Is it me or are these Clevelands very hot running engines? Not boiling over/ obvious problem type hot, just damn hot in general. Assuming I'm not alone, what have you guys done to help lower the temps under-hood?

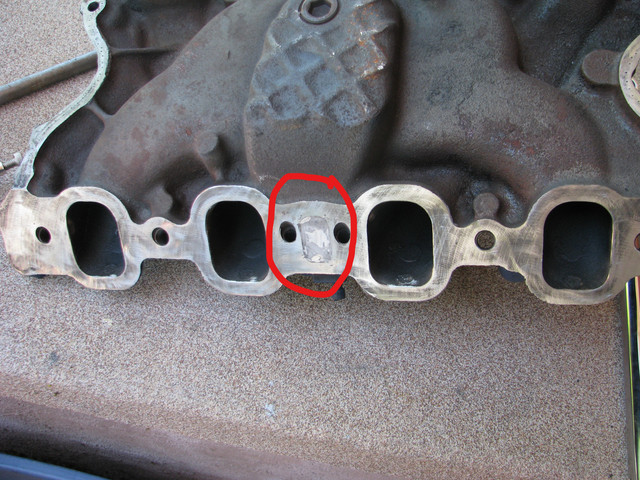

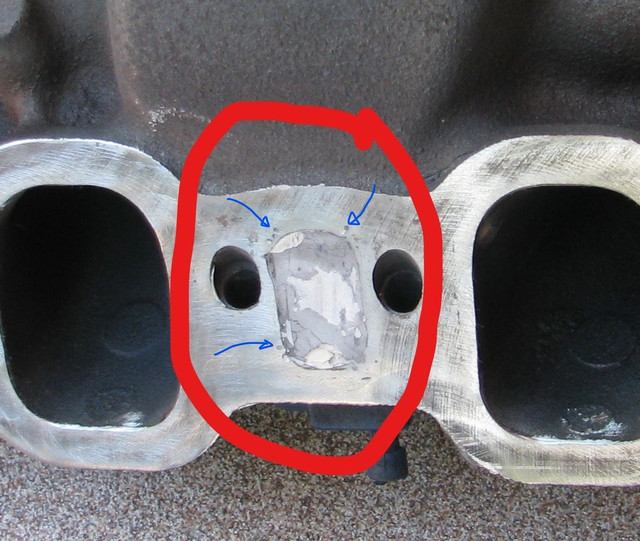

I definitely wish I had blocked off the exhaust into the intake. I feel like that was a huge mistake that I made when I had the intake off and was re-sealing it. I will definitely block it off when I swap this intake for a Blue Thunder. Even with a 1/4" spacer, the carb gets extremely hot.

I have Hooker long tubes. I wish the previous owner had opted for ceramic coated, but he didn't. I may end up purchasing a set of those. They say 30% lower temps with those. Would you all agree?

Even though I don't boil over, I'm not confident in the current cooling system. My gauge always reads low regardless. I don't trust it at all. My fan clutch is constantly engaged because the radiator gets pretty hot almost immediately after start-up. I'm thinking about buying a Champion aluminum radiator. I have a new T-Stat and bypass plate coming from T-Meyer.

My current thought is that this old radiator is partially restricted, or I don't have the bypass plate installed. Neither would surprise me.

The heat transfer is insane. Even my strut tower braces get hot enough within minutes that you definitely don't want to touch them. I'm assuming that's from the header heat coming straight up.

Anything else you guys can suggest while I build my shopping list?

I definitely wish I had blocked off the exhaust into the intake. I feel like that was a huge mistake that I made when I had the intake off and was re-sealing it. I will definitely block it off when I swap this intake for a Blue Thunder. Even with a 1/4" spacer, the carb gets extremely hot.

I have Hooker long tubes. I wish the previous owner had opted for ceramic coated, but he didn't. I may end up purchasing a set of those. They say 30% lower temps with those. Would you all agree?

Even though I don't boil over, I'm not confident in the current cooling system. My gauge always reads low regardless. I don't trust it at all. My fan clutch is constantly engaged because the radiator gets pretty hot almost immediately after start-up. I'm thinking about buying a Champion aluminum radiator. I have a new T-Stat and bypass plate coming from T-Meyer.

My current thought is that this old radiator is partially restricted, or I don't have the bypass plate installed. Neither would surprise me.

The heat transfer is insane. Even my strut tower braces get hot enough within minutes that you definitely don't want to touch them. I'm assuming that's from the header heat coming straight up.

Anything else you guys can suggest while I build my shopping list?