- Joined

- Sep 12, 2015

- Messages

- 7,995

- Reaction score

- 3,104

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

Backstory;

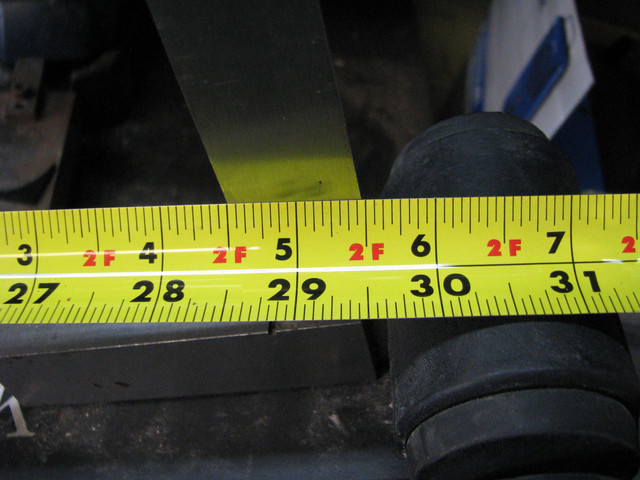

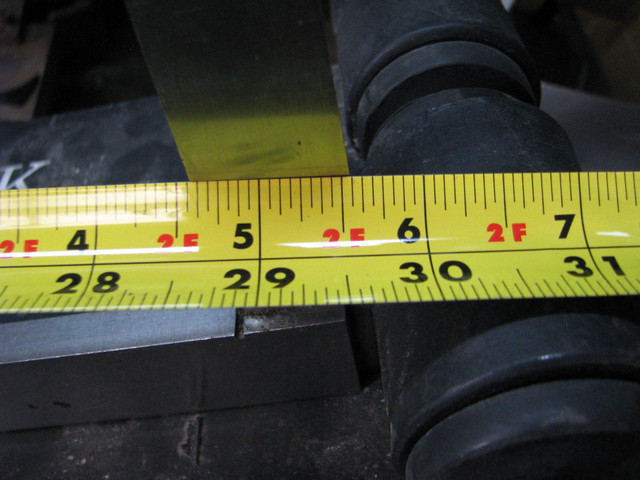

A couple of years ago, I decided it was time to replace the rear springs on my 71 351C 4V, 4 speed Mach 1. This car has an open 3.25:1 dif and spring wrap-up was an issue with the old worn out springs. I chose Grab-A-Track 4 1/2 leaf standard eye. Not sure what the load rate is, but the spring rate is 175lbs. I also added a 7/8" anti-sway bar, replacing the minimal 1/2" factory thing. The result was the back end sat up way too high and needed 1" lowering blocks to get it close to where I think it should be. My thought was the springs would settle to where the blocks could be removed, but I was wrong. The old springs had a free arc of 5" (measured from center of the eyes to the top spring at the pins). The 4 1/2 leaf measured 7", so with load, weight of the car, they were still 1" too high. I realize the old spring would likely have lost some arc over time, but I don't want the ass end up that high with 14" wheels, looks stupid!

Moving forward, I just removed the rear axle for an overhaul, so my plan is to buy another set of springs. Referring to the NPD catalog (they're cheaper than buying direct from Eaton Springs) the base spring rate is 138 lbs for my car. The Boss lists 152 lbs. The 429 lists 138 also, but there are optional 1" lowering springs available. The listing for both 351C 4V and 429 with comp are the same part #, at 138 lbs. The optional rate is 153 lbs from 10/9/70, but only 1" lowering. I would go with the 153 lbs lowering springs IF I knew the free arc was around 6" or less, which I've been unable to establish to this point. The other choice of course is to get Boss rated standard springs at 152 lbs.

The GAT's at 175lbs are really not that harsh and with the bigger ant-sway bar, cornering is pretty good, which of course, I like. My aim is for a stock look. I'm not into the overly modified style.

So my friends, what would you do? What would you chose?

What I can do is go to NPD in Canton Mi and see for myself and compare the different springs (assuming they're in stock). I would have to go and pick them up regardless as shipping would be outrageous into Canada.

Thanks in advance,

Geoff.

A couple of years ago, I decided it was time to replace the rear springs on my 71 351C 4V, 4 speed Mach 1. This car has an open 3.25:1 dif and spring wrap-up was an issue with the old worn out springs. I chose Grab-A-Track 4 1/2 leaf standard eye. Not sure what the load rate is, but the spring rate is 175lbs. I also added a 7/8" anti-sway bar, replacing the minimal 1/2" factory thing. The result was the back end sat up way too high and needed 1" lowering blocks to get it close to where I think it should be. My thought was the springs would settle to where the blocks could be removed, but I was wrong. The old springs had a free arc of 5" (measured from center of the eyes to the top spring at the pins). The 4 1/2 leaf measured 7", so with load, weight of the car, they were still 1" too high. I realize the old spring would likely have lost some arc over time, but I don't want the ass end up that high with 14" wheels, looks stupid!

Moving forward, I just removed the rear axle for an overhaul, so my plan is to buy another set of springs. Referring to the NPD catalog (they're cheaper than buying direct from Eaton Springs) the base spring rate is 138 lbs for my car. The Boss lists 152 lbs. The 429 lists 138 also, but there are optional 1" lowering springs available. The listing for both 351C 4V and 429 with comp are the same part #, at 138 lbs. The optional rate is 153 lbs from 10/9/70, but only 1" lowering. I would go with the 153 lbs lowering springs IF I knew the free arc was around 6" or less, which I've been unable to establish to this point. The other choice of course is to get Boss rated standard springs at 152 lbs.

The GAT's at 175lbs are really not that harsh and with the bigger ant-sway bar, cornering is pretty good, which of course, I like. My aim is for a stock look. I'm not into the overly modified style.

So my friends, what would you do? What would you chose?

What I can do is go to NPD in Canton Mi and see for myself and compare the different springs (assuming they're in stock). I would have to go and pick them up regardless as shipping would be outrageous into Canada.

Thanks in advance,

Geoff.