So many people build an engine with a new and aggressive cam' date=' new intake and carb, raise the compression, add headers, and other mods and then claim the HP gain is from the port and chamber work they did on the heads - LOL.[/quote']

My comments were based on head porting alone, LOL

Do any of you own a extrusion porting machine?

If you are referring to a "putty porting/Extrude Hone machine, those have been around for ages and we had some cylinders on the factory Works MX bikes done using this process when I was a project engineer and ran part of the R and D department for Kawasaki Motors Corporation.

Do you have a wet flow bench

No, but if I did I would dry it off, besides, I don't need ant flow bench because my friends Bob Mckray and Mike Hayden both have access to one and Mike is listed 44th all time fastest in NHRA history in his class driving his own car with an engine he built and also has his own drag strip in his back yard so he can do testing . . Do ya got one of those?

http://www.draglist.com/lists/pstq32.txt

How many 1500hp at the flywheel small block engines have you built?

Not a single one, however that is irrelevant because it has absolutely nothing to do with the FACT that properly porting a 4V Cleveland head will increase an engines horsepower.

I still have one hanging on a stand in my shop.

If it were me, I would fix whatever you did wrong that is preventing it from being used and get it out of the garage.

.

OMIE

As far as the balancer goes its not a matter of taking the bolt out and removing it, its that this short block rotating assembly was balanced with it.

You can remove the balancer then take both it and the new balancer to any balance shop and have it matched balanced . . I have had parts matched balanced many times . . Might cost around $100.00.

I do have an STI approved balancer' date=' but was wondering if I can just swap them out without re-balancing the rotating assembly.[/quote']

More than likely because in my experience, material s rarely removed from a balancer during balancing, but it would be safer to have the balance checked on both first as i mentioned above.

And yes' date=' the heads may flow better if reworked, but my point is that a 4v head can make 350-375hp without the work, and in true "Boss" trim they wouldn't be.[/quote']

Yes they can but you missed my point, so just leave them the way they are, but as I mentioned, it will be a little harder and get the power that way, which means you will have to use a cam that is a little bigger than you otherwise would to do it, but since your hp goals are fairly moderate, you will really be ok just leaving them.

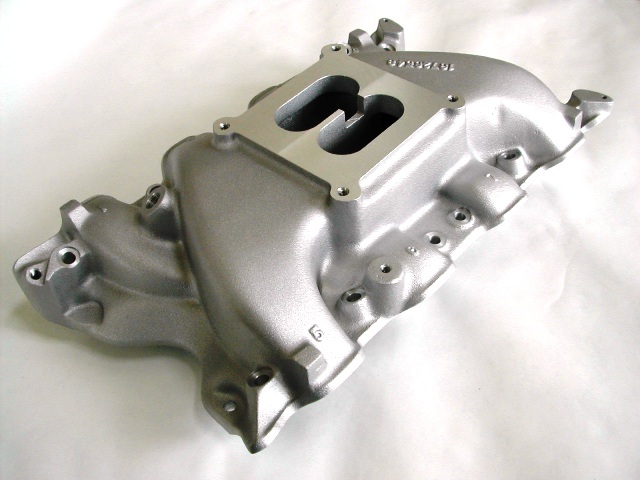

As far as intakes, they are easy to change, so if my performer won't do it, some day down the road I "could" change it. I would really like a true "Boss" intake but right now its not in the budget. Please understand, I'm not looking to maximize HP, I'm looking to build a good "Boss" clone engine for my "Boss" clone car.:whistling:

I can not impress upon you just how much you are defeating your purpose by using that pathetically wimpy intake on there, and the Blue Thunder is more similar to a real Boss intake than that one is, but at least you now have the info for future reference if needed . . I just really hate to see you leave all that additional power on the table, that's all.

Cylinder heads –

Paul of MO is right with his response. I have seen and read many articles on where engine builders have milled 4V cylinder exhaust head ports to add redirected and smaller port size to increase efficiency.

He's right because you read it on the internet so it must be true?

Did you somehow miss all the posts stating that porting 4V Cleveland heads increases power?

.