scacer1,

How old is that carburetor? I have had Holley's tuned and tuned just to discover that they had internal cracks causing vacuum leaks. If your budge allows, chunk the Holley and get you a FiTech system. I have the FiTech Go 400 and just love it!

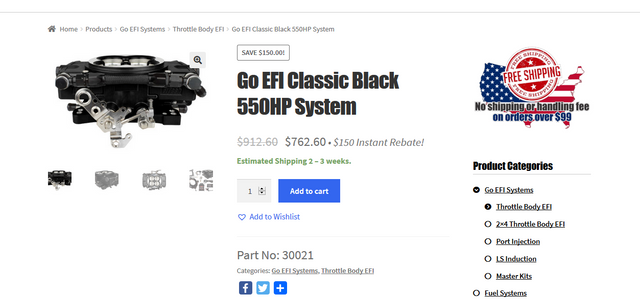

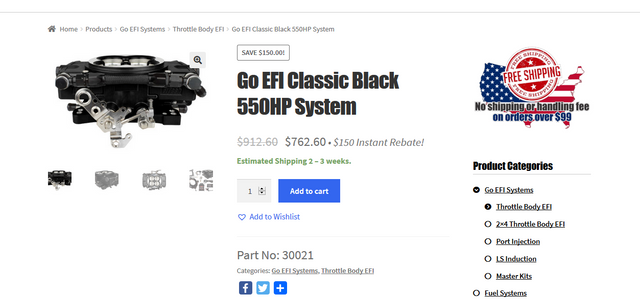

https://fitechefi.com/products/30021/

Brand New out of the box. The Holley Ultra series uses billet aluminum metering blocks so I don't think that is the problem (Although there could be an internal crack in the main body). Also I put a different carb on it and it is still fouling the plugs. That is why I am thinking that this is a reversion problem. I would rather try to get this tuned than to chuck a brand new carburetor, but it may come to that if I cant get this tuned right.