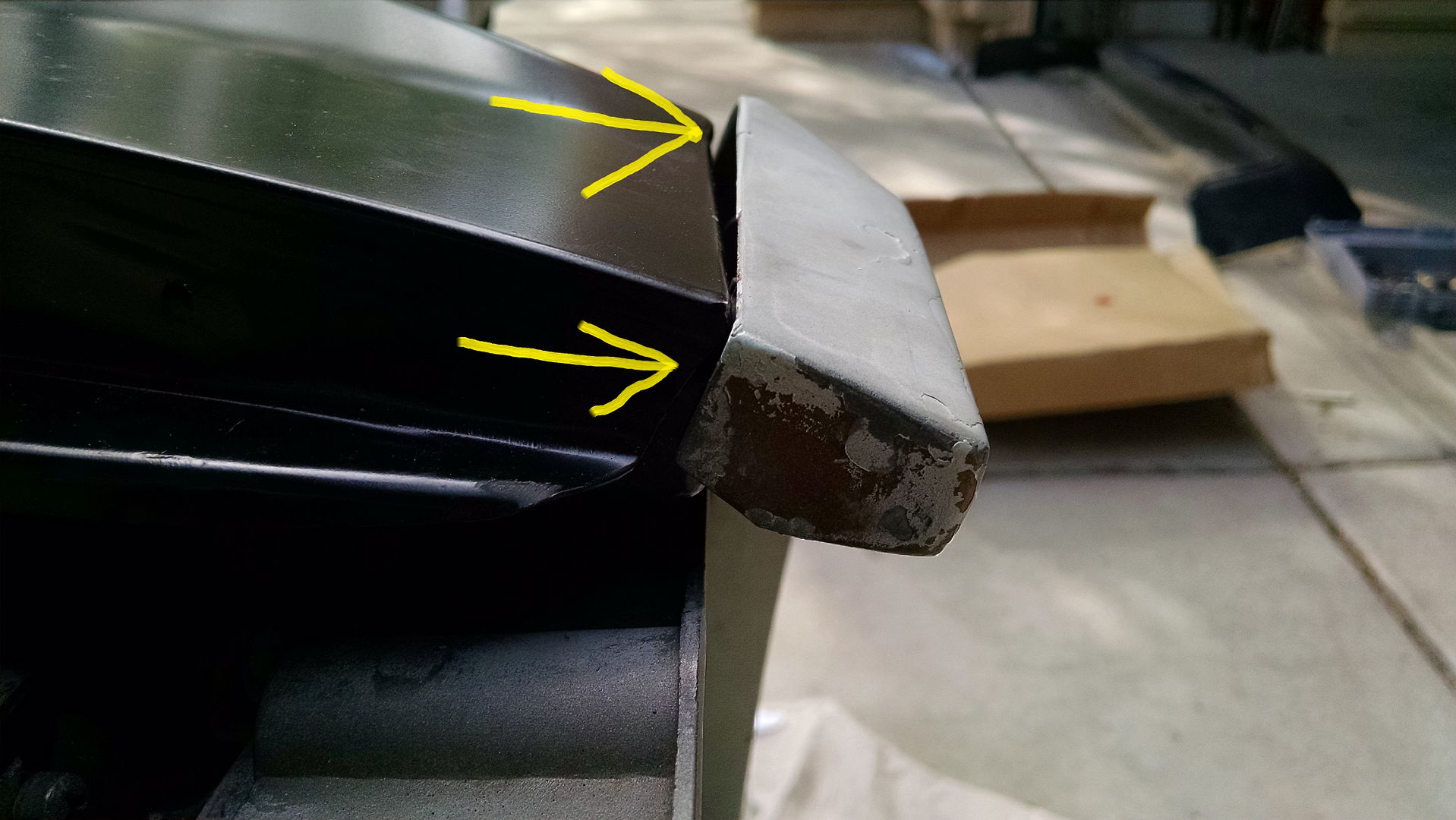

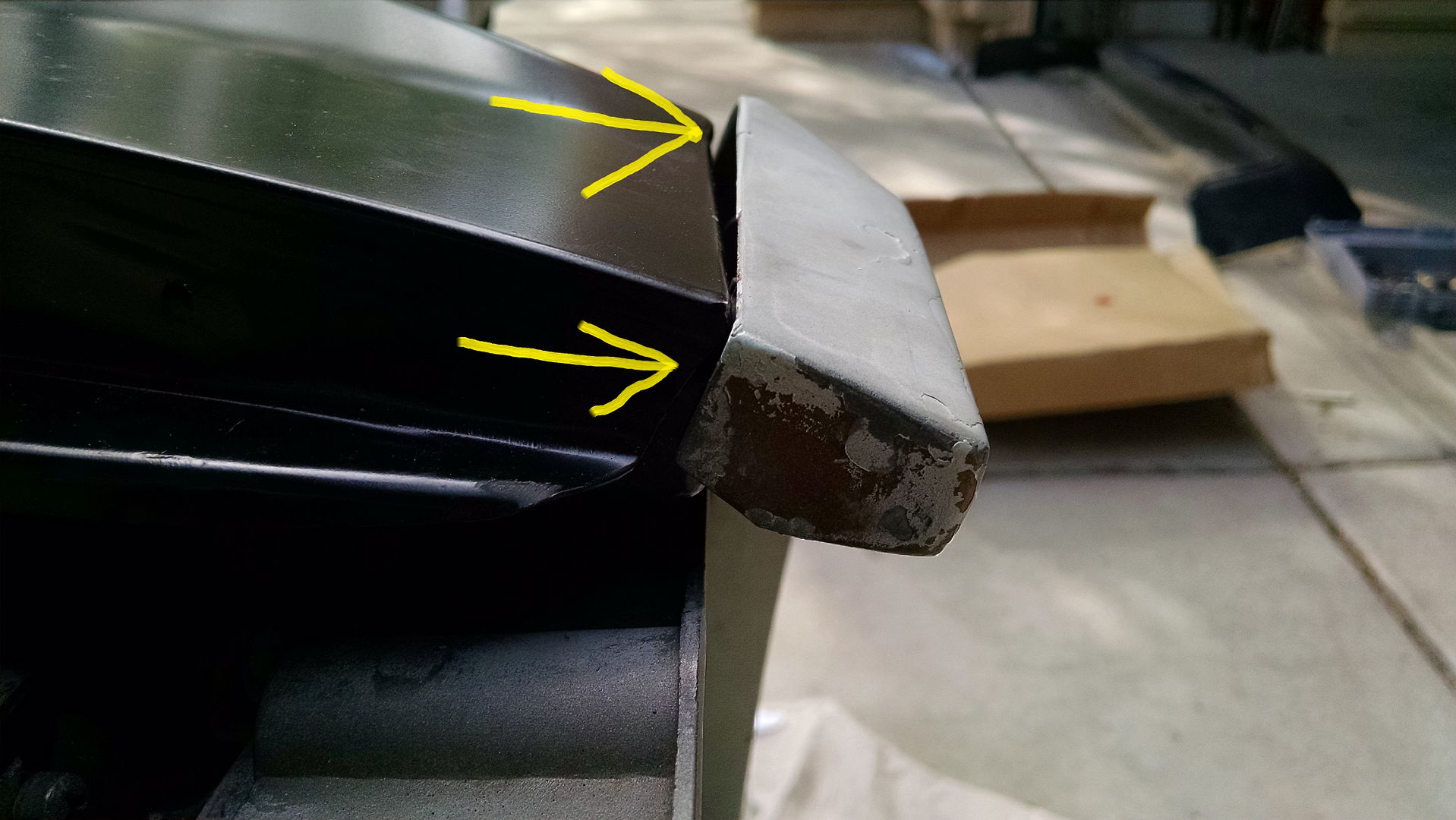

I thought people were kidding when they would tell me their horror stories about panel fit. It does not seem to matter who made the panels or for what vehicle they get some strange parts out of the tooling. A friend that does high end restorations, over $100,000 us a usual cost was telling me some of his horror stories. He did a 1968 428 CJ for a local. They ordered a repo fender from Dynacorn and when it was all said and done he had to remove and inch from the length of the fender to get it on the car.

He was doing a 69 Camaro coupe that needed quarters on both sides. He got the right one on with some pain but when he went to the left one nothing fit. With a tape measure there was 2.0" difference from the right. When he called the supplier they said there is not way it can be off that much. They sent him another and it fit. He sent the other one back and they called and apologized because after they got it and measured they agreed with him.

He also did a Pontiac GTO and got repo rear quarters that he could never use they were an inch off in the front. NOS GTO quarters go for $6,000 to $8,000 each if you can find them. He has a Left if anyone looking.

I was a automotive tooling engineer for the last 25 years and I do not know how they can be so far off. I guess if all you are doing is setting up an existing fender and doing a laser scan to build the tooling it can be twisted out of shape. You would think Ford would work with them to get old drawings so they could fixture the parts to scan correctly.

There are horror stories on youtube where they are off over an inch on mustang parts. I am sure they cut corners on the tooling and probably eliminate half the hits to save money on the tooling.

I was told if you use repo you just have to learn to live with the crap you get. There should still be lots of good original front fenders out there go look for Ford steel.

David