Alright! I visited professor Fabrice’s secret laboratory out in the whoop whoops and was given the grand tour around his bling bling business. Pretty cool and he even put on a live plating-show for me, I saw the magic in action, awesome!

But also... WOW! That’s what I gotta say about my dipped hood! I picked it up yesterday. As you may remember I gave my hood the vinegar/rustyco treatment last fall. BIG effort but no big results for me as there was still rust on the inside. So I brought it to a dipper (website:

https://www.autobeitserij.nl/en/). Here it was dipped in 3 baths:

1) Paint stripping in caustic soda. This will remove all paint, filler etc. After this step is when most people start to realise what they have started ;-)

2) De-rusting with phosphoric acid. Contrary to hydrochloric acid this leaves no chance for rust to re-appear.

3) Electrolytical coating. First a sinc phosphate coating is put on to protect against rust. Then a coat of primer is put on, all while suspended in liquid. Every possible seam or tube is coated.

Let’s look at some pics:

Nice!

Above is the worst engineered spot in a standard hood, water collects here and... creates a hole.

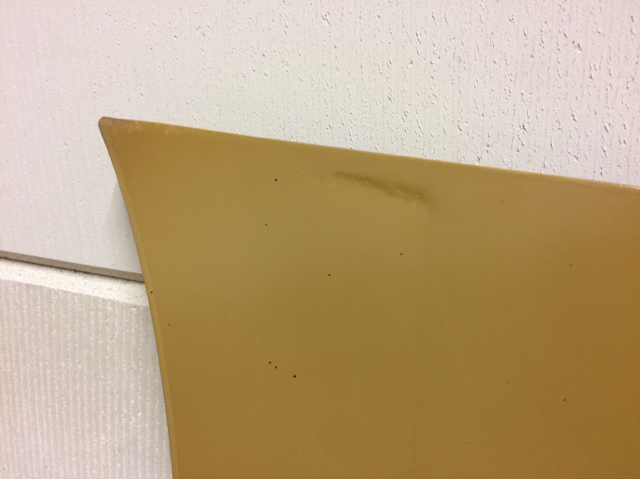

Above shows some pitting but nothing bad.

This hood is now 100% rust free and rust protected for the next 50 years. It can wait in my garage until I need it, in about 10 years ;-)