andy72

Well-known member

- Joined

- Jul 3, 2014

- Messages

- 253

- Reaction score

- 23

- Location

- california, ca

- My Car

- 1972 mach 1 351 ram air

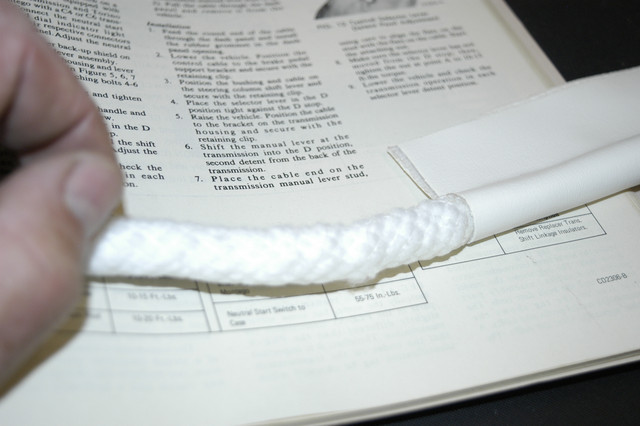

[url=https://ibb.co/R9rNbJs][img]https://i.ibb.co/376vdPj/DSC06636.jpg[/img][/url]

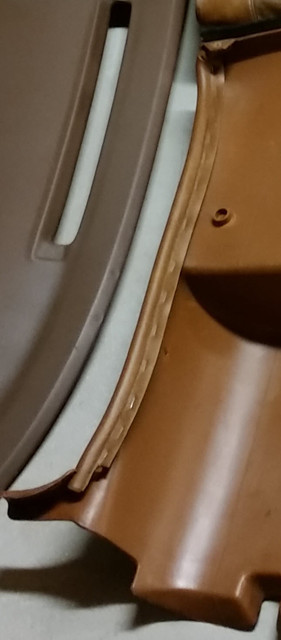

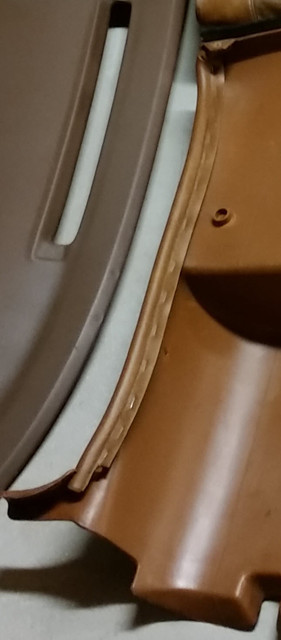

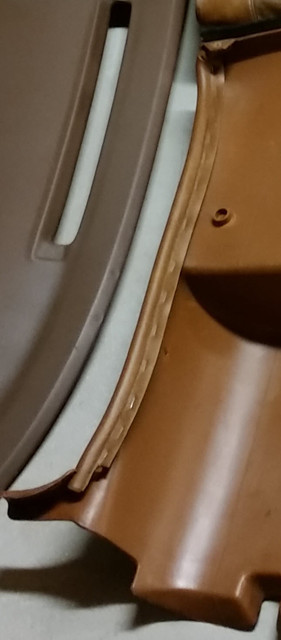

My weatherstripping is stapled on also.Staples will probably break the old plastic. The weather stripping just clamps on, the windlace will need some glue to hold it in position. It does not need a lot, just a thin bead on the inside of the windlace. Avoid any of the foaming polyurethane glues as they will make a mess.

I stapled mine with a bostitch plier type stapler. It worked great. Went thru the wind-lace and plastic panel with ease.I'm don't see myself going down the stapler road. I don't need it that correct inside the quarter area where it can't be seen.

I'm still looking for the light to go off in my head though on the weatherstrip attach method though...

Andy

Thanks for that. I'll look into one. Did you happen to do your weatherstripping on this panel also? My strips are stapled on...I stapled mine with a bostitch plier type stapler. It worked great. Went thru the wind-lace and plastic panel with ease.I'm don't see myself going down the stapler road. I don't need it that correct inside the quarter area where it can't be seen.

I'm still looking for the light to go off in my head though on the weatherstrip attach method though...

Andy

I di not replace the weatherstrip on mine but it should have no problem putting the staples thru it. I think the difficulty will be clearing the fold (the "V") in the rubber strip with the stapler.Thanks for that. I'll look into one. Did you happen to do your weatherstripping on this panel also? My strips are stapled on...I stapled mine with a bostitch plier type stapler. It worked great. Went thru the wind-lace and plastic panel with ease.I'm don't see myself going down the stapler road. I don't need it that correct inside the quarter area where it can't be seen.

I'm still looking for the light to go off in my head though on the weatherstrip attach method though...

Andy

Enter your email address to join: