- Joined

- Jul 21, 2012

- Messages

- 3,240

- Reaction score

- 16

- Location

- South Florida

- My Car

- '71 Mustang Mach 1 M-code "Soylent Green"

'69 Plymouth Valiant 100

'68 Plymouth Satellite

IT LIVES!

More later...

-Kurt

More later...

-Kurt

Thanks, Q!Been following this build Kurt...Nice work ! I'm digging it ! ::thumb::

I was able to get a '72 302 (Mustang) air cleaner on top of it without issue either.I had to clearance a drop base open element air cleaner with a ball peen hammer to work with my Summit carb on my F-350. A stock 1970 390 air cleaner worked fine, as did the reproduction "HiPo" air cleaner for a 60's mustang.

Can relate on those 3TB storage units. Have one, 3TB WD just out of warrantee w/mfg and contracted through vendors's source w/ Best Buys which the driver went out on me w/2,72TB in pictures and movies via my Leicas. Will not let the Geek Squad 'crak it open via trashing it's casing however Western Digital now w/6TB storage and back up uitsare spose to be very reliable. the 6TB unit @$250.00 in outside storage fixture and for sure a 5TB back up block @same cost. which think should have had a back up block as the internet back ups to reset operating mode only.I've been intending to post a proper update with a video teaser, but got tripped up this weekend by a failed 3TB Seagate hard drive. Haven't lost any of the video, but I've maxed out a spare drive and have no drive pairs (one backup) over 500GB to allocate for the project video footage I've assembled over the last year. Wish I could afford a few drives to assemble a decent RAID array, and even a JBOD that would handle all my video files isn't THAT cheap when you're practically flinging money at the car.

In the meantime, you'll all have to be content with a few engine photos from Sunday. Front of the intake is a MESS from the thermostat outlet leaking (t-stat wasn't centered at first install, cue a big geyser of water during the pressure test), and was compounded by the bypass nipple leaking (ditched the Teflon, gave it a good fat coating of sticky gasket shellac and shoved it back in there - I don't care how much of a pain it'll be if I ever have to get it out again, so long as it doesn't leak).

-Kurt

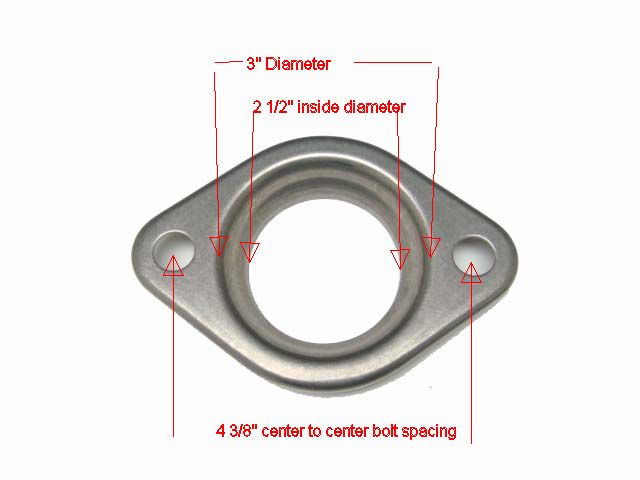

OEM-replacement spec Walker turbo mufflers with 2.5" glasspacks behind it.What mufflers are you running?

Enter your email address to join: