- Joined

- Feb 28, 2011

- Messages

- 257

- Reaction score

- 6

- Location

- California

- My Car

- 1971 Mach 1

2000 F250-SD

2001 H-D FLTR

2004 GMC Denali

I didn't receive any response to my previous post so I will try again. I have a 71 Mach 1 351 Cleveland, original C6 car. I pulled the motor, had it rebuilt, and have changed to a toploader transmission. This is my first time installing a motor in a car. I'm sure I've made my share of mistakes up to this point.

The issue I am having is the fitment of the Z bar appears to be too snug, and the alignment looks off. I don't know if its an engine alignment issue, or what it could be. When we installed the engine, the transmission was attached. It went in as one unit. We then bolted the motor mounts to the frame mounts. Right here could be my first issue.

I changed the mounts on the motor. I was not aware that the mounts on the frame could be changed as well.

After tightening the motor mounts, we installed the four speed transmission brace. Installing the transmission brace took a little effort. We had to push and pull the transmission from side to side in order for it to line up with the bracket. This leads me to believe my engine may not be aligned. The headers followed, and installed easily.

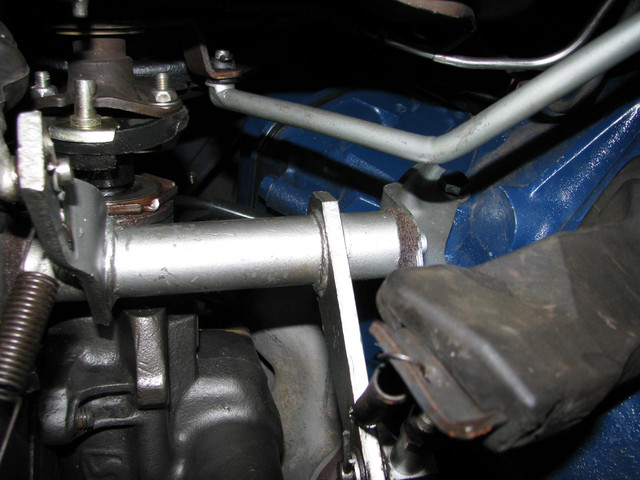

Installing the Z bar was challenging. I don't know what the correct procedure is, but this is how I had to approach it to get it to mount. I first mounted the bracket that goes to the bell housing. I snugged the bolts down but left a slight bit of play in them. This bracket has a 5/8" thick felt washer. I next slid the Z bar onto the ball and nylon bushing. The z bar has the frame mount bracket already installed, as well as a 1/4" felt washer between the z bar and frame bracket. I slid the z bar into place, bolted the bracket to the frame, and tightened down the bracket to the bell housing.

With the Z bar in place, that 5/8" washer that is between the Z bar and bell housing bracket, has been completely smashed. Where the Z bar and felt washer rest against the frame bracket, is not a flush contact, but a slight angle. It also takes some effort to get the z bar to move forward and backward.

I would appreciate it if members could send photos of stock Z bars, and aftermarket Z bars, that illustrates the correct spacing the Z bar should have on each side.

I would also like to see how the felt washer functions. Is it snug fit? Does it float between the bracket and nylon bushing? Does it recess into the Z bar? Are the washers two different sizes.

I've attached a few photos of my parts, and how they look installed. I appreciate any assistance.

#1 Bell housing bracket. Nylon bushing, that has a loose fit itself. 5/8" thick felt washer.

#2 Bell housing bracket, bushing, 5/8" thick felt washer

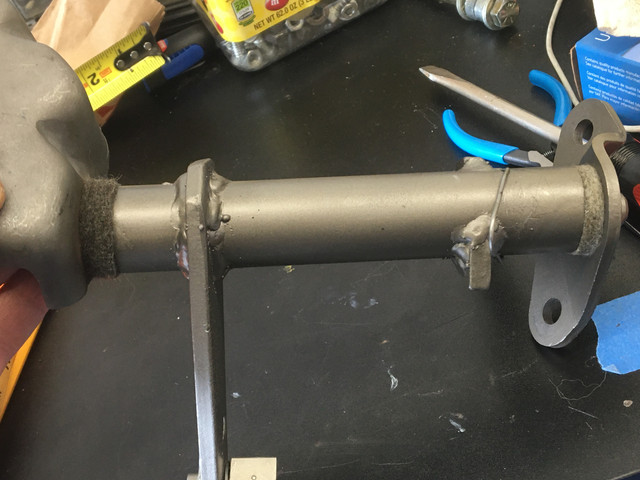

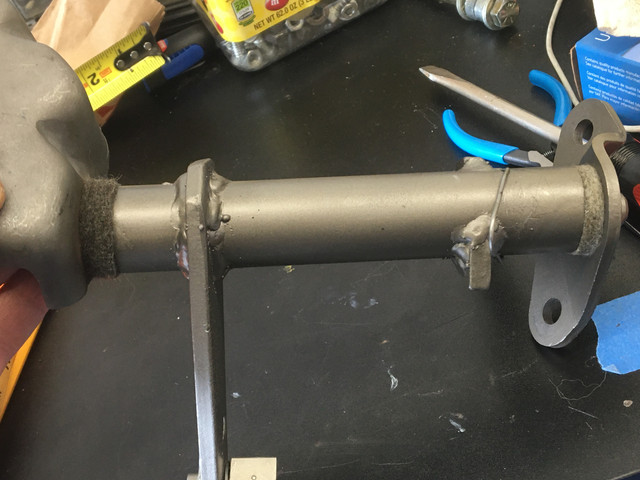

#3 Bracket that mounts to frame, with 1/4" felt washer

#4 Z bar assembly prior to install.

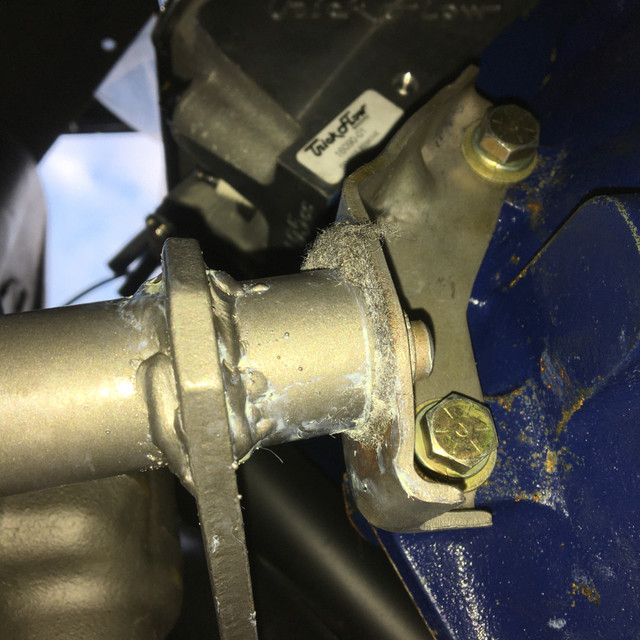

#5 Bracket attached to bell housing. Note, this was the 5/8" thick bracket. Now compressed to almost nothing.

#6 Bracket that attaches to frame of car. Notice how top of z bar is applying pressure against felt washer. The lower part of the z bar has a gap. Also, the washer isn't centered

cranium dice

The issue I am having is the fitment of the Z bar appears to be too snug, and the alignment looks off. I don't know if its an engine alignment issue, or what it could be. When we installed the engine, the transmission was attached. It went in as one unit. We then bolted the motor mounts to the frame mounts. Right here could be my first issue.

I changed the mounts on the motor. I was not aware that the mounts on the frame could be changed as well.

After tightening the motor mounts, we installed the four speed transmission brace. Installing the transmission brace took a little effort. We had to push and pull the transmission from side to side in order for it to line up with the bracket. This leads me to believe my engine may not be aligned. The headers followed, and installed easily.

Installing the Z bar was challenging. I don't know what the correct procedure is, but this is how I had to approach it to get it to mount. I first mounted the bracket that goes to the bell housing. I snugged the bolts down but left a slight bit of play in them. This bracket has a 5/8" thick felt washer. I next slid the Z bar onto the ball and nylon bushing. The z bar has the frame mount bracket already installed, as well as a 1/4" felt washer between the z bar and frame bracket. I slid the z bar into place, bolted the bracket to the frame, and tightened down the bracket to the bell housing.

With the Z bar in place, that 5/8" washer that is between the Z bar and bell housing bracket, has been completely smashed. Where the Z bar and felt washer rest against the frame bracket, is not a flush contact, but a slight angle. It also takes some effort to get the z bar to move forward and backward.

I would appreciate it if members could send photos of stock Z bars, and aftermarket Z bars, that illustrates the correct spacing the Z bar should have on each side.

I would also like to see how the felt washer functions. Is it snug fit? Does it float between the bracket and nylon bushing? Does it recess into the Z bar? Are the washers two different sizes.

I've attached a few photos of my parts, and how they look installed. I appreciate any assistance.

#1 Bell housing bracket. Nylon bushing, that has a loose fit itself. 5/8" thick felt washer.

#2 Bell housing bracket, bushing, 5/8" thick felt washer

#3 Bracket that mounts to frame, with 1/4" felt washer

#4 Z bar assembly prior to install.

#5 Bracket attached to bell housing. Note, this was the 5/8" thick bracket. Now compressed to almost nothing.

#6 Bracket that attaches to frame of car. Notice how top of z bar is applying pressure against felt washer. The lower part of the z bar has a gap. Also, the washer isn't centered

cranium dice