- Joined

- Apr 7, 2019

- Messages

- 286

- Reaction score

- 11

- Location

- NJ

- My Car

- 1990 Bronco, Eddie Bauer, 306ci

1978 F150 Ranger, 545 Stroker

1973 Mexican Mach 1 ( final confirmation TBD), 351C

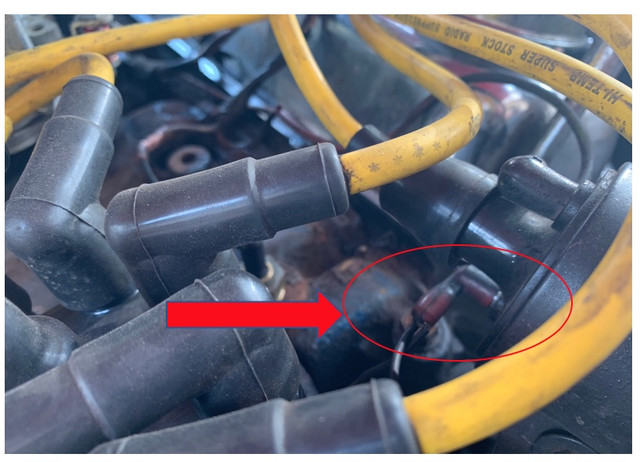

[url=https://ibb.co/kqFMPqf][img]https://i.ibb.co/GCjFrCL/pic1.jpg[/img][/url]

I am adding an aftermarket tach. the factory tach works fine, just hard to see.

I expected to find studs with a nut on the coil, but it uses right angled pressure fit caps. with a stud and nut, adding a tach wire would be easy. I'm not sure the best way to tap the neg wire with these pressure fit caps. any ideas?

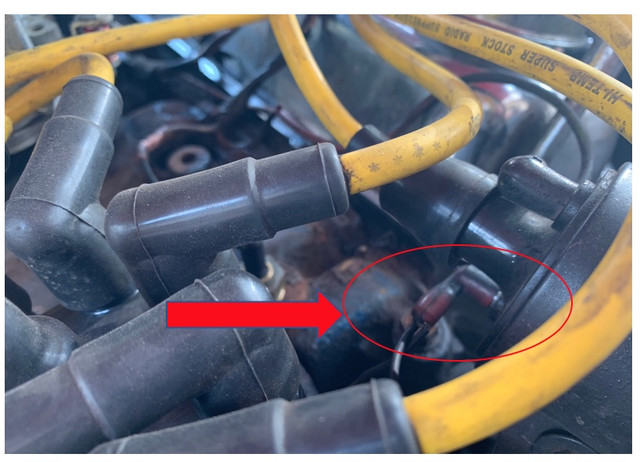

share images

I expected to find studs with a nut on the coil, but it uses right angled pressure fit caps. with a stud and nut, adding a tach wire would be easy. I'm not sure the best way to tap the neg wire with these pressure fit caps. any ideas?

share images