- Joined

- Aug 8, 2018

- Messages

- 414

- Reaction score

- 217

- Location

- California

- My Car

- 72 Sportsroof - 351C-4V, Fitech EFI, T56 Magnum 6 Speed

Unfortunately I have no idea what's inside this thing. I only learned yesterday that it had rollers. I basically got the car with no history other than a couple people who knew of the car, but no details.

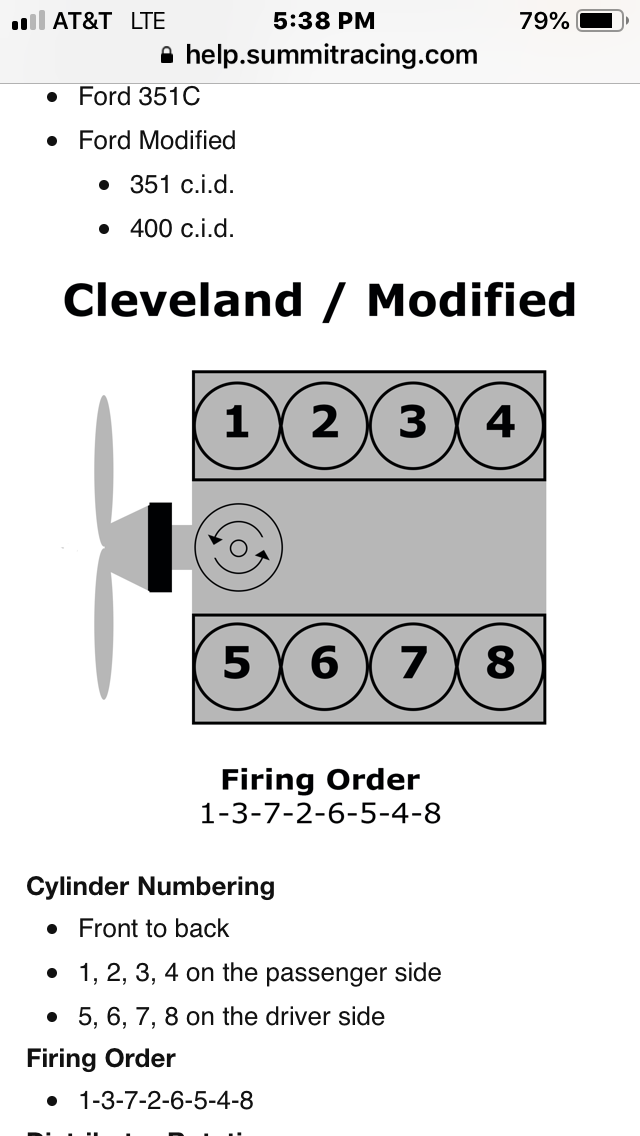

All the other cylinders are running at temp. Checked the firing order several times, but I'll triple check as I've love that to be the issue.

All the other cylinders are running at temp. Checked the firing order several times, but I'll triple check as I've love that to be the issue.