- Joined

- Mar 30, 2017

- Messages

- 2,393

- Reaction score

- 884

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

[... thinking it would be a simple swap...]

Well, it is!

Made a quick and dirty drawing for you if you would start from scratch with new metal, would let the parts be folded/cut for you at your local truck builder/ metal work place etc...

Ingredients you need: a few onces of patience, a piece of cardboard, a thin sheet of aluminum, and ideally the chrome bumper + bracket/plate

After you remove the 73 bumper+brackets, place the 72 bumper with some construction, so it would be as you wish on the car.

use the cardboard to make one or a series of small shapes, with all measurements...

Transfer all these shapes/measurements to a thin sheet of aluminum. Using 1mm thickness, you can then fold by hand

and test on the car. (slightly thicker, like 2mm would even allow you actually mount the bumper, but would be harder to fold).

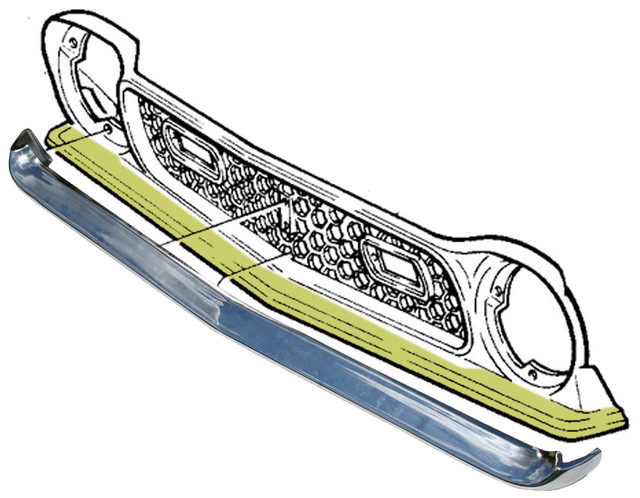

you should end up with something like this, when flat. (totally not in ratio, but shows how fairly simple the shape is)

Your could use wood too for this. I personally prefer alu, so I don't have to screw anything for the 90 deg cases

and also because thickness is near of the final thickness, leaving no to little marging for errors when I make a blank test assembly.

(where fat black is where you need fold, at yellow dot, is what I would add that is not on the 712 brackets (so you could cover the empty space between grille and bumper with a simple single folded plate). in green, where additional welds once folded would be welcome to add strength to the piece (bridge to fold side to part body)

Once you have this shape, if you don't have the tools to do it, you can let it done at your local metal/truck builder shop.

Here a at my fav local shop, a press fold 90 deg, costs $3 per fold/press cut, the industrial metal plate in 3 or 4 mm for both sides 40 to 90 depending on steel quality. If your shape is well defined, you'd add a couple of hours work to the bill.

If you have tools, you can also go for shortening the bracket you can weld that to the 73 square tubes. Or just relocate the holes of the original 712, cut the metal that prevents to have a flat contact onto the car frame...

@rocket366 did probably one of these like I did. If I would redo today,as I do not have the original 73 tubes anymore, I'd go for new metal with the additional bracket for the missing plate.

In short, all depends if you have tools or not, and say: today, I do the swap.

and then when done, you will look at projects like @wide-body71's and think... wow respect

Well, it is!

Made a quick and dirty drawing for you if you would start from scratch with new metal, would let the parts be folded/cut for you at your local truck builder/ metal work place etc...

Ingredients you need: a few onces of patience, a piece of cardboard, a thin sheet of aluminum, and ideally the chrome bumper + bracket/plate

After you remove the 73 bumper+brackets, place the 72 bumper with some construction, so it would be as you wish on the car.

use the cardboard to make one or a series of small shapes, with all measurements...

Transfer all these shapes/measurements to a thin sheet of aluminum. Using 1mm thickness, you can then fold by hand

and test on the car. (slightly thicker, like 2mm would even allow you actually mount the bumper, but would be harder to fold).

you should end up with something like this, when flat. (totally not in ratio, but shows how fairly simple the shape is)

Your could use wood too for this. I personally prefer alu, so I don't have to screw anything for the 90 deg cases

and also because thickness is near of the final thickness, leaving no to little marging for errors when I make a blank test assembly.

(where fat black is where you need fold, at yellow dot, is what I would add that is not on the 712 brackets (so you could cover the empty space between grille and bumper with a simple single folded plate). in green, where additional welds once folded would be welcome to add strength to the piece (bridge to fold side to part body)

Once you have this shape, if you don't have the tools to do it, you can let it done at your local metal/truck builder shop.

Here a at my fav local shop, a press fold 90 deg, costs $3 per fold/press cut, the industrial metal plate in 3 or 4 mm for both sides 40 to 90 depending on steel quality. If your shape is well defined, you'd add a couple of hours work to the bill.

If you have tools, you can also go for shortening the bracket you can weld that to the 73 square tubes. Or just relocate the holes of the original 712, cut the metal that prevents to have a flat contact onto the car frame...

@rocket366 did probably one of these like I did. If I would redo today,as I do not have the original 73 tubes anymore, I'd go for new metal with the additional bracket for the missing plate.

In short, all depends if you have tools or not, and say: today, I do the swap.

and then when done, you will look at projects like @wide-body71's and think... wow respect