- Joined

- Nov 15, 2010

- Messages

- 932

- Reaction score

- 18

- Location

- annapolis-maryland

- My Car

- 73 Mustang Convertable

Hi All,

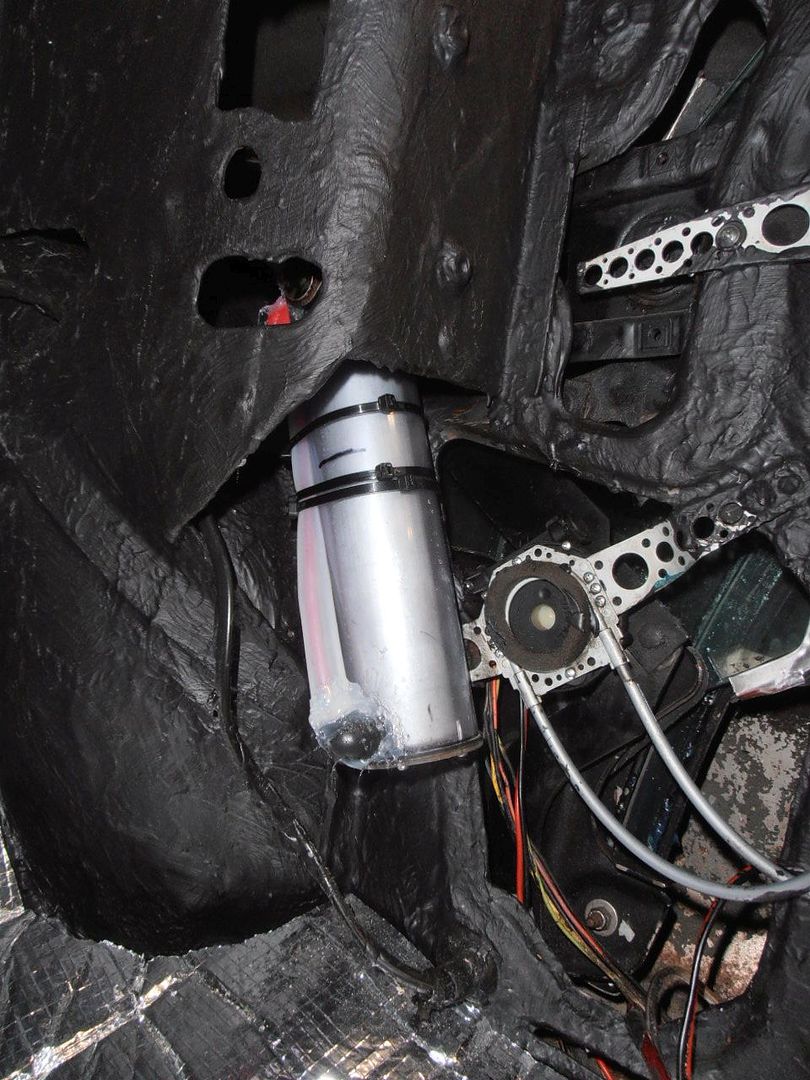

I am in the process of replacing my convertible pump and can't remember which side of the pump raises the top and which side lowers it. 50/50 odds, and I know I will put it together backwards and have to switch couplings after I have everything charged with fluid.

Does the hose connection on the same side as the electric wires raise or lower the top?

TIA

mud

I am in the process of replacing my convertible pump and can't remember which side of the pump raises the top and which side lowers it. 50/50 odds, and I know I will put it together backwards and have to switch couplings after I have everything charged with fluid.

Does the hose connection on the same side as the electric wires raise or lower the top?

TIA

mud

Last edited by a moderator: