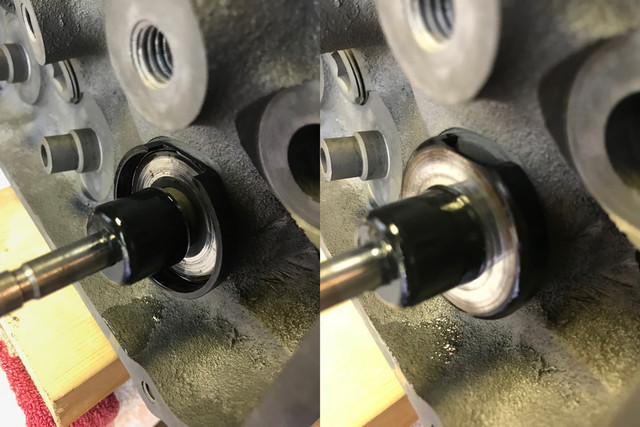

On my DOOE-R CJ heads, there is a spacer between springs and heads.

Reusing the originals, from the patina, I can see the larger part is in contact with the heads. (on the left on pict), I see the valves stems seals do not go down to the spacer thickness. If I would invert the spacer (on the right) then they would match the height of the spacer. seals would then seal. (They are not forced/tapped here on the pict, just pushed in for the picts)

I don't think right is correct orientation for the spacer, but it makes me wonder if the seals are the right ones,... I've ordered them for a 429, and the previous ones, (tho not originals) are of the exact same shape. They fit the valves stems nicely but are they long enough? I see the exact same ones at Summit for 429/460 applications. but the engine being CJ, I wonder if there would be a specific diff on those.

Also as I might be missing more parts than I thought, why is that spacer having this opening?

Is there something I need to have (that I miss, something that prevents it to rotate??) that would match this opening or is this shape there just ment for oil to enter the "cup" easilly and lubricate the spring at the base?

or am I all good on left side, and it's just how short the stems seals are and that opening on the spacer is a just an oil passage?

thx by advance.

So may be one of you can clarify this for me...

On my DOOE-R CJ heads, there is a spacer between springs and heads.

Reusing the originals, from the patina, I can see the larger part is in contact with the heads. (on the left on pict), I see the valves stems seals do not go down to the spacer thickness. If I would invert the spacer (on the right) then they would match the height of the spacer. seals would then seal. (They are not forced/tapped here on the pict, just pushed in for the picts)

I don't think right is correct orientation for the spacer, but it makes me wonder if the seals are the right ones,... I've ordered them for a 429, and the previous ones, (tho not originals) are of the exact same shape. They fit the valves stems nicely but are they long enough? I see the exact same ones at Summit for 429/460 applications. but the engine being CJ, I wonder if there would be a specific diff on those.

Also as I might be missing more parts than I thought, why is that spacer having this opening?

Is there something I need to have (that I miss, something that prevents it to rotate??) that would match this opening or is this shape there just ment for oil to enter the "cup" easilly and lubricate the spring at the base?

or am I all good on left side, and it's just how short the stems seals are and that opening on the spacer is a just an oil passage?

thx by advance.

Last edited by a moderator: