MeZapU

Well-known member

- Joined

- Feb 12, 2011

- Messages

- 830

- Reaction score

- 11

- Location

- Southery, UK

- My Car

- 12 GT

73 Mach 1

85 GT

66 F-100

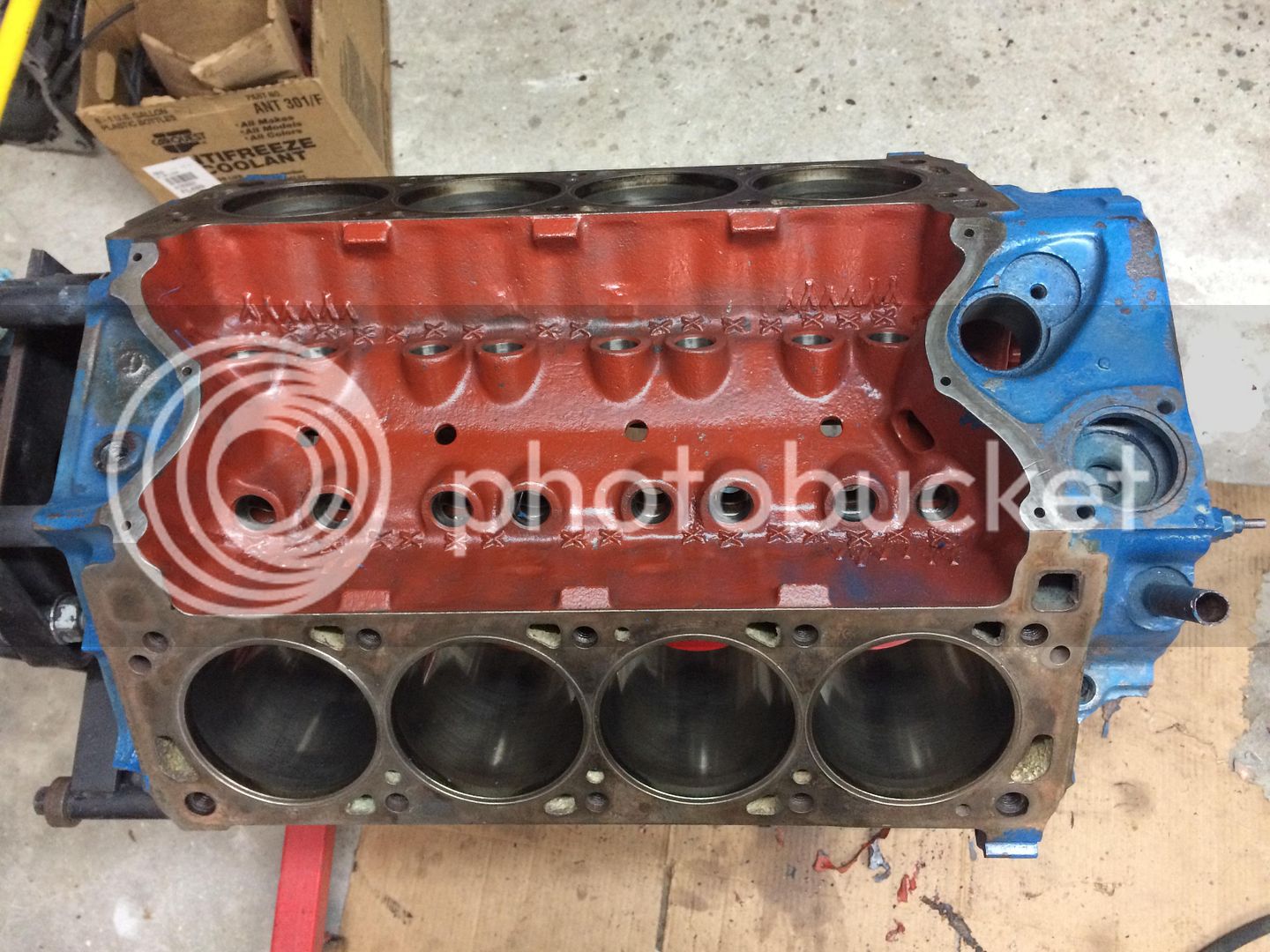

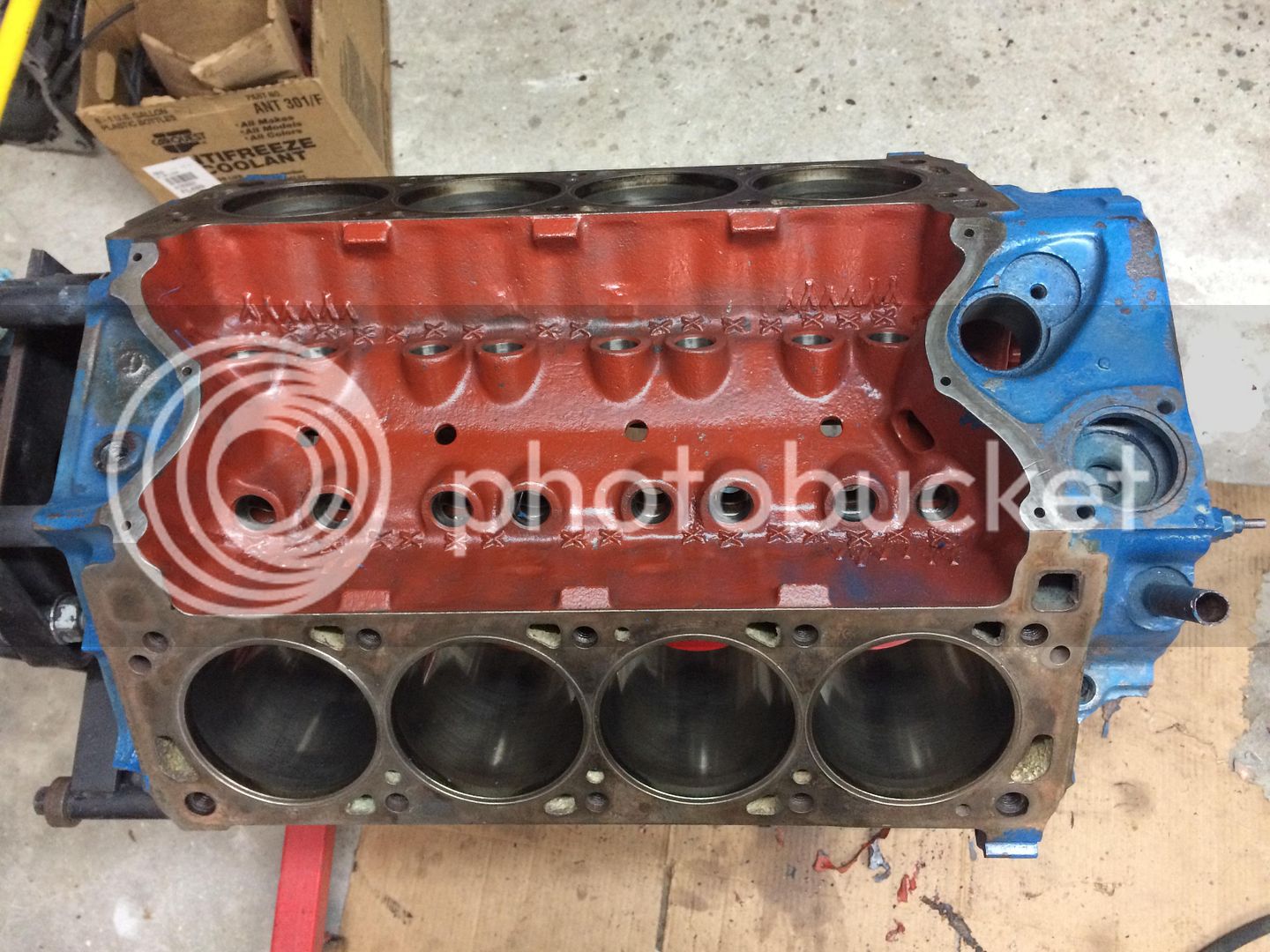

This weekend I picked up what I hope will be a good block for my new 351c build. It is an Aussie 351c and has some interesting differences. "D2 E-CA" block casting. Casting date has it as a 1977 and we know in the USA they stopped making Clevelands in 1974. The main caps are different as well. No less beefy but they have a different looking set of numbers and arrows.

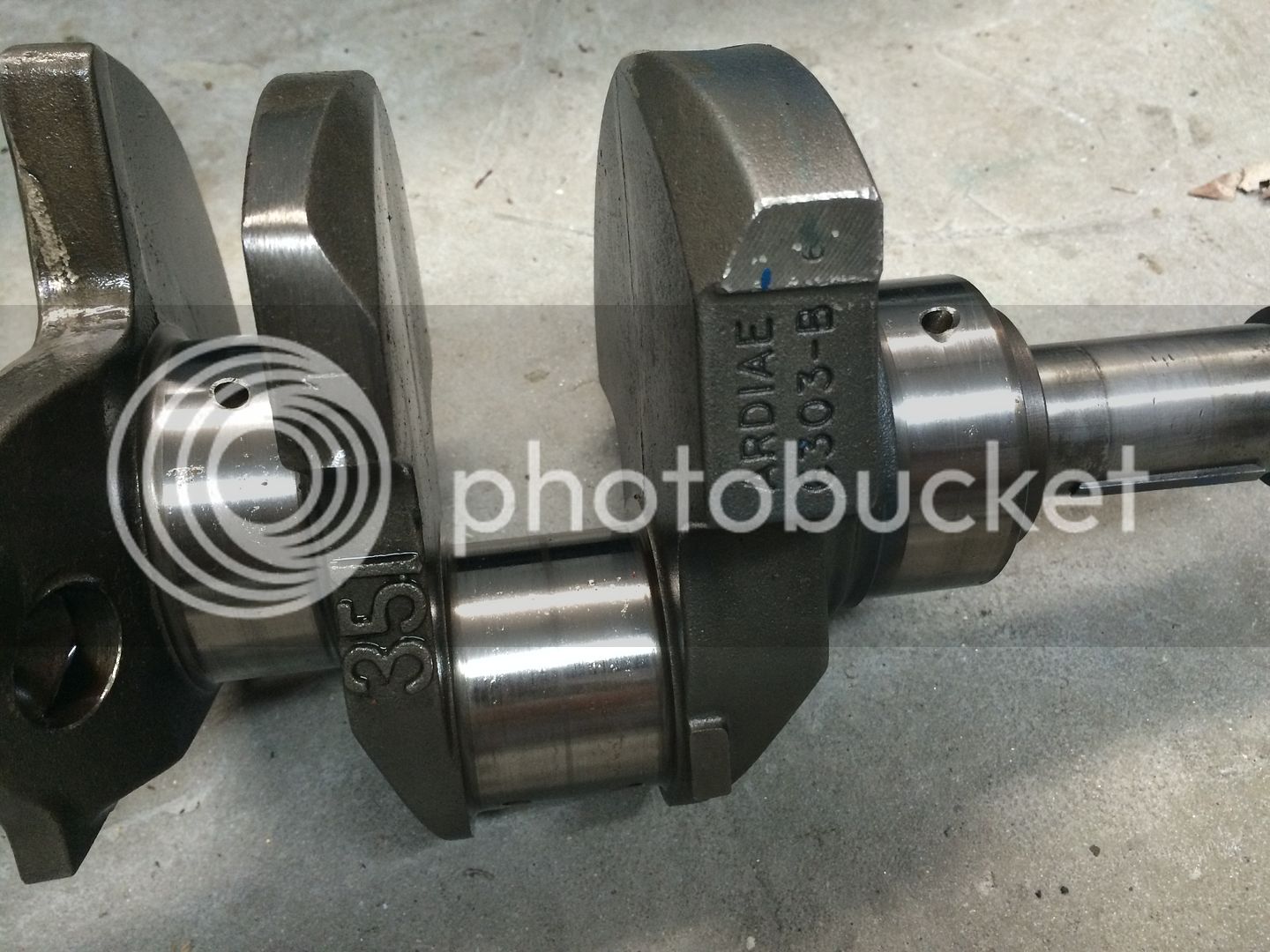

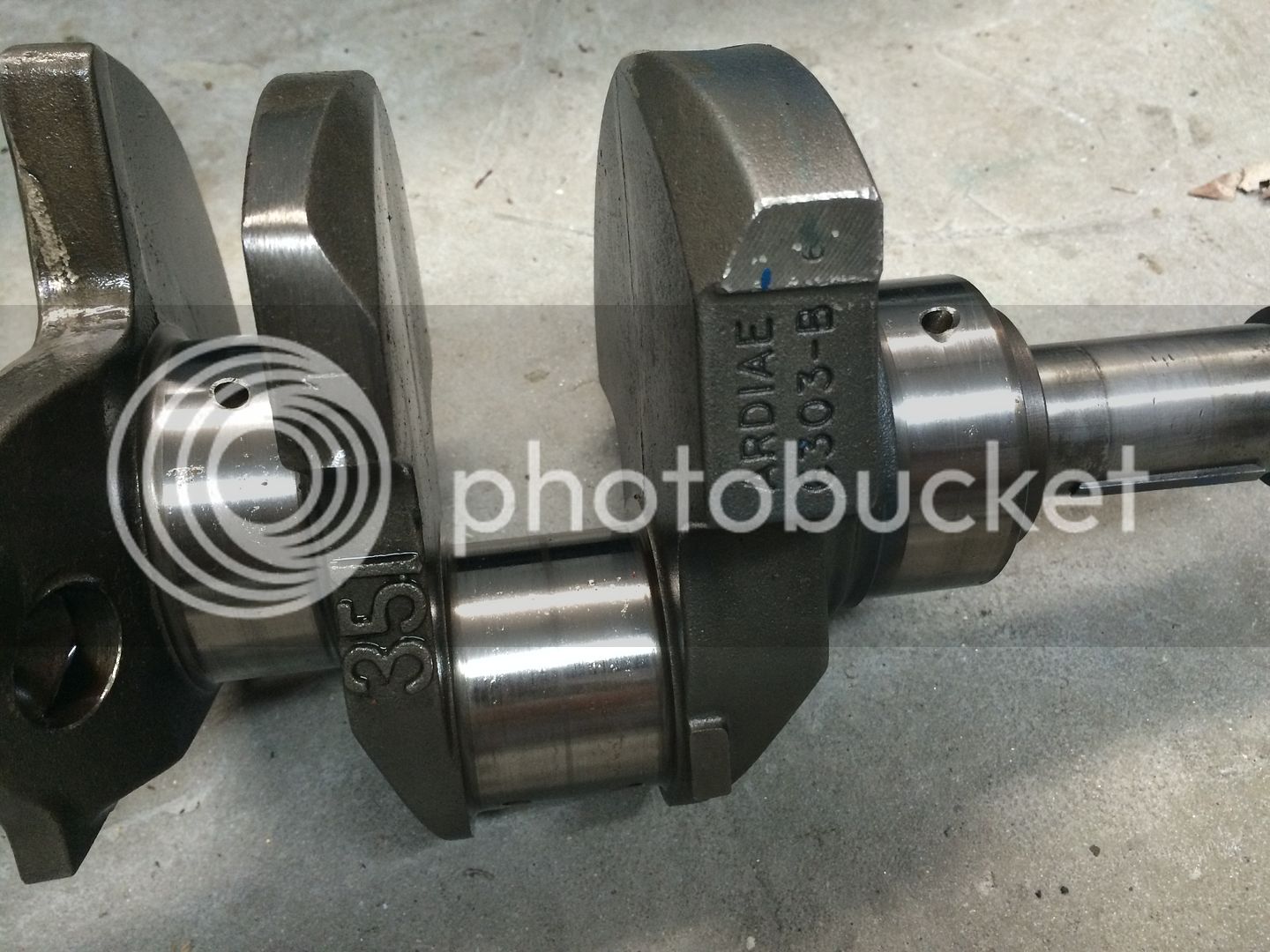

This one already has some quality machine work and upgrades. Deburred, o-ringed, .030 over, Aussie crank was standard/standard and the bearings look perfect. Connecting rods have been rebuilt, beams ground and shot peened, I believe Moroso rod bolts as they are not stockers but do not have ARP on them. They do have the stretch gauge alignment dimples. Balanced rotating assy. Has the Moroso oil restrictor mods. Bores look awesome and the rings are perfect. I doubt this engine has seen 500 miles. Tight Rollmaster timing chain that I will be reusing. I put the carbon'd up pistons in my ultrasonic cleaner and they came out like new. Didn't even need to take the rings off. I love that thing. The only downer is the pistons are cast Silv-O-Lites.

I plan on using a std/std 4MAB crank that I have and using a quality aftermarket connecting rod and Ross Piston combo to handle some RPM's.

The heads are at the machine shop. I'm talking with the shop and my Camshaft guy, trying to nail down a valve spring combo.

It will be a slow build but a fun one. I tried to upload more pictures but Photobucket gives you a hard time if you try and do too many per day. I'll update this post as time goes on.

Piston as it came out of the shortblock

One cycle through the ultrasonic cleaner

Two cycles

After a 4th cycle.

This one already has some quality machine work and upgrades. Deburred, o-ringed, .030 over, Aussie crank was standard/standard and the bearings look perfect. Connecting rods have been rebuilt, beams ground and shot peened, I believe Moroso rod bolts as they are not stockers but do not have ARP on them. They do have the stretch gauge alignment dimples. Balanced rotating assy. Has the Moroso oil restrictor mods. Bores look awesome and the rings are perfect. I doubt this engine has seen 500 miles. Tight Rollmaster timing chain that I will be reusing. I put the carbon'd up pistons in my ultrasonic cleaner and they came out like new. Didn't even need to take the rings off. I love that thing. The only downer is the pistons are cast Silv-O-Lites.

I plan on using a std/std 4MAB crank that I have and using a quality aftermarket connecting rod and Ross Piston combo to handle some RPM's.

The heads are at the machine shop. I'm talking with the shop and my Camshaft guy, trying to nail down a valve spring combo.

It will be a slow build but a fun one. I tried to upload more pictures but Photobucket gives you a hard time if you try and do too many per day. I'll update this post as time goes on.

Piston as it came out of the shortblock

One cycle through the ultrasonic cleaner

Two cycles

After a 4th cycle.

Last edited by a moderator: