You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Danish Mustang “Pro-Touring" project - Creator 526

- Thread starter protouringstang73

- Start date

Help Support 7173Mustangs.com:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 6, 2015

- Messages

- 4,448

- Reaction score

- 279

- Location

- Iowa

- My Car

- 1973 Mustang Grande 351C 2v

Nice work!

And now I have moved on to the firewall, my plan here is to make a smooth and clean firewall, yeah my plan is actually to smooth and clean the entire engine bay and make it look nice.. but today it was the firewall I worked on, I made the panel the way I wanted it, made it fit into the place where I cut the old one out, attacted it with some weldings and tomorrow I will finish it.. here are some pictures of my work today

I am allmost done with the enginebay, just waiting for a new motor for the compressor so I can make it work again and blast the enginebay with sand and get it primed!

While waiting on that I started my third brakelight project that will be placed on the roof. It will be build from fiberglass and foam as my 2 splitted rear spoiler are. The pictures shows as far as I am in the process right now, I hope you can see my idea. I cant wait to see how this will end up finished, I’m looking forward to it, I just love building custom parts, stay tuned

While waiting on that I started my third brakelight project that will be placed on the roof. It will be build from fiberglass and foam as my 2 splitted rear spoiler are. The pictures shows as far as I am in the process right now, I hope you can see my idea. I cant wait to see how this will end up finished, I’m looking forward to it, I just love building custom parts, stay tuned

Sorry guys, the pictures above did upload in a wrong direction, hope you can figure it out where it starts and ends

Last edited by a moderator:

$29.70

Ford Mustang, Mach 1, GT, Shelby, & Boss V-8 (64-73) Haynes Repair Manual

Haynes Repair Manuals

$13.75

$16.39

Ford Mustang: Trivia & Fun Facts Every Fan Should Know About The Great American Icon!

Amazon.com

$35.44

$39.95

2015-2024 Ford Mustang Bulge Acorn Lug Nuts & Wheel Locks Kit 14 mm x 1.50 Thread (Black)

West Coast Corvette / Camaro

$9.00

2016 Hot Wheels Vintage American Muscle 1970 FORD MUSTANG MACH 1 die-cast 4/10

Cards and Bobbles

$24.95

Ford Mustang Pony Racing Stripe 5.0 Muscle Shelby Long Sleeve T-Shirt Front Back Print-Black-Large

Giftware Shop Usa

$64.98

JH DESIGN GROUP Men's Ford Mustang Collage Black Zip Up Hoodie Sweatshirt (Large, CLG2-black)

Affordable Family Clothing

$40.13

$55.00

The Complete Book of Ford Mustang: Every Model Since 1964-1/2 (Complete Book Series)

Amazon.com

$99.99

Polished Rocker Panel Sill Plate Molding Kit with Clips Compatible with 1964-1966 Ford Mustang - Authentic Restoration for Classic Car Enthusiasts

Classic 2 Current Fabrication

$32.29

$60.00

Shelby American 60 Years of High Performance: The Stories Behind the Cobra, Daytona, Mustang GT350 and GT500, Ford GT40 and More

Greenpine_Books

$39.99

Lucky Ride Ford Hoodie Legend Lives Mustang Pony (Pocket) Full Zip Sweatshirt, Red, Medium

Giftware Shop Usa

$18.99

$19.89

Checkered Flag Men's Ford Mustang Cap Tri-Bar Pony Logo Adjustable Black Hat

BS STORE LLC

Made some more adjusments to my third brakelight panel today, damn I like it so far! I also started sandblasting the doors, there is something satisfying about blasting a 46 year old door there is in allmost perfect condition! Will continue with the enginebay and inside of the car tomorrow if the weather is good

- Joined

- Jul 11, 2014

- Messages

- 909

- Reaction score

- 21

- Location

- Toronto, Canada

- My Car

- I am Currently restomoding a 71 Fastback. I designed a wide-body kit for the rear of the car and a more aggressive front nose. The back of the car is 6 inches wider than stock to accommodate the 315 on 12 inch rims.

Car is coming along beautifully buddy.

- Joined

- Apr 27, 2012

- Messages

- 4,766

- Reaction score

- 107

- Location

- Nashville, Tennessee

- My Car

- 1973 Q code Mach 1

No doubt the work on the 3rd brake light is of high quality crafstmanship, but why not just flip it over and put it inside the car and mount it flush to the glass?

- Joined

- Mar 30, 2017

- Messages

- 2,400

- Reaction score

- 892

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

Wow, being busy these days, missed your updates. Some impressive progress!

One little detail:

The third light resin has bubbles. These can (and they will soon or later) expand when exposed to sun light/heat and they'll ruin your surface.

When you'll sand it straight, you might also pop one of them open or end up with a thin layer on top of one.

Considering the enormous amount of work you put on the car and the love involved. Personally I'd consider it as a buck,

and press one out of a 1mm alu sheet instead using this one as a ref.

One little detail:

The third light resin has bubbles. These can (and they will soon or later) expand when exposed to sun light/heat and they'll ruin your surface.

When you'll sand it straight, you might also pop one of them open or end up with a thin layer on top of one.

Considering the enormous amount of work you put on the car and the love involved. Personally I'd consider it as a buck,

and press one out of a 1mm alu sheet instead using this one as a ref.

Car is coming along beautifully buddy.

thanks a lot buddy! But damn it’s a slow process, would really like too see a more complete car soon!

yeah it takes a lot of time to create things like that from the bottom up, but it’s worth it in the end, I like to make things that you cant buy anywhereNo doubt the work on the 3rd brake light is of high quality crafstmanship, but why not just flip it over and put it inside the car and mount it flush to the glass?

thanks man! I actually think it’s non impressive progress, damn it’s a slow process!Wow, being busy these days, missed your updates. Some impressive progress!

One little detail:

The third light resin has bubbles. These can (and they will soon or later) expand when exposed to sun light/heat and they'll ruin your surface.

When you'll sand it straight, you might also pop one of them open or end up with a thin layer on top of one.

Considering the enormous amount of work you put on the car and the love involved. Personally I'd consider it as a buck,

and press one out of a 1mm alu sheet instead using this one as a ref.

A big thanks for the great advices, I really appreciate that! As for the bubbles, are you sure that it’s not just the bubbles them selves that are in the foam you are thinking about? You can see thru the resin and fiberglass and see the foam underneith. But I will take your advice to me and look close for more bubbles. Thanks again. The alu sheet was also a nice idea. But I actually like to work with this fiberglass, you can also change something if it isnt as you want it

- Joined

- Mar 30, 2017

- Messages

- 2,400

- Reaction score

- 892

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

As I have great respect for those daring making their own parts, it's hard to write a remark as I did without hurting feelings. So really, I'm glad you see the constructive side of it.I really appreciate that! As for the bubbles, are you sure that it’s not just the bubbles them selves that are in the foam you are thinking about? The alu sheet was also a nice idea. But I actually like to work with this fiberglass, you can also change something if it isnt as you want it

When I've moved in this country a zillion years ago and started at zero. I've worked in a polyester company, making canoes and all kind of composites parts as a side activity while learning that weird language that is Dutch to find a job.

All that to say that I know a bit what trapped air can do. Hence why lots of parts were cured under vacuum. I let u decide if the bubbles are real or not. Just warning you in case they are real and near of top surface.

About the aluminium sheet, I did not extend, but while you could make it out of aluminum, I was thinking of pressing the shape to make a mould, you'd then have a perfect curve and smooth surface and then using gelcoat first, then resin no worries for bubbles and a whole lot less work to get your part as you want it.

Using plywood/mdf bigger than your sheet and have bolts do the hard work. Depending on shapes, the art is to find the ideal space between the two.

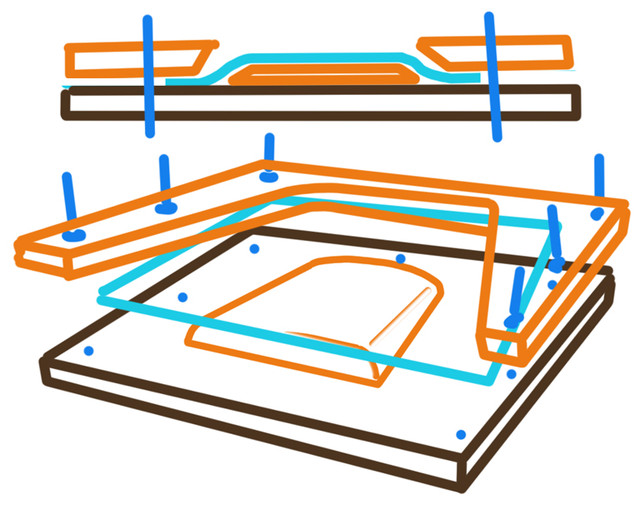

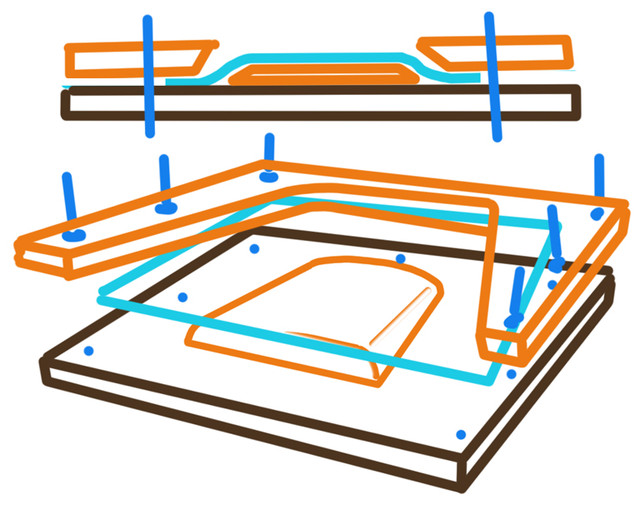

Here a quick and dirty illustration of what I'd do.

The scoop in front would be similar pressed process and be then bolted to the piece to allow easy removal of the part once cured.

using a sheet as thin as you can find, you would not need much pressure to get the shape I see.

- Joined

- Jan 1, 2012

- Messages

- 8,555

- Reaction score

- 1,436

- Location

- Eugene, OR

- My Car

- 1971 Mustang Sportroof M code

Because the resin is so thick the bubbles escape slower than the resin hardens, so it's difficult to get the bubbles out that stirring the resin and hardner adds to it. Placing it in a vacuum helps

http://secondchancegarage.com/public4/casting-taillights-1.cfm

http://secondchancegarage.com/public4/casting-taillights-1.cfm

As I have great respect for those daring making their own parts, it's hard to write a remark as I did without hurting feelings. So really, I'm glad you see the constructive side of it.I really appreciate that! As for the bubbles, are you sure that it’s not just the bubbles them selves that are in the foam you are thinking about? The alu sheet was also a nice idea. But I actually like to work with this fiberglass, you can also change something if it isnt as you want it

When I've moved in this country a zillion years ago and started at zero. I've worked in a polyester company, making canoes and all kind of composites parts as a side activity while learning that weird language that is Dutch to find a job.

All that to say that I know a bit what trapped air can do. Hence why lots of parts were cured under vacuum. I let u decide if the bubbles are real or not. Just warning you in case they are real and near of top surface.

About the aluminium sheet, I did not extend, but while you could make it out of aluminum, I was thinking of pressing the shape to make a mould, you'd then have a perfect curve and smooth surface and then using gelcoat first, then resin no worries for bubbles and a whole lot less work to get your part as you want it.

Using plywood/mdf bigger than your sheet and have bolts do the hard work. Depending on shapes, the art is to find the ideal space between the two.

Here a quick and dirty illustration of what I'd do.

The scoop in front would be similar pressed process and be then bolted to the piece to allow easy removal of the part once cured.

using a sheet as thin as you can find, you would not need much pressure to get the shape I see.

Yeah it’s not allways easy to find the right way to write the things without hurting feeling, but you did’nt do that to me. If I can do anything better I’m allways open for advices and if there are anything I can do better, so thanks my friend

I’m really glad for you’re warning me, I have been thinking about making this panel as a kind of mold and maybe make it in carbonfiber instead and then ofcourse use a vacuum machine to do the job correctly, but I have’nt made my decision yet. But I will deffently keep in mind what you are saying and I’m glad that you are telling me those things, I appreciate that!

The idea with the aluminumsheet are very good and I see the idea in using a product with a smooth surface.

You are deffently right. Thanks for the link, it’s actually perfect because I need to make my own taillight lenses tooBecause the resin is so thick the bubbles escape slower than the resin hardens, so it's difficult to get the bubbles out that stirring the resin and hardner adds to it. Placing it in a vacuum helps

http://secondchancegarage.com/public4/casting-taillights-1.cfm

Took all the front suspension off again. I needed to blast some areas, finish up some weldings and just clean everything out so it will be ready for a rust preventing primer in the next couple of days. After that my plan is too smooth everything out to get the look that I want. For final choice of color it will have the same charcoal as the wheels and with a matte clear on, I think that will look amazing!

Have done a lot of work to the engine bay and I think this is fine now

Have done a lot of work to the engine bay and I think this is fine now

Last edited by a moderator:

Similar threads

- Replies

- 10

- Views

- 674