Part 10 (Originally posted 27 Mar 2011)

Before we start let’s show more pictures of the engine with the headers on.

Since my last instalment there have been many changes with regards to the rebuild of the Trailer Queen and I have some good news, some not so good news and some bad news.

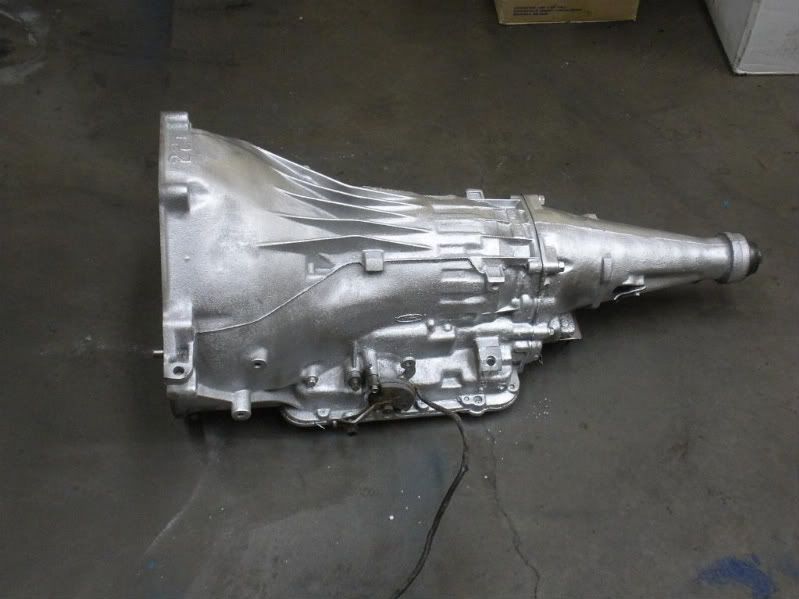

So, let’s start with the good news, we finally got some Dyno time at Armstrong Brothers in Kentville, NS. They were very helpful and quickly got the 351 mounted and prepped for breaking in and doing the Dyno pull. Once she was all set we crossed our fingers as the engine took its first breath after being torn apart and rebuilt. She started right up, but had to be shut down to adjust the timing, a couple of quick adjustments, a re-start and she ran flawlessly. About 10 minutes into the run oil and exhaust temps were checked, all normal. My wife was extremely happy at how easy the engine started, no more doing the 5 - 10 minute pre-departure “Dance” to get the car moving. The actual Dyno pull went just as easily, after three pulls the results were identical, max horsepower is 337 plus change, max torque is 387 ft/lbs plus change, not too shabby considering she’s not fully broken in yet, had the wrong headers at the time (the shop only had the 2V headers vice the engines 4V set-up) and was running a 650 Edelbrock carb / intake manifold, while not the best performance set-up, it does make for a very streetable cruiser. The only head scratcher is that the engine did not really want to rev above 5,000 rpm. I’m hard of hearing so I didn’t notice anything untoward, but the engine builder said it sounded like the valves were floating, I guess we’ll have to re-check the valve springs. Anyway, seeing how the wife is running a C6 transmission, the engine will probably never get to 5k and the wife is perfectly happy with the results. I have the Dyno sheet but it is very faint due to low ink in the printer, so we’re having someone manipulate the image to make it readable. We also took some video footage that my neighbour is editing for me. Once I get the proof in my hands I will immediately post it for all to view.

Ready to go on the Dyno.

The Dyno.

Engine secured to the Dyno. Those shop headers have the flanges for the smaller 2V exhaust ports.

Water hooked up and ready to go.

Now for the not so good news, the shop chosen to tear apart and re-assemble the Mach 1 had the car for a little over three weeks after receiving it from the body shop but had not done any of the work he was responsible for. This was due primarily to a lack of manpower and being way behind on many other projects, after a frank discussion it became apparent that he could not give us a firm start, let alone a completion date for the Trailer Queen. After further discussion it was reluctantly decided that we would look at other alternatives in getting the remaining work completed while compensating him for the work that he had done.

For the bad news, after the car was towed from the assembler we got our first good look at the assembled Mach 1 since it was dropped off at the body shop. The front end looked very much out of whack. The body shop did a superb job of replacing the rotten metal, repainting the engine bay as well as matching and blending the paint on the body, but we don’t know what happened to the front of the car. The shop did replace the front cross member and radiator support bulkhead, we think that it’s possible that the rad support may have been welded in either crooked or twisted. Either way we’re having the problem looked at by an independent body specialist to identify exactly what the problem is and discuss with us what our options are. Hopefully it will only require some tweaking and adjusting, but I seriously doubt it. My fear is that the rad support, and possibly the cross member may have to have the welds grounded off, pieces re-aligned re-welded.

Front end when the car was purchased summer of 2009.

Taken the day the car was loaded on flat bed to start its rebuild.

Just back from the body shop. It’s a little difficult to see but the grill is not sitting squarely in the opening and the bumper seems to sit a little higher than normal. When viewed from the side the grill appears twisted, the edges of the parking lamp bezels are not parallel (one side leans back while the other leans forward)

What are your comments on this?

End of Part 10. Part 11 to follow.