- Joined

- Aug 14, 2014

- Messages

- 4,320

- Reaction score

- 1,367

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

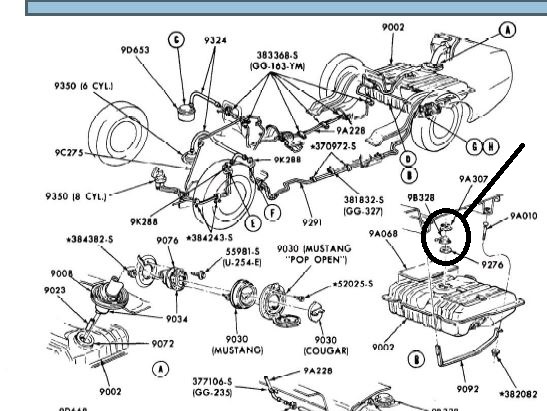

Adam,Awesome thank you for the diagram. So the thing you've circled is the sending unit correct? I've looked at the part, here http://www.cjponyparts.com/fuel-tank-sending-unit-1971-1973/p/FSU4/ but can't seem to figure out where the vent orifice is (I'm new to all this thanks for your patience).. And what you're saying is to add a second sending unit to use for the return line? I was planning to do the install without removing the tank, but if I'm going to have to take it out regardless do you guys think I should abandon the surge tank setup and go with an in-tank pump like a Tanks Inc one instead?Don and Iceberg are spot on. The nipple of the vent cap on top of the gas tank has a small orifice that reduces the diameter of the conduit. Therefore, you have to either drill the nipple or use a stock sending unit in its place. The sending unit fits right on and you can use its tubing to connect the vapor line. Whichever way you decide to go you will have to take the tank down, which should be a very easy task. The worst part of the job is draining the gasoline, specially if your tank is not empty.A little lost trying to understand what you're saying. The orifice on the gas tank is too small to act as a return for the RobbMC PS tank? And the vented gas cap won't be able to prevent the gas tank from becoming pressurized?

I circled the vent cap we are talking about.

EDIT: So my understanding is the FiTech Command Center needs a vent line not a return line like the PowerSurge, so would the FiTech vent line work with the smaller orifice as it is only returning fumes and a limited amount of liquid gas? The PS requires a minimum 1/4" return line back to the tank, so I'm assuming the orifice is smaller than that and that's why you guys are concerned?

EDIT 2: Also was thinking, could I just plug the current vent orifice and weld a bung onto the filler neck and connect my vent line to that instead? Would be easy to do and eliminate the need to empty/cut the gas tank up.

Thanks for the help,

Adam

The sending unit you refer to is located on the lower right side of the tank (as looking to the diagram, which would be the driver's side). If you look at the tank in your car, the sending unit will be near the exhaust pipe in the driver's side. The vent cap will be on top of the tank. You should be able to see the vent line coming from the top of the tank if you look underneath the car, in front of the tank. Sorry, I don't have a picture of the vent cap, but this thread has a picture: https://www.7173mustangs.com/thread-73-gas-tank-fuel-vapor-separator

My suggestion to use a sending unit in place of the vent cap it's just because it fits nicely there. In this case you will be using the sending unit just for the tubing and not for the float. Therefore, you will remove the float and electronics from that sending unit. It's the perfect opportunity to use an old sending unit. Beware with the sending unit from CJPonny. Been there, tried that! I used theirs and leaked right away. I ended up purchasing one from Don from Ohio Mustang. It worked flawlessly.

You are right about the FCC needing just a vent, but I know they had some problems, which I think they already figured out. I like the idea of the PowerSurge better because having a return to the tank helps cool down the gas, plus if something goes wrong, the FCC will "overflow" gas through the vent. I did a lot of research and reading before making my decision.

Yes in regards to the orifice in the vent cap, it's much less than 1/4".

You can connect the vent to the filler neck, but it is much easier to just use a vented gas cap. In my case I used the original cap, but modified it to allow venting.

Taking the tank down is fairly easy and can be done by one person. You then can check the filler neck gasket, filler neck for rust, and sending unit for issues. If your tank is very full, you can try siphoning gasoline through the filler neck, or just remove the fuel hose to the sending unit and drain it through there. If it has a little of gas, you could plug the hose of the sending unit and lower the tank, but it is a lot easier to handle the tank mostly empty. You can lower it onto wood blocks, or onto a garage jack to help bringing it down.

EDIT: PS: don't light a cigarette while doing the job, and keep a fire extinguisher nearby just in case. Oh, also, disconnect the battery.

Last edited by a moderator: