That looks sharp. When you say polyester, what specifically did you use, how thick and where might I find some?

First lets talk shape if you do not go for the aluminium. To get a flat shape that wide in polyester that looks good when painted is hard, normally you must do a negative from a positive based on flat surfaces, add details then make a positive from it. But this shape can be done in one go as a negative and with nothing in it that prevents you to extract the part from the mould once done.

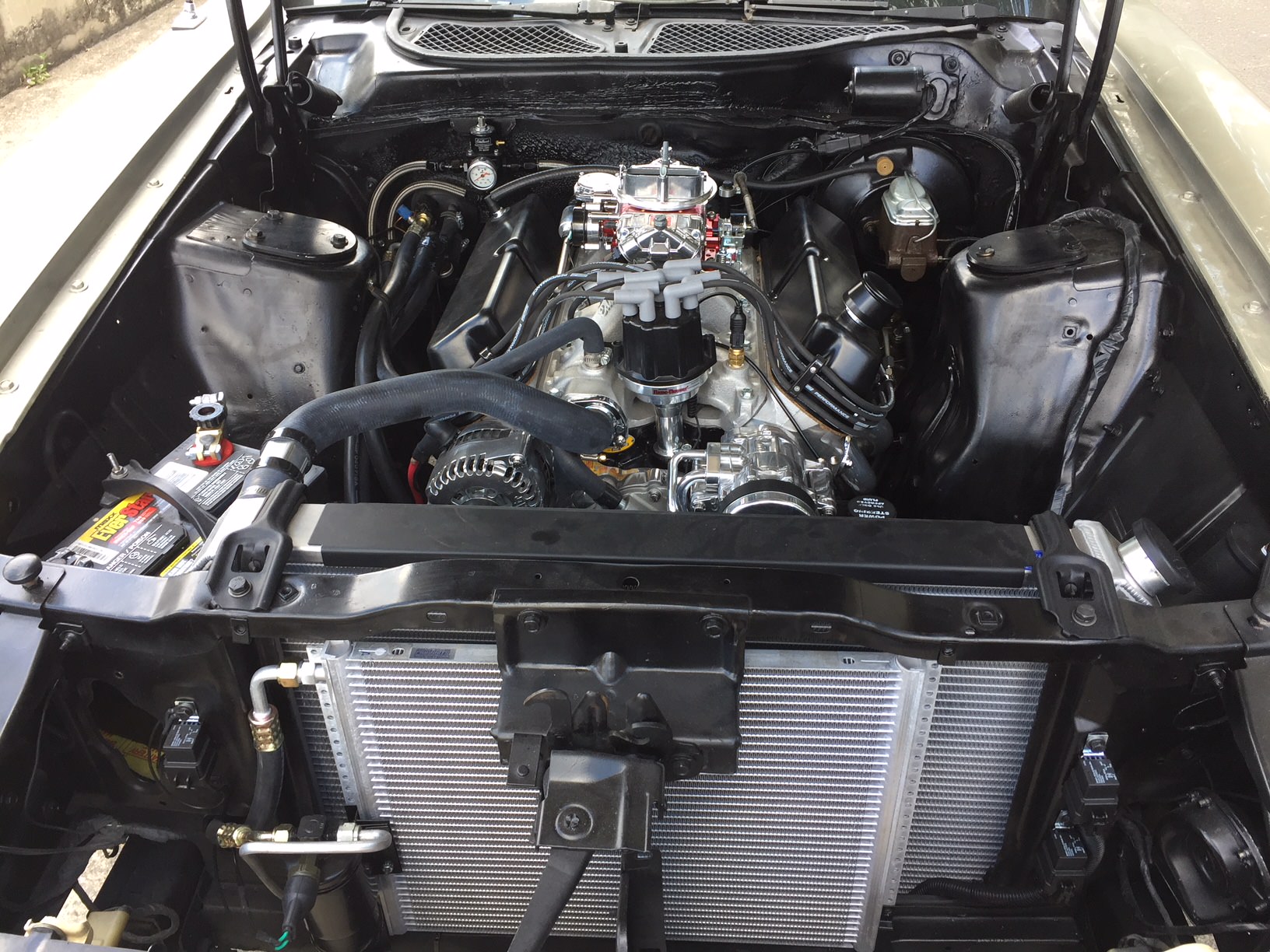

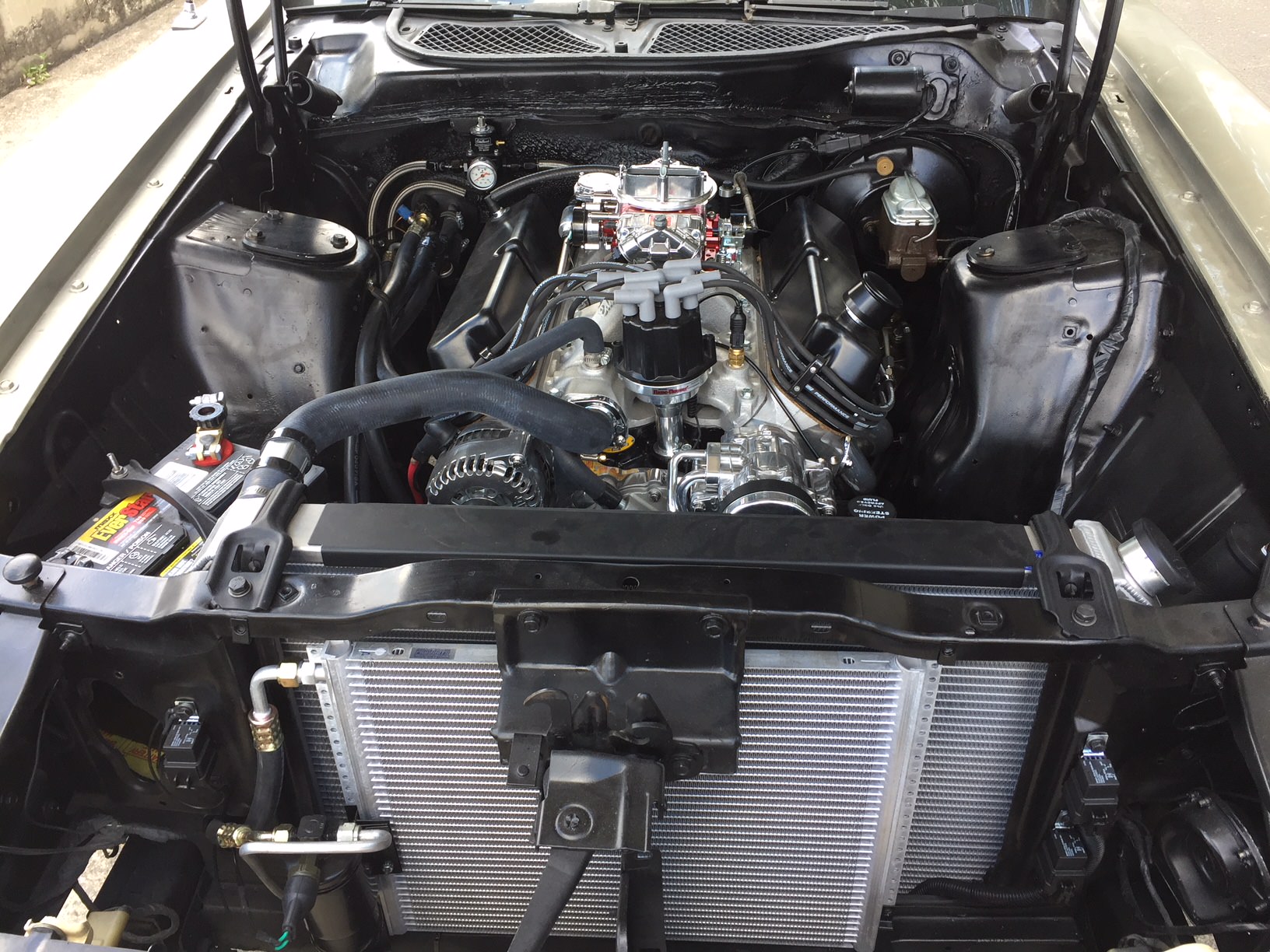

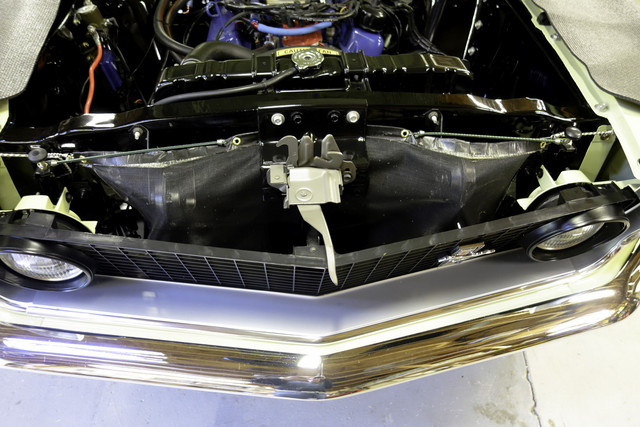

So for the mould I've used simple MDF plates, but instead of making the radiator side going up, it went down. I was then milled the corner, to have a nice smooth rounded corner when you that this almost 90 deg angle, then because I wanted to hide the latch and have a lower surface to include the gauges. For the gauges I've cut the shape I wanted, milled the corners and glued it on the plate (so a higher level in negative means lower level in positive). For the latch cover that needs be higher in the final piece, I did the reverse and cut a hole using a shape defined on the car latch to define its contours with another cardboard. From the other side milled it and screws a thin plate underneath that would define the top of the cover. The milling here must be done from the other side at same angle otherwise you will never get that part out the mould without damage. Its also nice to have the same angle at the edges on the final shape.

Then sprayed thick primer and sanded it. At this point I got a perfect negative of the shape I wanted in one go.

Once the surface was smooth, used polyester wax, and then rolled 2 layers of gel coat with few hours of interval. (that gives you the hard and smooth surface that you see on boats) Once dry, poured polyester resin and applied fiberglass fibers, pre cut for the shape and did that twice. All fiber was hand cut so there is not much overlap to keep the thickness almost same everywhere. Rolled till I could no more see air bubbles and waited. The final piece is +-4 mm thick and fairly strong, More than enough for its purpose once bolted on the car.

At the end of that weekend, drilled at a corner a hole near the gel coat and blew some compressed air, my part popped up. Then simply needed to cut 2 holes for the gauges with a rotating saw, cut the contour in front by placing the grille on it, same for the radiator side and the latch hole. A short sanding and polishing session and my part was ready.

Using a plate of aluminum is much more easy to make.A basic flat cover is a 2 hours max job and it looks very nice. But with gauges and latch regions, that I wanted, this simple shape is very confusing as everything is the opposite of what you want and will cost you a weekend, but then you are good for 25 years and more

Its 3 am here, so I'm not sure what I wrote is clear. I'll post more picts and some drawing later on if you guys are interested.