And and go on.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Travails of the Trailer Queen

- Thread starter mach1mama

- Start date

Help Support 7173Mustangs.com:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 5, 2010

- Messages

- 6,687

- Reaction score

- 389

- Location

- Grand Rapids, MI

- My Car

- 73 Convertible

Nice write-up and good progress.

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

Part 6 (originally posted 06 Feb 2011)

Engine

As of today the engine has been broken down, cleaned and magnafluxed for cracks (none found) all components have been chucked with the exception of the block, crankshaft, heads and alternator. The stock exhaust manifold, intake and carburator will be retained and returned to my wife. This engine held a few surprises for my wife, before I get into that I have to give you all a quick history of the 351 Cleveland first.

Searching the Web there is a lot misinformation and confusion over this engine. The Cleveland engine was produced from 1970 – 1974 in North America but continued to be produced in Australia into the ‘80’s. Often confused with the 351 Windsor the only similarities start and stop with the displacement, very few of the components are compatible other than the heads (with minor machining) and a few minor components. The Cleveland’s claim to fame is derived from it heads, which feature huge intake and exhaust valves and associated ports. Furthermore in order to fit these large valves they had to be canted which made the heads exotic for the time. These engines were produced in two types, the standard 2V (2 barrel carb) and 4V (4 barrel carb) heads, both have very different intake and exhaust manifolds and from what I understand are not interchangeable, the difference being that the 4V heads had even larger valves than the 2V version which required larger intake and exhaust ports. Eventhough the 4V Cleveland’s were favoured by NASCAR and drag racers they were available for use in Mustangs, Cougars and Torinos, De Tomaso Panteras and other cars as well. Only about 8% of the engines producced were of the 4V type, the remaining 92% were of the standard 2V variety. The 4V heads flowed so well that Ford fitted them on the 302 Windsor to produce the famous and valuable ’69 - 70 Boss 302. From '70 to '74 there where no less than 6 variants of this engine in both 2V and 4V configurations (2V, 4V, Boss 351, HO, various Cobra Jets). Even more confusing, in ’73 the 351 Clevelands fitted with the 4V heads (the heads are embossed with the number 4) actually had the smaller 2V valves (probably due to meeting new emissions standards). On top of this were the tall deck version of the Cleveland family, the 351M/400, used in mid/full size cars and light trucks. If that wasn’t confusing enough, there is also the issue of which ones had 2 or 4 bolt mains, although it was commonly thought all 4V engines also had 4 bolt main blocks and 2V had 2 bolt mains, it was not always the case (from Kelly Hotrod – Ford Engine “Hobby consensus is that Ford mixed these in production. 2 bolt blocks have been found on 4V’s and 4 bolt blocks on family cars”), so you never know what you’ve got until you remove the oil pan.

There is much discussion on what caused the demise the Cleveland, the truth appears to be the simple fact the Cleveland was heavier, more expensive (due to the design of the heads) and more importantly could not meet the new emissions standards as easily as the Windsor engine. Despite the Cleveland’s relatively short reign there are aftermarket parts available, unfortunately most of these part are for the more popular 2V design, parts for 4V are available but there are there very few vendors and they are mostly geared for competitive applications. For example, after much research, there are only three headers available for ’73 351C 4V and one of them are full blown racing headers. Another example, as you know even though my wife’s '73 has 4V heads, they are fitted with 2V sized valves, knowing this she decided that if she had 4V heads she wanted the larger 4V valves. With this decision made, her engine builder agreed to do the necessary machining. However after a quick search the only 4V valves available are made of stainless steel Boss valves, not something you typically see on a street machine.

OK, enough of the history lesson, as I mentioned in the opening line of this part I this engine held a few surprises. First off, the engine died because the timing chain had in fact skipped two teeth, bending two pushrods and destroying the distributor in the process. During the disassembly process one engine mount and seven exhaust header bolts snapped, all them below the surface. As previoulsy stated although the heads are of the 4V type they are fitted with the smaller 2V valves, and the good news, she’s got a 4 bolt main block. But the biggest surprise is the condition of the block, despite having 98,000 miles on the odometer the cylinder walls are almost pristine, there isn’t even a ridge at the top of the cylinder wall. The wife’s engine builder told no machining is required, just a honing.

Bent push rods.

Grimy, sludgy heads.

I’m not a mechanic but I believe the car was running rich. What say you?

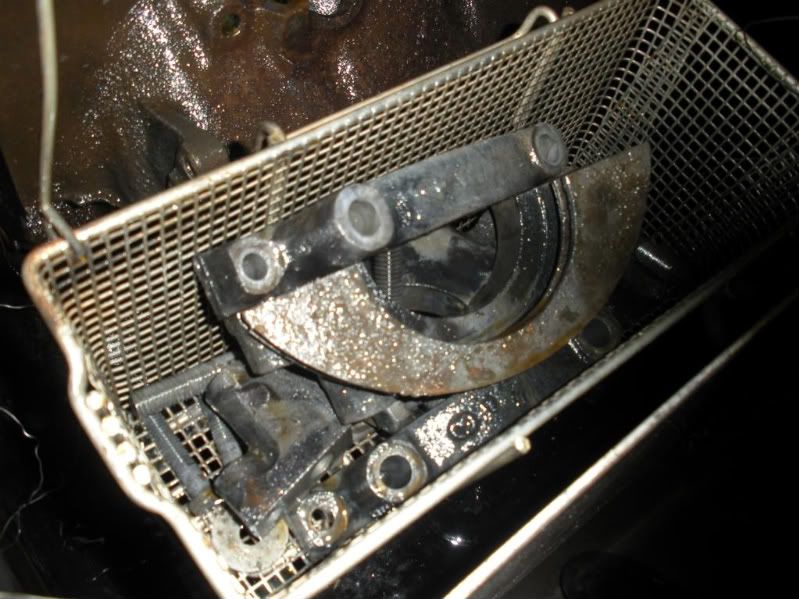

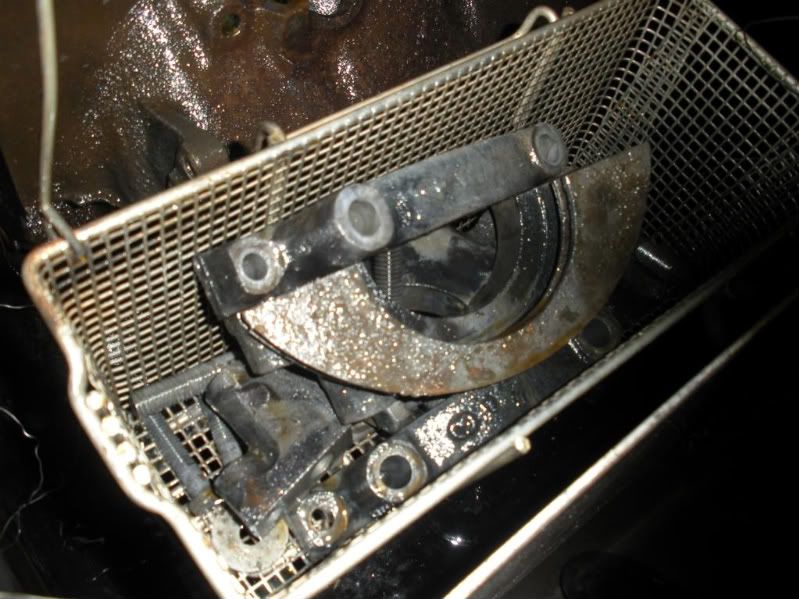

Fresh from the bath.

Heads being magnafluxed by Brian Hackett, owner of Trick-Engines.

Look at the size of those ports and valve openings (and these are the stock 2V openings). Notice the snapped bolts?

If I’m reading this right this block was cast on 06 December 1972 (a Wednesday, lucky wife).

A clean block.

Enjoy the four bolt main goodness.

Smooth, untouched cylinders.

And the parts start coming in.

End of part 6. Part 7 to follow.

Engine

As of today the engine has been broken down, cleaned and magnafluxed for cracks (none found) all components have been chucked with the exception of the block, crankshaft, heads and alternator. The stock exhaust manifold, intake and carburator will be retained and returned to my wife. This engine held a few surprises for my wife, before I get into that I have to give you all a quick history of the 351 Cleveland first.

Searching the Web there is a lot misinformation and confusion over this engine. The Cleveland engine was produced from 1970 – 1974 in North America but continued to be produced in Australia into the ‘80’s. Often confused with the 351 Windsor the only similarities start and stop with the displacement, very few of the components are compatible other than the heads (with minor machining) and a few minor components. The Cleveland’s claim to fame is derived from it heads, which feature huge intake and exhaust valves and associated ports. Furthermore in order to fit these large valves they had to be canted which made the heads exotic for the time. These engines were produced in two types, the standard 2V (2 barrel carb) and 4V (4 barrel carb) heads, both have very different intake and exhaust manifolds and from what I understand are not interchangeable, the difference being that the 4V heads had even larger valves than the 2V version which required larger intake and exhaust ports. Eventhough the 4V Cleveland’s were favoured by NASCAR and drag racers they were available for use in Mustangs, Cougars and Torinos, De Tomaso Panteras and other cars as well. Only about 8% of the engines producced were of the 4V type, the remaining 92% were of the standard 2V variety. The 4V heads flowed so well that Ford fitted them on the 302 Windsor to produce the famous and valuable ’69 - 70 Boss 302. From '70 to '74 there where no less than 6 variants of this engine in both 2V and 4V configurations (2V, 4V, Boss 351, HO, various Cobra Jets). Even more confusing, in ’73 the 351 Clevelands fitted with the 4V heads (the heads are embossed with the number 4) actually had the smaller 2V valves (probably due to meeting new emissions standards). On top of this were the tall deck version of the Cleveland family, the 351M/400, used in mid/full size cars and light trucks. If that wasn’t confusing enough, there is also the issue of which ones had 2 or 4 bolt mains, although it was commonly thought all 4V engines also had 4 bolt main blocks and 2V had 2 bolt mains, it was not always the case (from Kelly Hotrod – Ford Engine “Hobby consensus is that Ford mixed these in production. 2 bolt blocks have been found on 4V’s and 4 bolt blocks on family cars”), so you never know what you’ve got until you remove the oil pan.

There is much discussion on what caused the demise the Cleveland, the truth appears to be the simple fact the Cleveland was heavier, more expensive (due to the design of the heads) and more importantly could not meet the new emissions standards as easily as the Windsor engine. Despite the Cleveland’s relatively short reign there are aftermarket parts available, unfortunately most of these part are for the more popular 2V design, parts for 4V are available but there are there very few vendors and they are mostly geared for competitive applications. For example, after much research, there are only three headers available for ’73 351C 4V and one of them are full blown racing headers. Another example, as you know even though my wife’s '73 has 4V heads, they are fitted with 2V sized valves, knowing this she decided that if she had 4V heads she wanted the larger 4V valves. With this decision made, her engine builder agreed to do the necessary machining. However after a quick search the only 4V valves available are made of stainless steel Boss valves, not something you typically see on a street machine.

OK, enough of the history lesson, as I mentioned in the opening line of this part I this engine held a few surprises. First off, the engine died because the timing chain had in fact skipped two teeth, bending two pushrods and destroying the distributor in the process. During the disassembly process one engine mount and seven exhaust header bolts snapped, all them below the surface. As previoulsy stated although the heads are of the 4V type they are fitted with the smaller 2V valves, and the good news, she’s got a 4 bolt main block. But the biggest surprise is the condition of the block, despite having 98,000 miles on the odometer the cylinder walls are almost pristine, there isn’t even a ridge at the top of the cylinder wall. The wife’s engine builder told no machining is required, just a honing.

Bent push rods.

Grimy, sludgy heads.

I’m not a mechanic but I believe the car was running rich. What say you?

Fresh from the bath.

Heads being magnafluxed by Brian Hackett, owner of Trick-Engines.

Look at the size of those ports and valve openings (and these are the stock 2V openings). Notice the snapped bolts?

If I’m reading this right this block was cast on 06 December 1972 (a Wednesday, lucky wife).

A clean block.

Enjoy the four bolt main goodness.

Smooth, untouched cylinders.

And the parts start coming in.

End of part 6. Part 7 to follow.

Last edited by a moderator:

- Joined

- Jul 2, 2010

- Messages

- 6,614

- Reaction score

- 121

- Location

- Warrenton, Virginia 20186

- My Car

- 73 Mustang Conv.

01 Mustang Bullitt (my son owns now)

04 Oxford White Mach 1

04 Azure Blue Mach 1 (sold)

Great information.

Question about the block date code; I'm not up to speed on these codes but if the date is December 6, 1973, wouldn't that be after the 73 Mustang was out of production? The Mustang II would have come out by then.

Question about the block date code; I'm not up to speed on these codes but if the date is December 6, 1973, wouldn't that be after the 73 Mustang was out of production? The Mustang II would have come out by then.

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

This is mach1mama's husband writing. You'r absolutely right. It's a typo on my part, I can't believe I missed that after the countless times I've reviewed and proof read this series. I'm going to correct the error, thanks for the heads up.Great information.

Question about the block date code; I'm not up to speed on these codes but if the date is December 6, 1973, wouldn't that be after the 73 Mustang was out of production? The Mustang II would have come out by then.

- Joined

- Feb 19, 2011

- Messages

- 1,228

- Reaction score

- 4

- Location

- Southern Arizona

- My Car

- 1971 Mustang Grande,

1973 MAch 1

I love history!

And pictures to boot. This is good!

And pictures to boot. This is good!

$18.77

$24.95

Ford Mustang Pony Racing Stripe 5.0 Muscle Shelby Long Sleeve T-Shirt Front Back Print-Black-Large

Giftware Shop Usa

$119.99

Polished Rocker Panel Sill Plate Molding Kit with Clips Compatible with 1964-1966 Ford Mustang - Authentic Restoration for Classic Car Enthusiasts

Classic 2 Current Fabrication

$9.00

2016 Hot Wheels Vintage American Muscle 1970 FORD MUSTANG MACH 1 die-cast 4/10

Cards and Bobbles

$69.98

JH DESIGN GROUP Men's Ford Mustang Collage Black Zip Up Hoodie Sweatshirt (Large, CLG2-black)

Affordable Family Clothing

$22.98

JH Design Women's Ford Mustang T-Shirt's in 2 Styles Short Sleeve Crew Neck Shirts (as1, Alpha, l, Regular, Regular, CLG4-black/pink)

Affordable Family Clothing

$19.99

Checkered Flag Sports Ford Mustang Baseball Cap for Men - Logo Car Racing Hat Heather Gray, One Size

West Coast Corvette / Camaro

$34.95

$55.00

The Complete Book of Ford Mustang: Every Model Since 1964-1/2 (Complete Book Series)

Amazon.com

$29.70

$35.95

Ford Mustang, Mach 1, GT, Shelby, & Boss V-8 (64-73) Haynes Repair Manual

Haynes Repair Manuals

$18.99

Checkered Flag Men's Ford Mustang Cap Tri-Bar Pony Logo Adjustable Black Hat

The First Class Realtor

$39.39

$60.00

Shelby American 60 Years of High Performance: The Stories Behind the Cobra, Daytona, Mustang GT350 and GT500, Ford GT40 and More

Caliber Brands

$13.75

$16.39

Ford Mustang: Trivia & Fun Facts Every Fan Should Know About The Great American Icon!

Amazon.com

- Joined

- Sep 13, 2010

- Messages

- 7,952

- Reaction score

- 472

Another example, as you know even though my wife’s '73 has 4V heads, they are fitted with 2V sized valves, knowing this she decided that if she had 4V heads she wanted the larger 4V valves.

Never heard of this..............How is it even possible:huh:

Never heard of this..............How is it even possible:huh:

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

This is mach1mama's husband again.Another example, as you know even though my wife’s '73 has 4V heads, they are fitted with 2V sized valves, knowing this she decided that if she had 4V heads she wanted the larger 4V valves.

Never heard of this..............How is it even possible:huh:

That's right, it took a while for me to wrap my head around it as well. According to MustangTeck heads section.

D1AE-CB, 71-74 351C (2V), Valves 2.04 / 1.65

DOAE-6090-M,N,R or DOAE-N or D1ZE-DA,

70-72 351C (4V) Valves 2.19 / 1.71

D3ZE-AA, 73-74 351C CJ (4V), Valves 2.04 / 1.66

As can be seen although the '73-'74 351C CJ (by default CJ=4V heads) have 4V heads they were fitted with 2V valves.

Furthermore, from 351Cleveland.net / Cleveland Wiki / intro page / An introductory page on the on the Q code Cleveland by Tom Custom.

"1973:

H code 351C-2V, two barrel engine, 8:1 CR (or so), open 2V style heads

Q code: Cobra Jet 4V 8:1 CR (or so) four barrel engine. Same as 1972 but got the 2V sized valves in the 4V heads. Cam was retarded in timing 4 degrees sometime starting in 1972. The change is in the cam. It gets an EGR system. Only 4V Cleveland engine option in 1973/74.

The 1973 Q code used a special air cleaner housing with the usual snorkel on the right side, a second air inlet controlled by a vacuum servo on the left (US driver's) side, and a chrome lid. Transmissions with the CJ were either the Toploader (only close ratio available in 1973) or the C6 with a special smaller diameter, high stall torque converter. Dual points only with 4 speed. All CJ years cam with a cast iron spread bore intake manifold."

1973 was an orphan year for the Mustang, what with having emmisions equipment installed (the EGR valve and plate made it impossible to fit the underhood Ram Air components eventhough the Mach 1 had the Ram Air hood) which was probably why they used the smaller valves. Also trying to find a modern carburator to fit the intake manifold of the OEM spread bore 4300 was an exercise in futility.

As a graphic representation, compare the pictures of the stock valve openings shown in part 6 with upcoming pictures of the proper 4V valves in an upcoming part, you'll notice the difference.

If anyone else has any more info on this topic I would really like to see it.

- Joined

- Jul 2, 2010

- Messages

- 6,614

- Reaction score

- 121

- Location

- Warrenton, Virginia 20186

- My Car

- 73 Mustang Conv.

01 Mustang Bullitt (my son owns now)

04 Oxford White Mach 1

04 Azure Blue Mach 1 (sold)

Wow, very complicated. It looks like you really did your homework.This is mach1mama's husband again.Another example, as you know even though my wife’s '73 has 4V heads, they are fitted with 2V sized valves, knowing this she decided that if she had 4V heads she wanted the larger 4V valves.

Never heard of this..............How is it even possible:huh:

That's right, it took a while for me to wrap my head around it as well. According to MustangTeck heads section.

D1AE-CB, 71-74 351C (2V), Valves 2.04 / 1.65

DOAE-6090-M,N,R or DOAE-N or D1ZE-DA,

70-72 351C (4V) Valves 2.19 / 1.71

D3ZE-AA, 73-74 351C CJ (4V), Valves 2.04 / 1.66

As can be seen although the '73-'74 351C CJ (by default CJ=4V heads) have 4V heads they were fitted with 2V valves.

Furthermore, from 351Cleveland.net / Cleveland Wiki / intro page / An introductory page on the on the Q code Cleveland by Tom Custom.

"1973:

H code 351C-2V, two barrel engine, 8:1 CR (or so), open 2V style heads

Q code: Cobra Jet 4V 8:1 CR (or so) four barrel engine. Same as 1972 but got the 2V sized valves in the 4V heads. Cam was retarded in timing 4 degrees sometime starting in 1972. The change is in the cam. It gets an EGR system. Only 4V Cleveland engine option in 1973/74.

The 1973 Q code used a special air cleaner housing with the usual snorkel on the right side, a second air inlet controlled by a vacuum servo on the left (US driver's) side, and a chrome lid. Transmissions with the CJ were either the Toploader (only close ratio available in 1973) or the C6 with a special smaller diameter, high stall torque converter. Dual points only with 4 speed. All CJ years cam with a cast iron spread bore intake manifold."

1973 was an orphan year for the Mustang, what with having emmisions equipment installed (the EGR valve and plate made it impossible to fit the underhood Ram Air components eventhough the Mach 1 had the Ram Air hood) which was probably why they used the smaller valves. Also trying to find a modern carburator to fit the intake manifold of the OEM spread bore 4300 was an exercise in futility.

As a graphic representation, compare the pictures of the stock valve openings shown in part 6 with upcoming pictures of the proper 4V valves in an upcoming part, you'll notice the difference.

If anyone else has any more info on this topic I would really like to see it.

- Joined

- Sep 13, 2010

- Messages

- 7,952

- Reaction score

- 472

This is mach1mama's husband again.Another example, as you know even though my wife’s '73 has 4V heads, they are fitted with 2V sized valves, knowing this she decided that if she had 4V heads she wanted the larger 4V valves.

Never heard of this..............How is it even possible:huh:

That's right, it took a while for me to wrap my head around it as well. According to MustangTeck heads section.

D1AE-CB, 71-74 351C (2V), Valves 2.04 / 1.65

DOAE-6090-M,N,R or DOAE-N or D1ZE-DA,

70-72 351C (4V) Valves 2.19 / 1.71

D3ZE-AA, 73-74 351C CJ (4V), Valves 2.04 / 1.66

As can be seen although the '73-'74 351C CJ (by default CJ=4V heads) have 4V heads they were fitted with 2V valves.

Furthermore, from 351Cleveland.net / Cleveland Wiki / intro page / An introductory page on the on the Q code Cleveland by Tom Custom.

"1973:

H code 351C-2V, two barrel engine, 8:1 CR (or so), open 2V style heads

Q code: Cobra Jet 4V 8:1 CR (or so) four barrel engine. Same as 1972 but got the 2V sized valves in the 4V heads. Cam was retarded in timing 4 degrees sometime starting in 1972. The change is in the cam. It gets an EGR system. Only 4V Cleveland engine option in 1973/74.

The 1973 Q code used a special air cleaner housing with the usual snorkel on the right side, a second air inlet controlled by a vacuum servo on the left (US driver's) side, and a chrome lid. Transmissions with the CJ were either the Toploader (only close ratio available in 1973) or the C6 with a special smaller diameter, high stall torque converter. Dual points only with 4 speed. All CJ years cam with a cast iron spread bore intake manifold."

1973 was an orphan year for the Mustang, what with having emmisions equipment installed (the EGR valve and plate made it impossible to fit the underhood Ram Air components eventhough the Mach 1 had the Ram Air hood) which was probably why they used the smaller valves. Also trying to find a modern carburator to fit the intake manifold of the OEM spread bore 4300 was an exercise in futility.

As a graphic representation, compare the pictures of the stock valve openings shown in part 6 with upcoming pictures of the proper 4V valves in an upcoming part, you'll notice the difference.

If anyone else has any more info on this topic I would really like to see it.

Wow I thought all 71/73 4v heads had (4V) Valves 2.19 / 1.71

Should have known 73 would be differant

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

This is mach1mama's husband.Wow, very complicated. It looks like you really did your homework.

One thing we've learnt prior to doing the rebuild on the "Trailer Queen" was the importance of research, research, research. Because if you don't you could make very costly and time consuming mistakes. This write is a year old and we're still doing research and learning new things.

Last edited by a moderator:

Hmm. I've seen the small valve '73 heads before, but I read differing things... That it was all 73, or late 73 had small, and that some early '73 had large valves. guess I'll find out when I swap my quench heads on what I had..

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

This is mach1mama's husband.Hmm. I've seen the small valve '73 heads before, but I read differing things... That it was all 73, or late 73 had small, and that some early '73 had large valves. guess I'll find out when I swap my quench heads on what I had..

Yup! Back in the day Ford used to mix and match such stuff. Remember this a time before computer control/tracking/management. By the way, I'm interested in knowing if you have a four bolt main and what carburator came stock with your '73.

Last edited by a moderator:

Wow 2v valves in 4v heads that's news to me.

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

Part 7 (originally posted 15 Feb 2011)

Due to the foul weather and delays in getting certain parts not much has been accomplished since my last instalment. However, the body work is complete, the only parts outstanding for the engine rebuild are the cam shaft bearings and we are awaiting delivery of the brake kits (my wife wasn’t aware that the slotted rotors she wants are special order). Despite this lack of progress I’ll post pictures of some the items that will eventually be installed on the wife’s Mach 1.

First, these are parts needed to make the Ram Air hood functional, my wife had the metal parts powder coated. The air cleaner cover is missing as it will receive a custom air-brush treatment.

The new wheels have arrived and new rubber have been mounted. The wheels are American Racing, Hot Rod, Torque Thrust II, Polished Aluminum.

The wife went with a staggered set-up with 16 X 7 in front and 16 X 8 for the rear.

The tires are Michellin Pilot Sport AS Plus, the fronts are 225/55 ZR 16

The rear tires are 245/50 ZR 16.

I didn’t know that the wheels are welded.

And for a little “bling” she got chrome valve stems.

Finally her ceramic coated (inside and outside) stainless long tube headers.

End of part 7. Part 8 to follow.

Due to the foul weather and delays in getting certain parts not much has been accomplished since my last instalment. However, the body work is complete, the only parts outstanding for the engine rebuild are the cam shaft bearings and we are awaiting delivery of the brake kits (my wife wasn’t aware that the slotted rotors she wants are special order). Despite this lack of progress I’ll post pictures of some the items that will eventually be installed on the wife’s Mach 1.

First, these are parts needed to make the Ram Air hood functional, my wife had the metal parts powder coated. The air cleaner cover is missing as it will receive a custom air-brush treatment.

The new wheels have arrived and new rubber have been mounted. The wheels are American Racing, Hot Rod, Torque Thrust II, Polished Aluminum.

The wife went with a staggered set-up with 16 X 7 in front and 16 X 8 for the rear.

The tires are Michellin Pilot Sport AS Plus, the fronts are 225/55 ZR 16

The rear tires are 245/50 ZR 16.

I didn’t know that the wheels are welded.

And for a little “bling” she got chrome valve stems.

Finally her ceramic coated (inside and outside) stainless long tube headers.

End of part 7. Part 8 to follow.

- Joined

- Feb 19, 2011

- Messages

- 1,228

- Reaction score

- 4

- Location

- Southern Arizona

- My Car

- 1971 Mustang Grande,

1973 MAch 1

Nice details.

mach1mama

Well-known member

- Joined

- Jan 8, 2012

- Messages

- 156

- Reaction score

- 1

- Location

- nova scotia, canada

- My Car

- 1973 Mach 1, 351 cleveland cobra jet engine. Gold glow, ginger interior. Long tube headers. completely rebuilt engine. Forged piston, roller rockers. lifters. Comp cams. Edelbrook carb and intake. Trush mufflers stainless steele custom exhaust. Added air conditioning, SSBC disc brakes. Rebuilt transmittion. pretty much anything you can do and a BUNCH of body work, functional not cosmetic.

- Joined

- Jul 2, 2010

- Messages

- 6,614

- Reaction score

- 121

- Location

- Warrenton, Virginia 20186

- My Car

- 73 Mustang Conv.

01 Mustang Bullitt (my son owns now)

04 Oxford White Mach 1

04 Azure Blue Mach 1 (sold)

Great job on the ram air parts. Very nice all around.

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

Very nice!

- Joined

- Jan 20, 2011

- Messages

- 2,191

- Reaction score

- 4

- Location

- Ancaster, Ontario

- My Car

- 73 Mustang Convertible

08 Bullet

WOW gets better all the time

Similar threads

- Replies

- 16

- Views

- 976

- Replies

- 30

- Views

- 2K

- Replies

- 16

- Views

- 812