- Joined

- Feb 20, 2020

- Messages

- 1,094

- Reaction score

- 342

- Location

- North Georgia

- My Car

- 1972 Mach 1 dark green

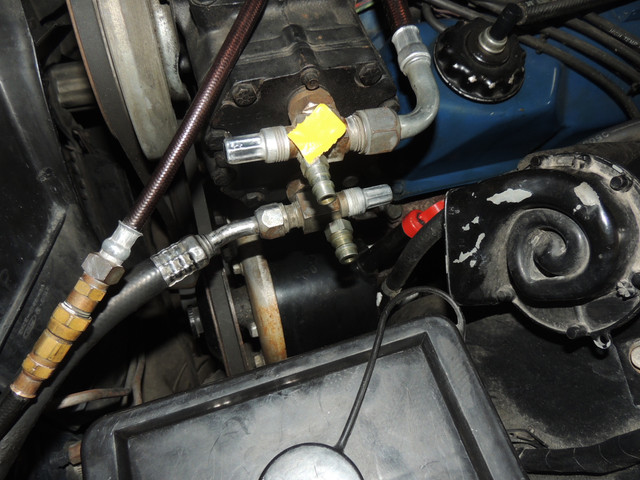

Dropped off my car at an A/C shop today to find out if the compressor and related parts are good or not, it has the original York in it. Also need to know if it had ever been converted from r12 to 134. I told the shop that if the compressor is bad to disconnect the lines and I will pull it out, that will give me more room to work on the engine bay, clean, paint, etc. Then when the time comes I can install a new compressor and have them do the lines, charge or whatever else it needs. So if it does need to be replaced I will have to decide between an original style, York or go with a Sanden, either way I want r134a as I think it would be easier to maintain down the road. thoughts?? I have read other posts but still want to ask.

Thanks

Thanks