Gentlemen, I thank you for the kind words. Sometimes I wonder if I could make it through this job without your support - though I'm very glad that it is not the case.

Anyway, I feel I owe it to the forum to show a few of the problem areas.

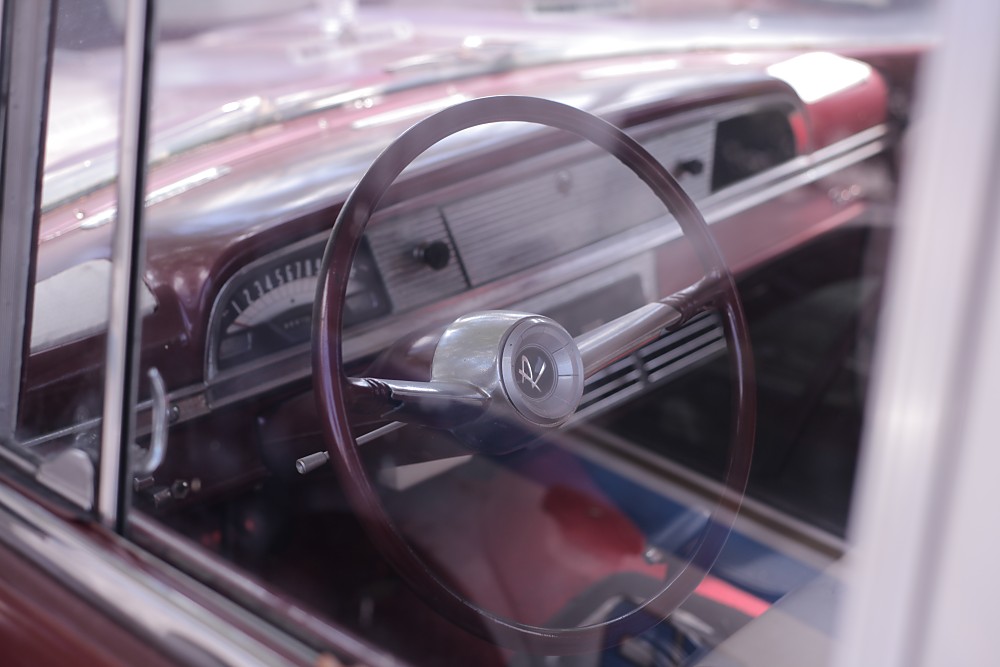

After slicing a slit in the badly-repaired trunk (and pulling the outer skin back to its factory position), I was met with this. I have fit the end cap to where it SHOULD be, rather than trying to match it up to the fender:

Besides not fitting correctly on top, the entire end cap is binding on the lip of the taillight lens bulge on the taillight panel, causing the lower half to push outwards; especially on the inside.

Now if we go back in time - picturewise - here is a photo of the panel end as found (with the dealer replacement Ford-service taillight panel) - note how much lower it sits than the filler/rubber channel to its left...

...and here is the same panel, tacked (at the filler) with the replacement taillight panel:

Now, there is the argument that I put the taillight panel in too high on the right side - but the panel automatically aligned itself via the weatherstripping channel. Lowering the panel on that side would have required removing and lowering the filler piece to match.

Hence, it is my belief that:

A. The quarter panel was installed wonky from the factory to begin with

B. The dealer-replaced taillight panel (the one I cut up) was installed low (how, I don't know - perhaps the repop panel has different tolerances) to compensate for the fit issue.

C. The original taillight panel was probably installed low on that side too.

Come to think of it - I may be able to solve most of my problems by dropping the new taillight panel down on the right side, and installing the replacement patch to fit - and getting a patch that has the filler panel already connected to it. My best bet, most likely...

-Kurt