BDK

Well-known member

Will the Fitech fit under the RAM-Air cleaner and RAM-Air plenum??All,

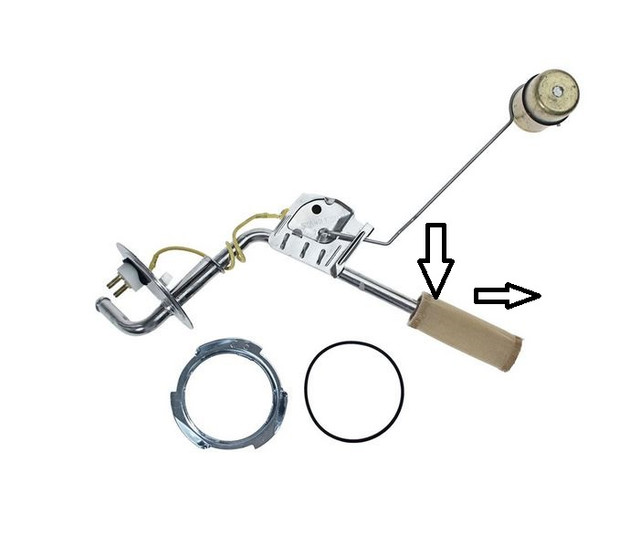

Started working on the Tanks Inc. PA-4 fuel pump install in my new Tanks Inc. fuel tank. Several items of interest while installing. I got the tools mentioned by AutoEdit’s video, the 3 and 4 inch hole saws. We used the 3 inch one first to cut a 3 inch alignment plate to install into the evaporate opening. We noticed a bit of movement of the plate, when trying to lock it down. We had to align the hole, we locked it down with the ring. Cut the 4 inch hole. Next, we laid the mounting ring to trace the mounting holes. I noticed that the cut out opening was not as big as the I.D. of the mounting ring. OK, well, then. So, I drilled the holes to the size per the instructions. Slipped the ring inside and inserted the screws. Here is where I again noticed the cut out hole was little smaller that the I.D. of the mounting bracket. Well, the lip over hang to the mounting ring was further in than what I saw on the video.

Our fix to this little issue was to use a spot weld cutter in 4 corners of the ring circumference area. Since the tanks metal thickness is thin, it did not take much cutting to open up a weld hole. We tacked 4 holes, ground it smooth. When it was time to insert the fuel pump bracket, we had a bit of clearance problems. We rectified that issue with rounding out the edges of the main bracket to the sump tray. Slid right in.

After all is said and done, I went back to the instructions and found that it says “ Tack weld the ring on the inside of the 4 ½ inch opening. “ Wait a minute, According to AutoEdit’s video, he used a 4 inch hole saw.

My suggestion on this project, would be to look at a 4 1/8 hole saw. I believe the 4 ½ may not provide much material around the mounting holes. On the evaporate hole plate, I would look at the 3 1/8 hole saw. I would recommend to measure sure to make sure, though.

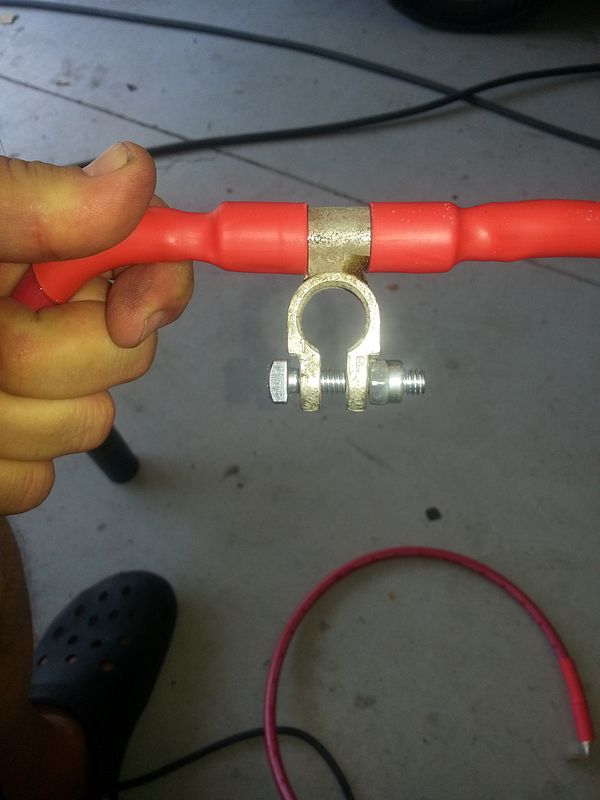

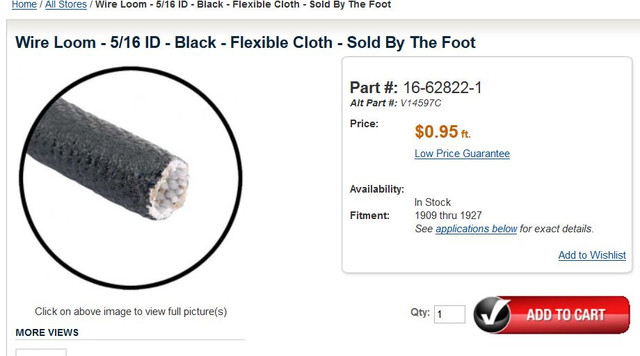

Next, the hardware that comes with the kit is all zinc plated. IMO, zinc plated hardware does not stand up to the weather very well. I am looking into #10 stainless steel hardware for all mounting points.

Keep you posted.

Mustang7173

BDK