- Joined

- Mar 30, 2017

- Messages

- 2,338

- Reaction score

- 822

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

Finally got my gasket set, so was back on the 429...

I'm totally not familiar with this engine (and did not open it either). While busy came across some weird stuffs...

So got 5 questions, hoping someone can help me...

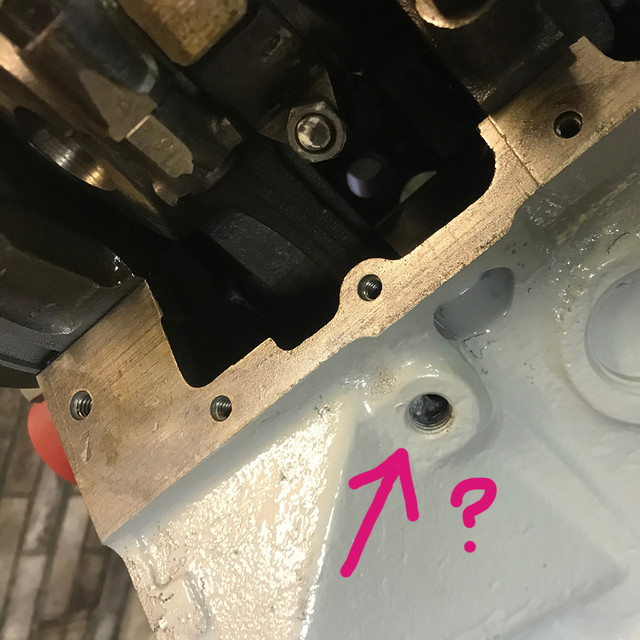

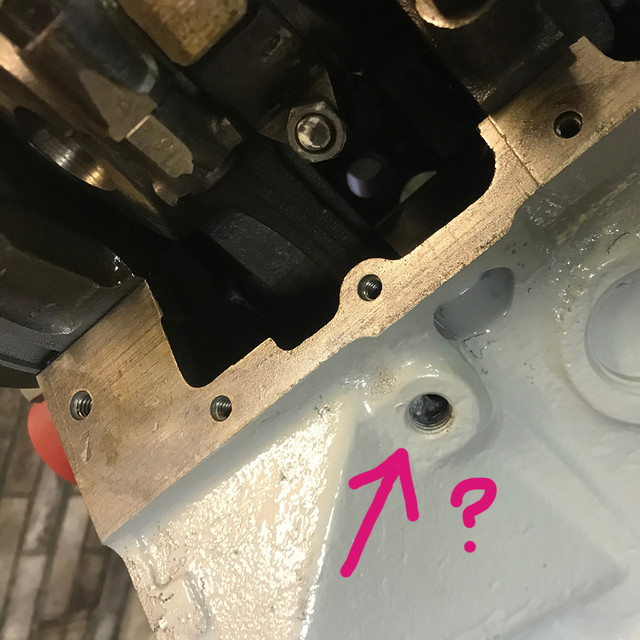

#1

there is a hole with athread on the block, (was busy placing the oil pump back, so engine is upside down)

its on the rear on driver side. If i blow, the air goes out somewhere. without restrictions. Is it part of the cast and do I need a plug or something?

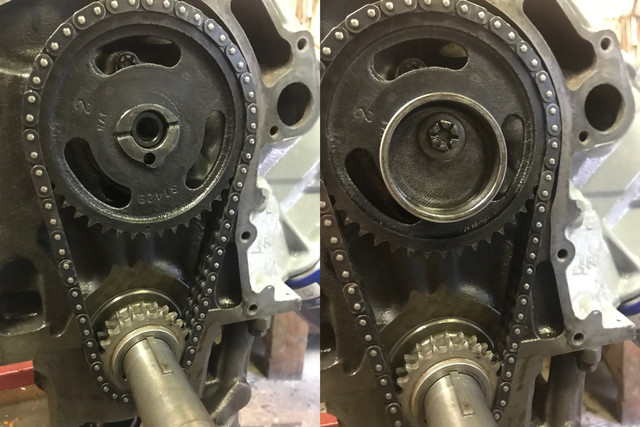

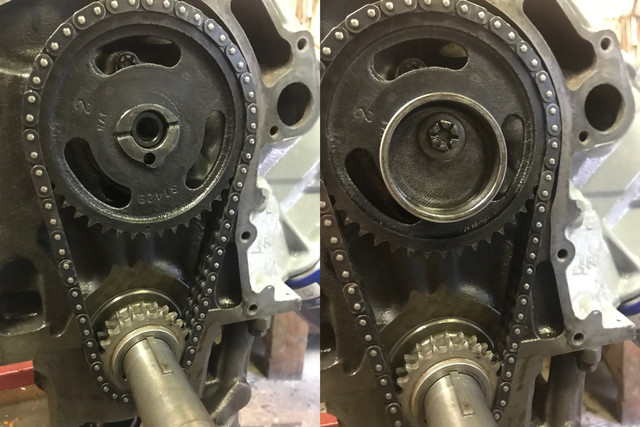

#2

On the doc I have there is nothing to be seen on this, except i need align the dot of the bigger gear to the 0 mark on the lower gear

of the timing chain. So far so good, but then, got that excentric thingy for the fuel pump, that is if i follow the drawings, bolted on with the cam bolt.

but there is nothing that prevents it to rotate if by some reason the bolt would come loose. Is this normal or the propper way to add that thing?

As I will place an EFI later on, I don't need it but thought, may something hapend, I may like be able to put a carb without opening the engine again.

So question is, is it really the way it should be placed?

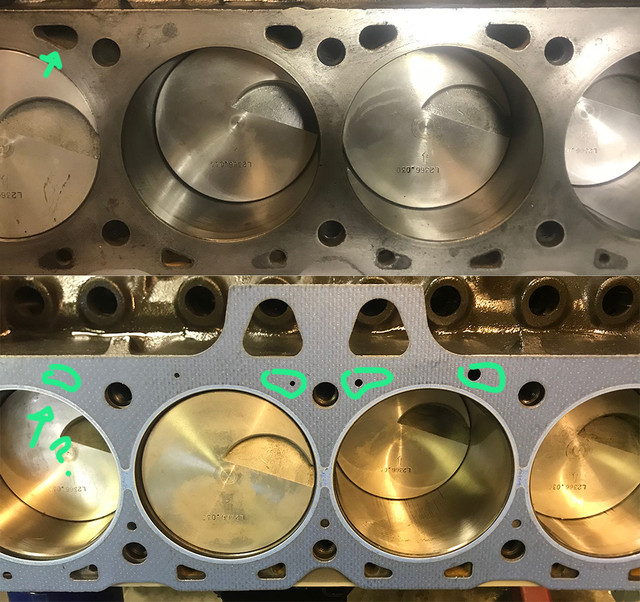

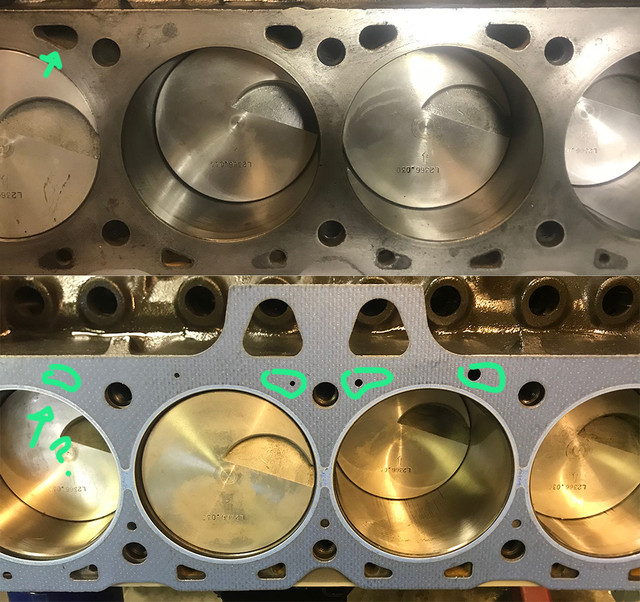

#3

The engine came with buckets of parts, nuts, bolts and gaskets. As I was missing the intake, the oil pan and exhaust ordered a full set.

So got this Felpro set, also with head gaskets. I've open the other pack i was already having and compared them.

The brand is Corteco, and they have reinforcement in metal that the flepro are not having (felpro has just a ring in metal around cyl shapes)

Which one shoudl I use? they seams be as thick. Wondering if the Corteco, with the extra metal would go "flat" as the flepros..

#4

I recall from a long time ago, that i was told, I should pay attention I get the propper gaskets for a CJ. So while inspecting, i saw water passages are

either closed or very restricted. Both sets have same holes. On the heads the water passage do match. So question is, is it normal, or should I open them?

Its weird to have water passages from block to heads and have these closed by a gasket...

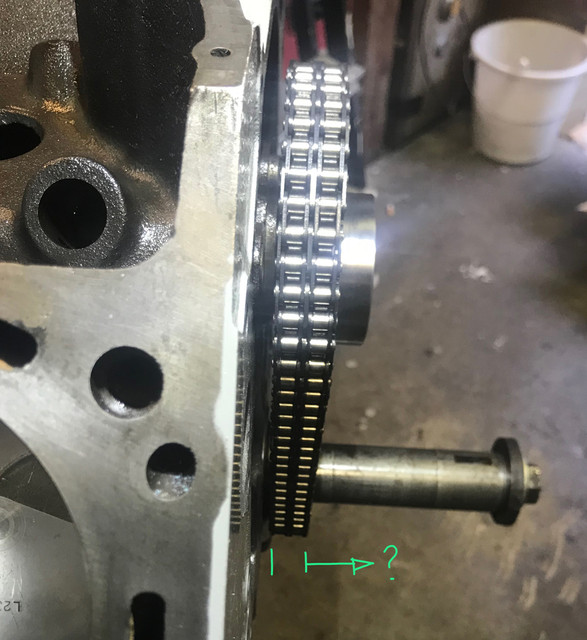

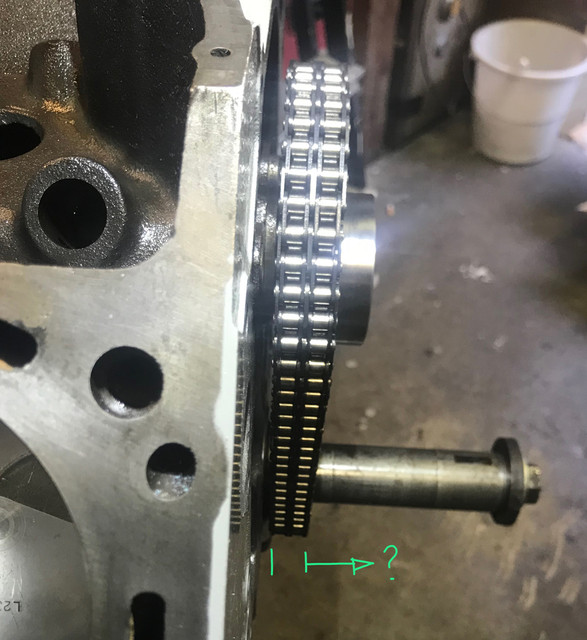

#5

This one worries me most. Installed the new cam with tons of assembly lub from Lucas. So far so good, but when I've placed back the chain

I saw the cam needed go deeper. No big deal, except, I see the lobes ar enot matching the lifters guides.

Added one lifter and its clear they are not aligned.

On this pict, the chain is aligned with the lower gear, so as the cam can float, I wonder if I need to move the lower gear toward the front of the engine?

The lower gear was still on the crankshaft. Or is there some kind of spacer I need somewhere?

Also if I need to move the lower gear how do I do this? There is a, say 2 inches, long piece of metal on the crankshaft, I tried to tap it out, but I would not move. Do i need tap it with greater force and then only the gear would then came out, or do i need extract the gear a bit and it would be guided by this little metal part? From what I can see on lobes, it looks like i would need to have the cam bit forward by say a 1/4 of an inch, 5 or 6mm.

I could provide more picts if required... behind the top gear, there is only a plate with 2 bolts that holds the cam, and I have tried rotate the engine while pulling a bit and the cam would then be aligned, of course, the lower gear is then no longer aligned... so it would need go forward the engine. I wonder then, if there should be some kind of spacer behind...

If someone have clues, some light would be very welcome...

I'm totally not familiar with this engine (and did not open it either). While busy came across some weird stuffs...

So got 5 questions, hoping someone can help me...

#1

there is a hole with athread on the block, (was busy placing the oil pump back, so engine is upside down)

its on the rear on driver side. If i blow, the air goes out somewhere. without restrictions. Is it part of the cast and do I need a plug or something?

#2

On the doc I have there is nothing to be seen on this, except i need align the dot of the bigger gear to the 0 mark on the lower gear

of the timing chain. So far so good, but then, got that excentric thingy for the fuel pump, that is if i follow the drawings, bolted on with the cam bolt.

but there is nothing that prevents it to rotate if by some reason the bolt would come loose. Is this normal or the propper way to add that thing?

As I will place an EFI later on, I don't need it but thought, may something hapend, I may like be able to put a carb without opening the engine again.

So question is, is it really the way it should be placed?

#3

The engine came with buckets of parts, nuts, bolts and gaskets. As I was missing the intake, the oil pan and exhaust ordered a full set.

So got this Felpro set, also with head gaskets. I've open the other pack i was already having and compared them.

The brand is Corteco, and they have reinforcement in metal that the flepro are not having (felpro has just a ring in metal around cyl shapes)

Which one shoudl I use? they seams be as thick. Wondering if the Corteco, with the extra metal would go "flat" as the flepros..

#4

I recall from a long time ago, that i was told, I should pay attention I get the propper gaskets for a CJ. So while inspecting, i saw water passages are

either closed or very restricted. Both sets have same holes. On the heads the water passage do match. So question is, is it normal, or should I open them?

Its weird to have water passages from block to heads and have these closed by a gasket...

#5

This one worries me most. Installed the new cam with tons of assembly lub from Lucas. So far so good, but when I've placed back the chain

I saw the cam needed go deeper. No big deal, except, I see the lobes ar enot matching the lifters guides.

Added one lifter and its clear they are not aligned.

On this pict, the chain is aligned with the lower gear, so as the cam can float, I wonder if I need to move the lower gear toward the front of the engine?

The lower gear was still on the crankshaft. Or is there some kind of spacer I need somewhere?

Also if I need to move the lower gear how do I do this? There is a, say 2 inches, long piece of metal on the crankshaft, I tried to tap it out, but I would not move. Do i need tap it with greater force and then only the gear would then came out, or do i need extract the gear a bit and it would be guided by this little metal part? From what I can see on lobes, it looks like i would need to have the cam bit forward by say a 1/4 of an inch, 5 or 6mm.

I could provide more picts if required... behind the top gear, there is only a plate with 2 bolts that holds the cam, and I have tried rotate the engine while pulling a bit and the cam would then be aligned, of course, the lower gear is then no longer aligned... so it would need go forward the engine. I wonder then, if there should be some kind of spacer behind...

If someone have clues, some light would be very welcome...