I've been eyeing up the quickjack lift. Its like the scissor lift but two of them, one on each side of the car. Just waiting/hoping our dollar recovers. I built my shop with 6" reinforced concrete with the plans of doing a 4 post, but once I got all my toys in there I realized it wouldn't really work.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who has a lift at home?

- Thread starter Jeff73Mach1

- Start date

Help Support 7173Mustangs.com:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Aug 14, 2014

- Messages

- 4,637

- Reaction score

- 1,669

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

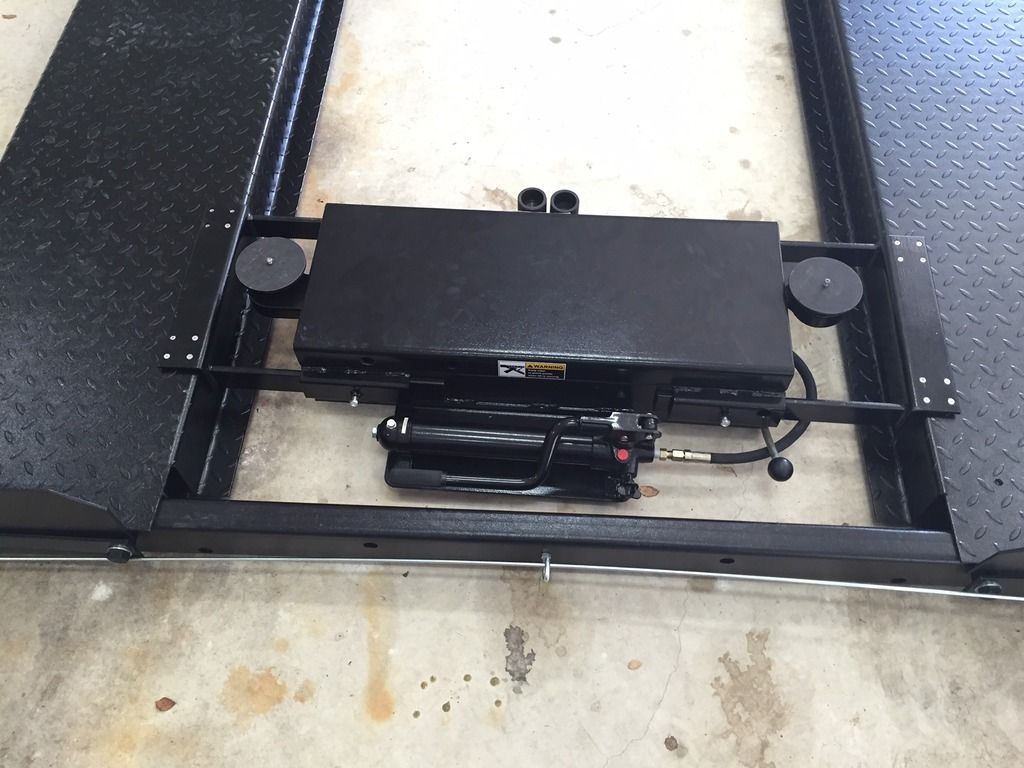

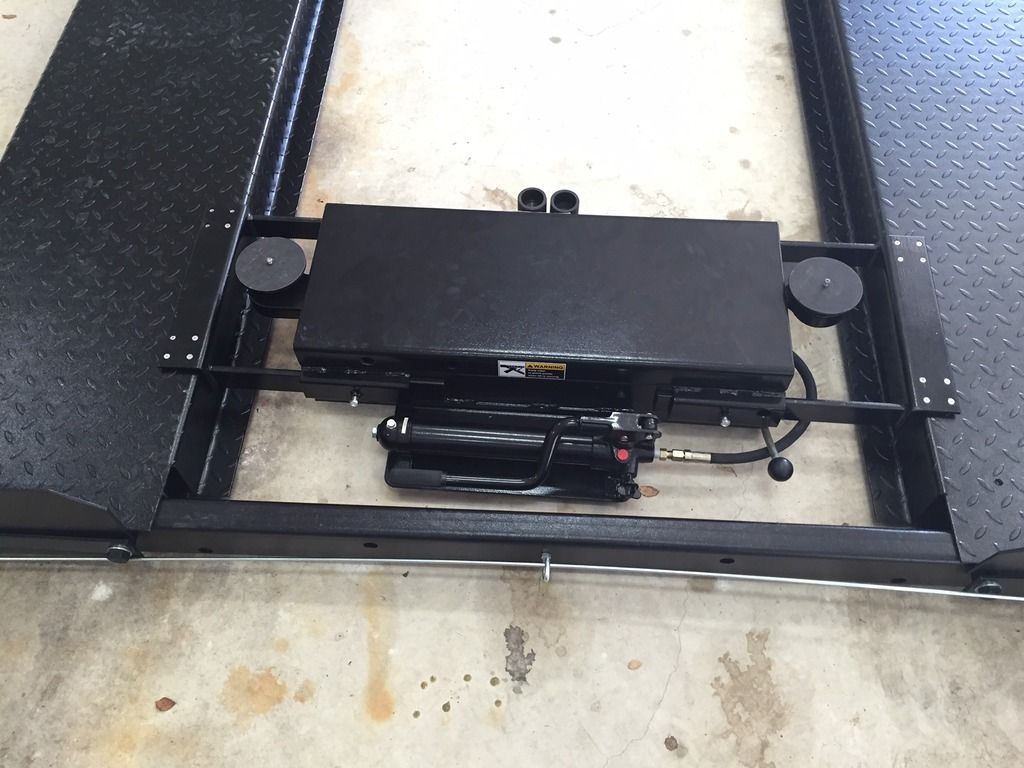

How high is your ceiling?I bought one a few months ago. It is a nine ton four post that also has a jack to lift either end off of the tires if needed. Mine is from The Lift Superstore that has a distributor in nearby San Antonio. I wanted key components USA made and this they offer. The lift was $2800 with delivery and install $600. It includes three sliding/removable drain pans and a stout sliding "pan" that would easily hold a tranny. I swapped some truck tires for the jack ($700 to purchase). I am fortunate to have a large tall garage so no issues there. So far I am more than pleased.

The jack.

- Joined

- Apr 22, 2014

- Messages

- 1,266

- Reaction score

- 12

- Location

- Massachusetts

- My Car

- 1972 Mustang Mach 1

My best friend Dave has one and lets me use it when ever I want so I really don't need to buy one. But I have to say they are really cool to have access to.

- Joined

- Jul 10, 2011

- Messages

- 2,056

- Reaction score

- 606

- Location

- Germany, Southwest, Black Forest

- My Car

- 1973 Ford Mustang Mach 1 T5 Q-Code 4-Speed

NiceHere's my "4 post lift". Total cost about $25 from the scrap bin at Menards.

Thank you, sounds good ::thumb::Tim, So far so good for reliability. I like that when in the lowered position it is only about 5" high, most vehicles can drive right over. Comes with all the lift hard ware including larger adapters for pick up truck type vehicles. Easy to set up also. This is the only scissor type they sell can't remember the model # off hand. I paid $2900 Cdn. Delivered to my nearest truck depot and I picked up from there. So I would think around $2000 US $??? If you haven't got the space or concrete requirements, this is a nice alternative. I researched most of the similar units, decided to pay a few hundred more and get the best of the bunch... Glad I did.Looks good - that would be my decision too because a solid two-post-lift would cost too much room in my garage. Which one did you buy? Any problems with it? How much was it?I went with a BendPak scissor lift. I was too late to address the issue of sufficient concrete strength etc. and I wanted something compact and moveable. This is a good little unit for day to day stuff and of course for my current restoration, will accommodate up to 6000 lbs. There is pretty good room underneath albeit not as good as a 4 post lift. Just bought this last year after spending the previous 37+ years putting jack stands, crawling under... decided that I am not getting any younger... A good purchase for me and the limitations at my current residence.

Thank you,

Tim

I have a 6000 lbs Hanmecson scissors lift. It is almost identical to the bendpack. It is moveable and the car drives over it (technically over 2x10). As you see in the pictures once fully up i place jack stands over the cross as a 3rd safety support just in case.

1971 M-code Mach 1

Looks high enough, cool! Only disatvantage of that type I see will be the fact that you cannot get good access to the middle tunnel, driveshaft or transmission...

P

Pastel Blue

Guest

True, but my thought was, "how often do I really need to get to those areas?" I can get to the front end, oil changes rear diff. etc. Now, as I go to put my vert back together, some of this comes into play, a one time deal and then moving forward no real need. But, this is a decision you have to make before making the purchase.NiceHere's my "4 post lift". Total cost about $25 from the scrap bin at Menards.

::thumb::

Thank you, sounds good ::thumb::Tim, So far so good for reliability. I like that when in the lowered position it is only about 5" high, most vehicles can drive right over. Comes with all the lift hard ware including larger adapters for pick up truck type vehicles. Easy to set up also. This is the only scissor type they sell can't remember the model # off hand. I paid $2900 Cdn. Delivered to my nearest truck depot and I picked up from there. So I would think around $2000 US $??? If you haven't got the space or concrete requirements, this is a nice alternative. I researched most of the similar units, decided to pay a few hundred more and get the best of the bunch... Glad I did.Looks good - that would be my decision too because a solid two-post-lift would cost too much room in my garage. Which one did you buy? Any problems with it? How much was it?

Thank you,

Tim

I have a 6000 lbs Hanmecson scissors lift. It is almost identical to the bendpack. It is moveable and the car drives over it (technically over 2x10). As you see in the pictures once fully up i place jack stands over the cross as a 3rd safety support just in case.

1971 M-code Mach 1

Looks high enough, cool! Only disatvantage of that type I see will be the fact that you cannot get good access to the middle tunnel, driveshaft or transmission...

I have had to make some ramps also, but only because my '13 Boss LS sits so low, damn Ford!

$37.95

$39.95

2015-2024 Ford Mustang Bulge Acorn Lug Nuts & Wheel Locks Kit 14 mm x 1.50 Thread (Black)

West Coast Corvette / Camaro

$29.70

$35.95

Ford Mustang, Mach 1, GT, Shelby, & Boss V-8 (64-73) Haynes Repair Manual

Haynes Repair Manuals

$22.98

JH Design Women's Ford Mustang T-Shirt's in 2 Styles Short Sleeve Crew Neck Shirts (as1, Alpha, l, Regular, Regular, CLG4-black/pink)

Affordable Family Clothing

$34.95

$55.00

The Complete Book of Ford Mustang: Every Model Since 1964-1/2 (Complete Book Series)

Amazon.com

$69.98

JH DESIGN GROUP Men's Ford Mustang Collage Black Zip Up Hoodie Sweatshirt (Large, CLG2-black)

Affordable Family Clothing

$9.00

2016 Hot Wheels Vintage American Muscle 1970 FORD MUSTANG MACH 1 die-cast 4/10

Cards and Bobbles

$13.75

$16.39

Ford Mustang: Trivia & Fun Facts Every Fan Should Know About The Great American Icon!

Amazon.com

$18.77

$24.95

Ford Mustang Pony Racing Stripe 5.0 Muscle Shelby Long Sleeve T-Shirt Front Back Print-Black-Large

Giftware Shop Usa

$119.99

Polished Rocker Panel Sill Plate Molding Kit with Clips Compatible with 1964-1966 Ford Mustang - Authentic Restoration for Classic Car Enthusiasts

Classic 2 Current Fabrication

- Joined

- Jul 10, 2011

- Messages

- 2,056

- Reaction score

- 606

- Location

- Germany, Southwest, Black Forest

- My Car

- 1973 Ford Mustang Mach 1 T5 Q-Code 4-Speed

You're right ::thumb::

- Joined

- Aug 12, 2010

- Messages

- 8,347

- Reaction score

- 740

- Location

- San Angelo, Texas

- My Car

- 1971 Mustang Mach 1

Looks like 12' to me. Might be 14', but the lift posts I believe are 6', and the ceiling 'looks' like it's twice the height of the lift posts.How high is your ceiling?

Just a WAG. :chin:

- Joined

- Jan 7, 2015

- Messages

- 8,032

- Reaction score

- 536

- Location

- Western North Carolina

- My Car

- Multiple Mustangs!

You are limited in the overhead sounds like. I did a lot of research on lifts and the foreign made, most of them, are rated for more than they can actually do. There are videos of them placing steel plates on the lifts and them folding up when it is the advertised capacity. There are lots of videos on the net showing accidents.

I am probably going with a 2 post lift just for ability to get to everything better. Yes you can add extras so you can take the tires off and do stuff but just not as easy to get to things.

Talked with people that use them every day and they say no to 4 post unless you want to stack store cars and you can get the really cheap ones for that.

On the floor mount. They all say you can drill and use drive in concrete bolts. I am not. I am going to do a two stage pour on the garage and when they put the J bolts in for the building uprights they will also put in J bolts with welded re-bar so there is no way they can pull out. Too many videos out there of units folding, bolts pulling out and falling. Not something someone told me but there are videos online.

I have lost the name in my mind of the company in Texas that actually builds their lifts in the U.S. I need to go back in my records and look that up and add to the post. The foreign lifts are made from much less strength steel. Hot rolled steel can vary in yield strength from 20,000 to 100,000 lbs. so there can be huge differences even when they use the same thickness.

I know we all want the least cost we can get but you are going to be under there and your baby will be on it. How the electrical or hydraulics are built can be cheap also. Find a garage that has been using what you are looking at and go talk to someone that has put them to the test. Go look at some of the horror videos online. Some are in big car dealers. The actual testing of lifts are on there and the arms twist and fail when they put the advertised weight on them.

I worked in China for 16 months in a shop and I know how they like to use the minimum they can get by with, bolts, cables, hoses, valves, materials, welding, wiring, motors. They will use the minimum every time not much safety margin if any. Heck our welder did not wear a helmet. I ask one of the guys that could speak English to ask him if his eyes did not hurt and he said no. He would weld 8 hours a day building tables, racks and die stands and only had a piece of cardboard with a hole to look through. The cardboard kept the spatter off his face.

I don't trust them either, lol.

David

I am probably going with a 2 post lift just for ability to get to everything better. Yes you can add extras so you can take the tires off and do stuff but just not as easy to get to things.

Talked with people that use them every day and they say no to 4 post unless you want to stack store cars and you can get the really cheap ones for that.

On the floor mount. They all say you can drill and use drive in concrete bolts. I am not. I am going to do a two stage pour on the garage and when they put the J bolts in for the building uprights they will also put in J bolts with welded re-bar so there is no way they can pull out. Too many videos out there of units folding, bolts pulling out and falling. Not something someone told me but there are videos online.

I have lost the name in my mind of the company in Texas that actually builds their lifts in the U.S. I need to go back in my records and look that up and add to the post. The foreign lifts are made from much less strength steel. Hot rolled steel can vary in yield strength from 20,000 to 100,000 lbs. so there can be huge differences even when they use the same thickness.

I know we all want the least cost we can get but you are going to be under there and your baby will be on it. How the electrical or hydraulics are built can be cheap also. Find a garage that has been using what you are looking at and go talk to someone that has put them to the test. Go look at some of the horror videos online. Some are in big car dealers. The actual testing of lifts are on there and the arms twist and fail when they put the advertised weight on them.

I worked in China for 16 months in a shop and I know how they like to use the minimum they can get by with, bolts, cables, hoses, valves, materials, welding, wiring, motors. They will use the minimum every time not much safety margin if any. Heck our welder did not wear a helmet. I ask one of the guys that could speak English to ask him if his eyes did not hurt and he said no. He would weld 8 hours a day building tables, racks and die stands and only had a piece of cardboard with a hole to look through. The cardboard kept the spatter off his face.

I don't trust them either, lol.

David

- Joined

- Apr 27, 2012

- Messages

- 4,766

- Reaction score

- 108

- Location

- Nashville, Tennessee

- My Car

- 1973 Q code Mach 1

I'm not going to go cheap, the only real question for me is can I fit it in the garage and get full use out of it. If not I'll wait until I have better space to work with.

- Joined

- Jan 7, 2015

- Messages

- 8,032

- Reaction score

- 536

- Location

- Western North Carolina

- My Car

- Multiple Mustangs!

For now you could do what I had for years. My dad dug a pit and laid concrete blocks. You could pull over the pit when you need to work on something under the car and we had plywood cover when not in use. You still have to jack the car if you have 4 post so why not go down and no issue with the ceiling height. Cost is very cheap for the blocks and some concrete for the floor. Just need to be where there are no water issues. He dug mine where I sat on a work roll around instead of standing. He felt sorry for me changing clutches, transmissions and driveshafts with the car sitting on concrete blocks. It never broke and no oil or power, old school.I'm not going to go cheap, the only real question for me is can I fit it in the garage and get full use out of it. If not I'll wait until I have better space to work with.

Here is a link to info to help make a better decision. http://www.gregsmithequipment.com/Which-Lift-Should-I-Buy-2-Post-or-4-Post

Lots of reasons here that I decided to go with 2 post. I never could understand why you would lift the car and then still have to jack the car up to work on it. It looks like storage gain is biggest reason for 4 post. I know several people that actually store their car on jack stands to take the weight off the springs and tires to prevent flat spots and save the springs. A 4 post does nothing for that but a two post would work. If you are going to work on the car the 2 post is the only way in my opinion. You can lift the car to put on a rotisserie or take off rotisserie, no way on four post. If you are doing floor pan work you can lift the jig you have the frame sitting on to get under the car by lifting the jig and car. No way on 4 post. Just way more versatile.

Here is video of them testing one of the Chinese lifts per the U.S. requirements and it totally falls apart. Bends, welds break because of poor design making stress points. When it is tested to the requirements you will see what happens.

http://www.gregsmithequipment.com/When-Is-A-10-000-LB-Lift-Not-A-10-000-LB-Lift

If you are going to pick the car up and look at it and clean it 4 post might be ok but the runways are in the way all the time so working on it sucks.

I am just too practical I guess.

David

Last edited by a moderator:

P

Pastel Blue

Guest

Well, I think most stuff is made offshore, we all know that. The key is to find a final product that utilizes a majority of North American made parts and certification of same once fully assembled. I have also seen and revewed many of these videos David refers to and it was for this reason I chose to stay away from two and four posts knowing that I could not chance the securing of same in my present garage situation.

I previously worked for Underwriters Laboratories ULI (ULC in Canada) and visited many mfrs ensuring their products met applicable UL Standards from mechanical to electrical (you would not believe how some will try to cut corners...). I put this experience to use when i went looking for a lift.

I personally am very aware of offshore made stuff and am very very wary of purchasing same. In the end, strictly from a scissor lift perspective, the BendPak checked off the majority of the "well put together" scissor lift requirements. There is one mfr in upstate NY (can't recall the name at the moment) that makes a scissor lift that might top the Bendpak but the price was double the cost as well. I came close to buying, but the Bendpak swayed me strictly for the purchase price differential and similar build quality. Even still, I could have bought cheaper but the quality was less then impressive. Not a good combination if you have a car in the air.

I am also in full agreement with David, be very wary of lifts that are not fully certified to our expectations here in North America. As for the type of steel and the welding of same, is something that must be looked at personally when buying these pieces as well.

I previously worked for Underwriters Laboratories ULI (ULC in Canada) and visited many mfrs ensuring their products met applicable UL Standards from mechanical to electrical (you would not believe how some will try to cut corners...). I put this experience to use when i went looking for a lift.

I personally am very aware of offshore made stuff and am very very wary of purchasing same. In the end, strictly from a scissor lift perspective, the BendPak checked off the majority of the "well put together" scissor lift requirements. There is one mfr in upstate NY (can't recall the name at the moment) that makes a scissor lift that might top the Bendpak but the price was double the cost as well. I came close to buying, but the Bendpak swayed me strictly for the purchase price differential and similar build quality. Even still, I could have bought cheaper but the quality was less then impressive. Not a good combination if you have a car in the air.

I am also in full agreement with David, be very wary of lifts that are not fully certified to our expectations here in North America. As for the type of steel and the welding of same, is something that must be looked at personally when buying these pieces as well.

- Joined

- Aug 14, 2014

- Messages

- 4,637

- Reaction score

- 1,669

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

My lift looks very well made with good welds. I wont feel comfortable lifting a 6000 lbs car but with the mustang i think there is a safe margin of error. But..... just in case, thats why i place those jack stands at the cross of the scissors. If all fails that could save my life.

The access to the tunnel is limited, but at least there is room to get through the beams. Here are some pictures from below. The front is completely uncovered up to the back of the transmission. You just have to step around the hydraulic cylinders.

1971 M-code Mach 1

The access to the tunnel is limited, but at least there is room to get through the beams. Here are some pictures from below. The front is completely uncovered up to the back of the transmission. You just have to step around the hydraulic cylinders.

1971 M-code Mach 1

- Joined

- Jul 3, 2010

- Messages

- 726

- Reaction score

- 172

- Location

- The OC (California)

- My Car

- 31 Model A Station Wagon “Woody”

69 Mach 1 - 351C

30 Model A Cabriolet

96 Cobra Convertible

I have a Bendpak four post. About 8 years ago I drew up plans and built a home addition which involved rebuilding the garage and new space above it. The design was to accommodate the lift mostly as a storage lift. I've used it to change exhaust, swap a clutch, and some other undercar work, but mostly it is for storage. So far the Bendpak has been great, but I would get a higher lift version if I could do it over. I was worried about hitting the car on the 13' 6" ceiling, but even with a Ford Explorer on the lift it wasn't even close. Another 12" of lift height would have been great.I have been toying with the idea of adding a 4 post lift to my garage.

I worry that my space is just too tight.

For the garage door, mine goes straight up then curves at the high ceiling. This allows me to open the garage door even with a car on it. I wouldn't, and couldn't, have it any other way since it is primarily used as a storage lift, there is always a car on it.

Last edited by a moderator:

EdM

Well-known member

- Joined

- Jun 5, 2014

- Messages

- 600

- Reaction score

- 43

- My Car

- 1973 Mach 1 Q code, a 427 Dart based Windsor, Pro Flo 4, Len Tech AOD, A/C, 12.7:1 steering conversion, SoT coil over and Dakota Digital dash.

Ceiling is 14' 8" and bottom of lift fully up as shown is 6' 4" from grade. Mine also is not bolted down and has roller assemblies for each post that allow it to be easily relocated if desired.How high is your ceiling?I bought one a few months ago. It is a nine ton four post that also has a jack to lift either end off of the tires if needed. Mine is from The Lift Superstore that has a distributor in nearby San Antonio. I wanted key components USA made and this they offer. The lift was $2800 with delivery and install $600. It includes three sliding/removable drain pans and a stout sliding "pan" that would easily hold a tranny. I swapped some truck tires for the jack ($700 to purchase). I am fortunate to have a large tall garage so no issues there. So far I am more than pleased.

The jack.

I was thinking your ceiling was higher than 12'. Mine is almost 12 and I have 6 panels on my garage door. You appear to have 8 So while I probably couldn't clear an SUV and still be under my door I think I two mustangs stacked will fit

So while I probably couldn't clear an SUV and still be under my door I think I two mustangs stacked will fit

Last edited by a moderator:

- Joined

- Aug 14, 2014

- Messages

- 4,637

- Reaction score

- 1,669

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

Edited: sorry, posted in the wrong thread - this post can be deleted.

Last edited by a moderator:

Tony reminded me I should post here. I got one, here it is installed This post helped me immensely in figuring out how high my interior ceiling needed to be

This post helped me immensely in figuring out how high my interior ceiling needed to be

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- Joined

- Dec 23, 2010

- Messages

- 6,624

- Reaction score

- 104

- Location

- Luxembourg / Europe

- My Car

- 1972 Mustang Convertible

Me, me,me!!!!!!

Finally! I've been wanting to post in this thread for so long and it finally happened:

http://www.7173mustangs.com/thread-great-birthday-present

Finally! I've been wanting to post in this thread for so long and it finally happened:

http://www.7173mustangs.com/thread-great-birthday-present

6972boss

Well-known member

- Joined

- Jun 12, 2016

- Messages

- 310

- Reaction score

- 30

- Location

- Gig harbor Wa

- My Car

- 72 sport roof R code waiting to be finished. 67 and 69 shelby's are ahead of it.

Similar threads

- Replies

- 7

- Views

- 1K

- Replies

- 7

- Views

- 2K