- Joined

- Sep 12, 2015

- Messages

- 8,124

- Reaction score

- 3,209

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

Finally an update, gauges not yet installed, but an update.

I bought the Bosch gauges and made a bracket rather than messing up the factory set. I decided to just paint the entire center panel with SEM Trim Black. Actually, it looks quite good and as I don't have the chrome accents on the other gauges, it won't look out of place.

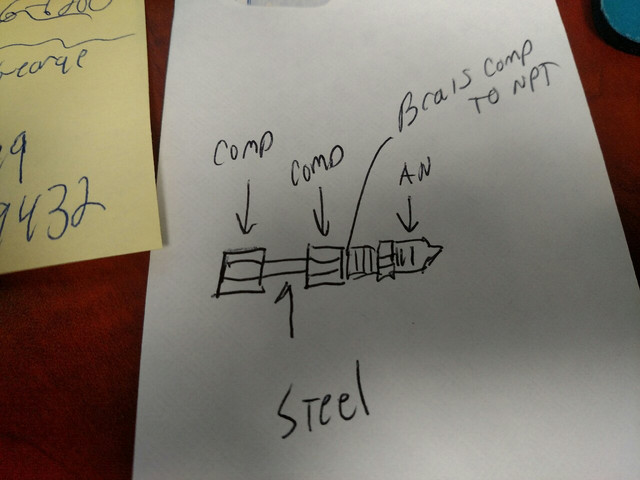

Now for the issue of the oil gauge supply tube. I would like to avoid using the plastic tube that was supplied for the basic reason they can and do break. Copper is an option, but copper can work harden with engine movement and vibration and also break. The best solution is braided stainless steel with A N fittings. Problem is they only have NPT adaptors while the Bosch gauge has a straight 5/16-24 thread for the feral nut. Sooooo, my question is this, has anybody found a suitable adaptor to go from the 5/16 - 24 thread to the 4 A N fitting? Jegs have this ss tube on the website, 36" for $24.95 US. Auto meter have it, same thing, for 53 bucks.

I'd be very interested if there is a solution out there. Bosch have nothing to offer, just the plastic tubing.

I'm putting up a few pics of where I'm at with this "project" . #1 gauges from the back. #2 front, but way before refinishing (no picture yet), #3 the bracket I fabricated.

Geoff.

I bought the Bosch gauges and made a bracket rather than messing up the factory set. I decided to just paint the entire center panel with SEM Trim Black. Actually, it looks quite good and as I don't have the chrome accents on the other gauges, it won't look out of place.

Now for the issue of the oil gauge supply tube. I would like to avoid using the plastic tube that was supplied for the basic reason they can and do break. Copper is an option, but copper can work harden with engine movement and vibration and also break. The best solution is braided stainless steel with A N fittings. Problem is they only have NPT adaptors while the Bosch gauge has a straight 5/16-24 thread for the feral nut. Sooooo, my question is this, has anybody found a suitable adaptor to go from the 5/16 - 24 thread to the 4 A N fitting? Jegs have this ss tube on the website, 36" for $24.95 US. Auto meter have it, same thing, for 53 bucks.

I'd be very interested if there is a solution out there. Bosch have nothing to offer, just the plastic tubing.

I'm putting up a few pics of where I'm at with this "project" . #1 gauges from the back. #2 front, but way before refinishing (no picture yet), #3 the bracket I fabricated.

Geoff.