- Joined

- Jan 7, 2015

- Messages

- 8,032

- Reaction score

- 534

- Location

- Western North Carolina

- My Car

- Multiple Mustangs!

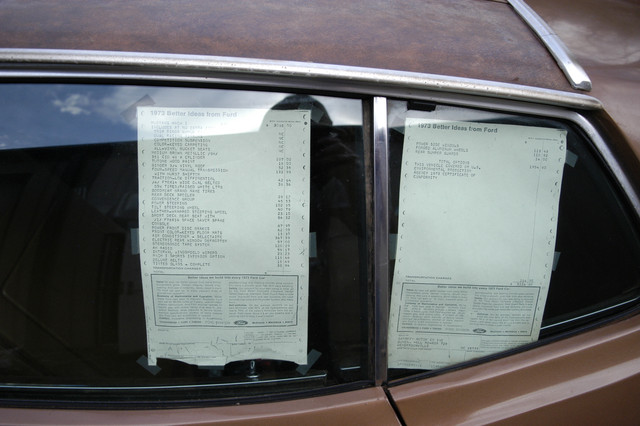

Well I have started doing some of the work that does not involve the car right now. I pulled some of the 1973 Forged Aluminum wheels down and have started cleaning and polishing them.

So let me state some facts on the wheels. Marti says that there were 10,106 total Mustangs made in 1973 with the Aluminum wheel option. Mavericks got the exact same 7" wide by 14" wheel with their own center cap. Mercury also used two different variations of this wheel with the only difference the center hole is larger to clear the larger hubs on a Mercury.

Not to miss lead anyone on how the wheels should look they were never polished from the factory. They were high speed turned using diamond tooling. They did not have any clear coat on them either. I did investigate having them turned again and the quote came back several hundred dollars per wheel. I do not have that kind of money to put into wheels so I will polish.

I got two done Monday in about 4 hours and almost got the other two done yesterday and had to quit. The process I am using is as follows.

Wash the wheel inside and out with Dawn.

Then wash with lacquer thinner to get any road tar off.

I blast the back side of the wheel with ground up walnut shells using 90 lbs. air pressure in cabinet. This also cleans out the lug bolt holes and around tire valves.

I wire brush the sealing bead area to remove any bits of tire left there.

I wet sand the face of the wheel with 1,200 grit paper.

I file any rough spots.

I did mask off the 5 slots that have a Mill finish to prevent polishing them.

Then I polish the wheel using 3/8" electric drill and cotton buffing wheel and Blue Magic Mag Wheel Polish paste. I wipe down with window cleaner and micro fiber towel.

I will put some new black satin paint in the detail ring around the outer edge.

Will be getting a new set of Goodyear Polyglass RWL tires F-70-14" like came on the car. When I get them mounted of course I will set all of the fill valves in same place and the tire logo the same on all of them.

Since it will sit in the museum for a while I will add RTV around the fill valves and also around the bead of the tire to keep them from slowly leaking down.

I have a set of NOS wheel center caps also. The price on the boxes was $14.00 each from a vendor at swap meet years ago. Originals have 5 screws and some of the replacements had three screws. They do repo them. Only have a couple of broke screws from the caps. Soaking in penetrating oil and will drill from the back side. Will use stainless and anti seize going back on.

I will build actual stands that will keep the weight of the car off the tires while on display. Will look like they are on the floor but no weight on them.

I did get a reply to my ad on Craigslist for help doing the cleaning. He came and visited the other day. He is a former Ford mechanic but has had to retire early due to MS. He wants to keep busy and is willing to help.

When we move the Mach 1 in the new garage will remove hood, fenders, grill and everything on the front. Will run all the suspension parts through the molasses tank. Engine and drive train will be pulled and engine compartment will be detailed. There will be no restoration done only clean and detail.

One of the cars that will be in the museum is another Barn Find. A 1964 1/2 that has been in barn for many years. They are tearing the barn down and bringing to the museum to put back up.

BTW I was puzzle at how few cars they could get into the museum. It turns out that Daniel Carpenter will be using the second story and will not be used by the museum.

So I only have about 1/4 of the last wheel to buff out. Works out to a little less that 2 hours per wheel. These were i pretty good shape so went pretty fast.

One thing I found out is that the Mustang emblem in the wheel centers is not always in the same position so when I have tires mounted and indexed to same position related to the tire valve I cannot do the same with the center caps. I guess they just dropped them in and staked them and did not worry about position of rotation.

If you are going to do this note in I think the last picture I put plastic electrical tape on the drill chuck to prevent hitting the wheel with the steel chuck. You do not need his speed rpm to polish especially with the Blue Magic paste. Lots of truckers use it on their big truck wheels. Will also work on your aluminum trim once you get the anodizing off.

Does anyone have any NOS lug nuts for the wheels? Part # DOOZ-1012-A I need 20 new ones if I can locate or rework existing.

So let me state some facts on the wheels. Marti says that there were 10,106 total Mustangs made in 1973 with the Aluminum wheel option. Mavericks got the exact same 7" wide by 14" wheel with their own center cap. Mercury also used two different variations of this wheel with the only difference the center hole is larger to clear the larger hubs on a Mercury.

Not to miss lead anyone on how the wheels should look they were never polished from the factory. They were high speed turned using diamond tooling. They did not have any clear coat on them either. I did investigate having them turned again and the quote came back several hundred dollars per wheel. I do not have that kind of money to put into wheels so I will polish.

I got two done Monday in about 4 hours and almost got the other two done yesterday and had to quit. The process I am using is as follows.

Wash the wheel inside and out with Dawn.

Then wash with lacquer thinner to get any road tar off.

I blast the back side of the wheel with ground up walnut shells using 90 lbs. air pressure in cabinet. This also cleans out the lug bolt holes and around tire valves.

I wire brush the sealing bead area to remove any bits of tire left there.

I wet sand the face of the wheel with 1,200 grit paper.

I file any rough spots.

I did mask off the 5 slots that have a Mill finish to prevent polishing them.

Then I polish the wheel using 3/8" electric drill and cotton buffing wheel and Blue Magic Mag Wheel Polish paste. I wipe down with window cleaner and micro fiber towel.

I will put some new black satin paint in the detail ring around the outer edge.

Will be getting a new set of Goodyear Polyglass RWL tires F-70-14" like came on the car. When I get them mounted of course I will set all of the fill valves in same place and the tire logo the same on all of them.

Since it will sit in the museum for a while I will add RTV around the fill valves and also around the bead of the tire to keep them from slowly leaking down.

I have a set of NOS wheel center caps also. The price on the boxes was $14.00 each from a vendor at swap meet years ago. Originals have 5 screws and some of the replacements had three screws. They do repo them. Only have a couple of broke screws from the caps. Soaking in penetrating oil and will drill from the back side. Will use stainless and anti seize going back on.

I will build actual stands that will keep the weight of the car off the tires while on display. Will look like they are on the floor but no weight on them.

I did get a reply to my ad on Craigslist for help doing the cleaning. He came and visited the other day. He is a former Ford mechanic but has had to retire early due to MS. He wants to keep busy and is willing to help.

When we move the Mach 1 in the new garage will remove hood, fenders, grill and everything on the front. Will run all the suspension parts through the molasses tank. Engine and drive train will be pulled and engine compartment will be detailed. There will be no restoration done only clean and detail.

One of the cars that will be in the museum is another Barn Find. A 1964 1/2 that has been in barn for many years. They are tearing the barn down and bringing to the museum to put back up.

BTW I was puzzle at how few cars they could get into the museum. It turns out that Daniel Carpenter will be using the second story and will not be used by the museum.

So I only have about 1/4 of the last wheel to buff out. Works out to a little less that 2 hours per wheel. These were i pretty good shape so went pretty fast.

One thing I found out is that the Mustang emblem in the wheel centers is not always in the same position so when I have tires mounted and indexed to same position related to the tire valve I cannot do the same with the center caps. I guess they just dropped them in and staked them and did not worry about position of rotation.

If you are going to do this note in I think the last picture I put plastic electrical tape on the drill chuck to prevent hitting the wheel with the steel chuck. You do not need his speed rpm to polish especially with the Blue Magic paste. Lots of truckers use it on their big truck wheels. Will also work on your aluminum trim once you get the anodizing off.

Does anyone have any NOS lug nuts for the wheels? Part # DOOZ-1012-A I need 20 new ones if I can locate or rework existing.