Paul of MO

Well-known member

- Joined

- Jul 2, 2011

- Messages

- 638

- Reaction score

- 16

- Location

- Land of old Geezers

- My Car

- 71 M Code Convert - Barn find

73 H Code Convert - Field find

73 H code - Latest Project

The picture of the cam bearing that was posted is a 400M not a 351C - I can tell by the casting line. And yes it is set to deep into the block.

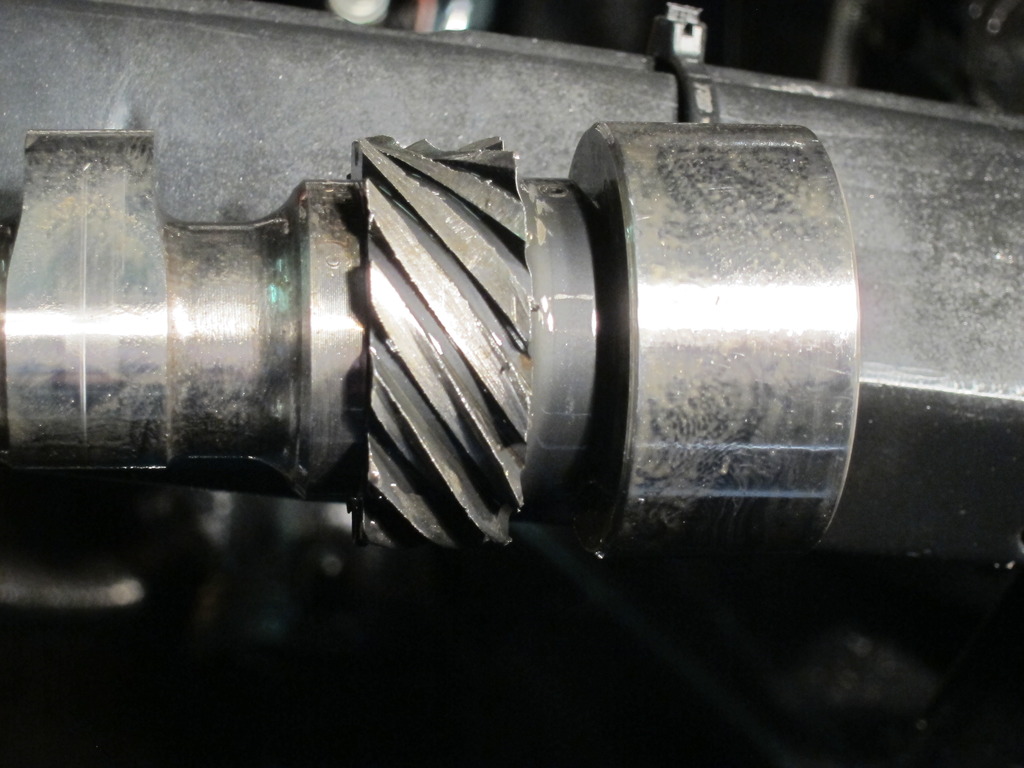

Here is a better picture showing how close to thrust face of the block the front cam bearing is in a 351C.

Now in real life will this cause a problem? Not really. As long as all of the flat area in the block is covered by the bearing then you are good. If the bearing is farther back into the block exposing some of the flat area then yes - more of that oil passage would be exposed and that would not be good.

For our engineers (even the ones in denial) - if the bearing protruded farther forward and stuck out over the bevel (like in my picture) would more of that oil hole actually be covered or would it just be shrouded a little bit?

I think Ford just wanted to make sure you had it in far enough not to interfere with the thrust plate so they gave a specification to accomplish this goal.

The only real important thing is to have the bearing lined up with the oil passages for the mains and for the rockers. To shallow or to deep or clocked wrong and life will not be good.

As far as cam bearings go they typically can last though 3 or 4 or 10 full life spans of an engine. If there is no signs of damage or wear I typically did not replace them.

351C cam bearings are honed after they are installed and replacements are most often to tight. Again not a big deal - things will clearance themselves most of the time.

I had a used cam that we cut a deep grove in the bearing journals then we would coat them with a very fine cutting compound then spin it with a drill to clearance the new bearings. Seemed to work OK. The new cams went from being almost impossible to turn by hand to spinning like they had been buttered.

I have built and run many 351C's that the cam started off tight without any problems. We only used the tool for the ones that were really stiff.

Like I say the most important thing is to have fun!

(Do not drill a hole in your galley plug - it will cause a leak)

(The photo of the galley plug is a 351M not a 351C not that it matters)

- Paul of MO

Here is a better picture showing how close to thrust face of the block the front cam bearing is in a 351C.

Now in real life will this cause a problem? Not really. As long as all of the flat area in the block is covered by the bearing then you are good. If the bearing is farther back into the block exposing some of the flat area then yes - more of that oil passage would be exposed and that would not be good.

For our engineers (even the ones in denial) - if the bearing protruded farther forward and stuck out over the bevel (like in my picture) would more of that oil hole actually be covered or would it just be shrouded a little bit?

I think Ford just wanted to make sure you had it in far enough not to interfere with the thrust plate so they gave a specification to accomplish this goal.

The only real important thing is to have the bearing lined up with the oil passages for the mains and for the rockers. To shallow or to deep or clocked wrong and life will not be good.

As far as cam bearings go they typically can last though 3 or 4 or 10 full life spans of an engine. If there is no signs of damage or wear I typically did not replace them.

351C cam bearings are honed after they are installed and replacements are most often to tight. Again not a big deal - things will clearance themselves most of the time.

I had a used cam that we cut a deep grove in the bearing journals then we would coat them with a very fine cutting compound then spin it with a drill to clearance the new bearings. Seemed to work OK. The new cams went from being almost impossible to turn by hand to spinning like they had been buttered.

I have built and run many 351C's that the cam started off tight without any problems. We only used the tool for the ones that were really stiff.

Like I say the most important thing is to have fun!

(Do not drill a hole in your galley plug - it will cause a leak)

(The photo of the galley plug is a 351M not a 351C not that it matters)

- Paul of MO

Last edited by a moderator: