- Joined

- Jan 7, 2015

- Messages

- 8,032

- Reaction score

- 530

- Location

- Western North Carolina

- My Car

- Multiple Mustangs!

I bought this 1972 Q code automatic convertible off of craigslist close to 5 years ago. Time flies when you are having fun.

The PO had $16,000 in receipts for parts and work done. He took the body to Chem Strip in N.C. and dip stripped it. That is the place my friend uses to cars he has dipped. I got the car and a pile of extra parts for $5,500 even a Ford ram air system.

It has been at least 10 years since in the tanks and there are no signs of any bleed from any of the seams.

He had it back to a rolling chassis using all Ford components. I will have to take some back apart he had already installed side windows and was just in primer. Instead of just adding weight to the door to simulate the finished weight he was putting it together. I do have a power window set up for this year and might go with it. Not a true to Marti report build for sure.

The car is pretty well optioned Marti attached. I did buy another crashed 1972 vert that had the same ginger interior that is perfect. So it will have a factory interior.

All Q codes in 72 got a NASA hood but this one did not get black out it was Gold Glow in color. I am going to do a NASA hood without black and one with black and hood locks.

I also have a set of the Decor Group trim and think I will add so it is correct with side stripes that it did not have.

It is a pretty good bet this will be my last build so I am going to make it my last hot rod. Going to get Ben Barnes a local NASCAR engine builder that is retired but still helps the little guys out. He can dyno the engine and he knows how to build them He just did a 289 for a friend with stock heads, pump gas and just a roller cam and it put out over 340 HP on the dyno.

It will probably upset some but since this is my last hot rod I am going with at least a 6 point roll cage and probably an 8 point so I can run SCCA and track days events with it. No other way to really enjoy the car. If they catch you street racing here the can and will take your car.

So I got it out and going to bolt up to the rotisserie for sanding and paint. Hope I can get done this year. Will probably get my friend to paint since I have no experience with the new stuff. I will wipe down with prep solvent and dust on the 3-M sanding guide coat and see how it looks.

I am going to do my own roll cage and frame connectors and use steel that is about twice as strong as current vendor supplied products. Why not make it better. I have the tube bender up to 3" and love to do fab.

I am thinking I will at least go with a 5 speed I do not have the money to go too crazy. He had already built the engine for the car but not knowing what he did I do not trust. He had the C-6 built also adding the extra clutches. I do have a standard 4 bolt block and the 1970 CC chamber heads but might go for Australian heads.

I have too keep my garden and home going so not a full time job for sure.

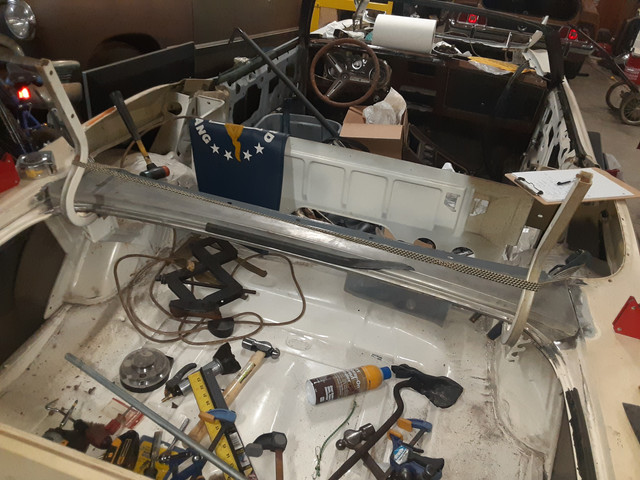

So this is what I pulled out today. Lots of things I have to take back out he had the dash back but it will come out.

I cut the filler panel out of the crashed 72 vert to go into this one. It was from Michigan but was totally rust free. I ran through the molasses tank and coated inside with POR. I will weld that in before going on the rotisserie.

2F03Q178729_dlxrpt.pdf

The PO had $16,000 in receipts for parts and work done. He took the body to Chem Strip in N.C. and dip stripped it. That is the place my friend uses to cars he has dipped. I got the car and a pile of extra parts for $5,500 even a Ford ram air system.

It has been at least 10 years since in the tanks and there are no signs of any bleed from any of the seams.

He had it back to a rolling chassis using all Ford components. I will have to take some back apart he had already installed side windows and was just in primer. Instead of just adding weight to the door to simulate the finished weight he was putting it together. I do have a power window set up for this year and might go with it. Not a true to Marti report build for sure.

The car is pretty well optioned Marti attached. I did buy another crashed 1972 vert that had the same ginger interior that is perfect. So it will have a factory interior.

All Q codes in 72 got a NASA hood but this one did not get black out it was Gold Glow in color. I am going to do a NASA hood without black and one with black and hood locks.

I also have a set of the Decor Group trim and think I will add so it is correct with side stripes that it did not have.

It is a pretty good bet this will be my last build so I am going to make it my last hot rod. Going to get Ben Barnes a local NASCAR engine builder that is retired but still helps the little guys out. He can dyno the engine and he knows how to build them He just did a 289 for a friend with stock heads, pump gas and just a roller cam and it put out over 340 HP on the dyno.

It will probably upset some but since this is my last hot rod I am going with at least a 6 point roll cage and probably an 8 point so I can run SCCA and track days events with it. No other way to really enjoy the car. If they catch you street racing here the can and will take your car.

So I got it out and going to bolt up to the rotisserie for sanding and paint. Hope I can get done this year. Will probably get my friend to paint since I have no experience with the new stuff. I will wipe down with prep solvent and dust on the 3-M sanding guide coat and see how it looks.

I am going to do my own roll cage and frame connectors and use steel that is about twice as strong as current vendor supplied products. Why not make it better. I have the tube bender up to 3" and love to do fab.

I am thinking I will at least go with a 5 speed I do not have the money to go too crazy. He had already built the engine for the car but not knowing what he did I do not trust. He had the C-6 built also adding the extra clutches. I do have a standard 4 bolt block and the 1970 CC chamber heads but might go for Australian heads.

I have too keep my garden and home going so not a full time job for sure.

So this is what I pulled out today. Lots of things I have to take back out he had the dash back but it will come out.

I cut the filler panel out of the crashed 72 vert to go into this one. It was from Michigan but was totally rust free. I ran through the molasses tank and coated inside with POR. I will weld that in before going on the rotisserie.

2F03Q178729_dlxrpt.pdf

Attachments

Last edited by a moderator: