- Joined

- Jan 12, 2017

- Messages

- 269

- Reaction score

- 0

- Location

- USA - Florida

- My Car

- 1972 Mustang Mach 1

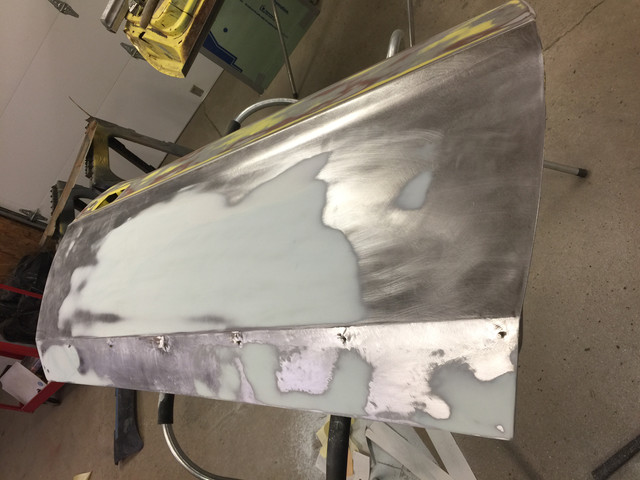

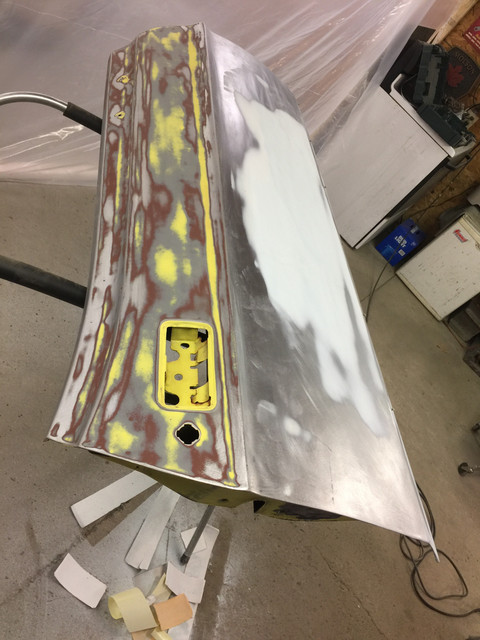

2011 Mustang GT

Wow...nice work! As I look through this thread I picture my newly acquired Mach 1 going through most of the same repairs, rear, trunk, LH quarter, fenders, et. It's interesting to see all the work you have done so far and the progress you have made. Question...when you say you can repair the doors how do you eliminate and stop the rust that could be inside of the door. It seems like it would be a similar dilemma to the Mach 1 hoods. Mine has rust inside the ram air cowl portion of the hood between the separate pieces of sheet metal. The suggestions I received were to either acid dip (which not many agree with due to issues) or just get a repro hood. Seems like it would just be easier to get new doors but if you are skilled as you obviously are and can get rid of the rust then it's best to stay original I suppose.

I will definitely keep following your build. Thanks for sharing!

I will definitely keep following your build. Thanks for sharing!