- Joined

- Nov 15, 2016

- Messages

- 652

- Reaction score

- 15

- Location

- Australia

- My Car

- 1972 Mustang Coupe 302 Auto RHD

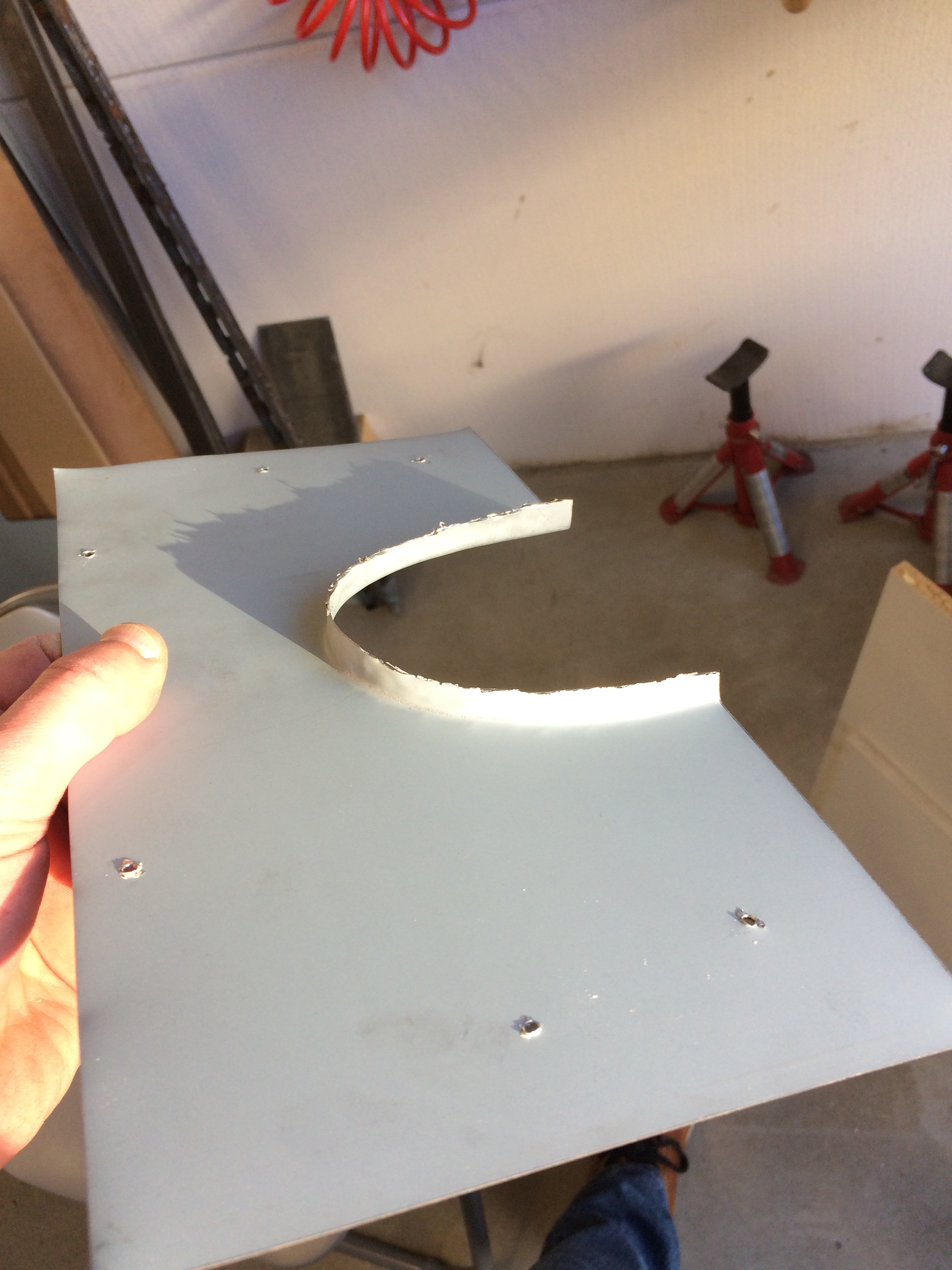

Going well and lucky you had Fabrice there to help you along

Make sure after grinding down your welds to tack up any pin holes

I'm not a good welder but with practice got better at

I am pretty good with a grinder though!

Make sure after grinding down your welds to tack up any pin holes

I'm not a good welder but with practice got better at

I am pretty good with a grinder though!