- Joined

- Aug 8, 2018

- Messages

- 414

- Reaction score

- 217

- Location

- California

- My Car

- 72 Sportsroof - 351C-4V, Fitech EFI, T56 Magnum 6 Speed

Just realized that those last pics I posted probably weren't showing up. Should be working now.

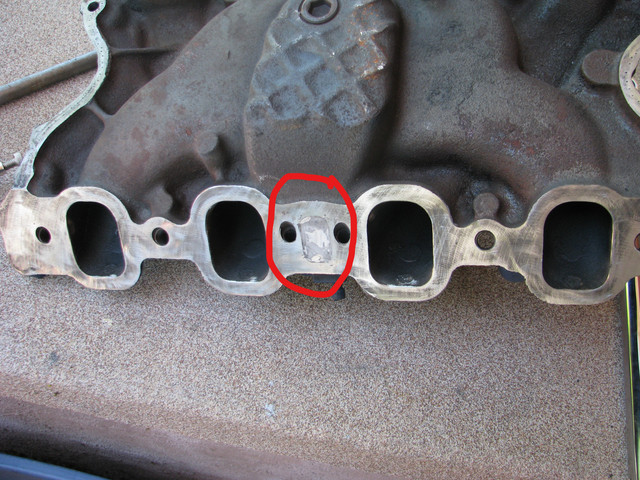

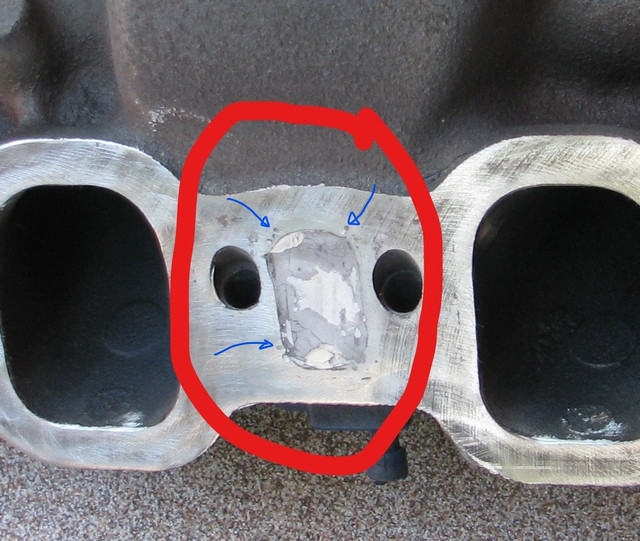

Yes, I did. It was on a Boss 302 but, same problem, sorry azz print-o-leak fel-pro gaskets. Use anything else. ChuckThat's definitely a big enough leak to cause enough oil to quickly foul the plug, as well a making it too lean to fire before it starts sucking in oil.

With that much of the gasket missing I would want to make sure it isn't stuck in one of the valves.

I think Chuck (c9zx) also had this kind of failure.

Had a few minutes to try and get a measurement or two. This is just ballpark as I was doing this myself in the dark and really couldn't get a good angle. But a quick check of both intake and exhaust lifters are about .340. Again I need to check this again when I get some help and some better light, but that's what I'm seeing at the moment. Is that good, bad, other?Does your calipers have a depth measurement rod? If not, you won't be able to use them. If so, slowly turn the crankshaft by hand while pushing down on the lifter, until the lifter is at it's lowest point. Measure from a point on the lifter guide to the top of the lifter, and mark that point. Turn the crankshaft until the lifter is at it's highest point. Measure from the same point on the lifter guide to the top of the lifter. Calculate the difference between the lobe peak and base.

Dude, I don't really think I'd trust a thin piece of aluminum to stand up to constant heating. Even at 1200 f melt point, under the intense focused heat I don't think I want to risk pulling the intake to do again. Just my thought on it. I wasn't even sure that .020" piece of SS would last long.OK cool, I didn't think it was needed and seemed like it could hurt performance once up to temp. I'm running an Edelbrock Performer 1407. Aluminum melts at around 1,200°F. The exhaust gas is hot, but surely not that hot? I was thinking a small piece behind the gasket on the head side. That said, I do like the idea of dealing with this at the intake like you did.

Thanks

Back in 2016 when my motor had to be rebuilt again, I had a major leak there too. The engine builder put the rubber end seals in against my request not to, so I assumed that was the cause of the leak. I pulled the intake and reassembled it using a good 1/4" + bead of "The Right Stuff". Tip here, make sure you extend the bead up about a 1/2" from the corners where the heads meet the block. The corners are where it's likely to leak. Guess what, it leaked again. In my frustration, I called the engine shop and the builder said "Oh, I may have forgotten to tighten up the plug on the oil sensor "T" adaptor" . That was the cause of my leak!!I didn't see the oil coming out, but assumed it's the manifold seal as I didn't touch the sensor and that whole area was full of oil. I'll confirm before ripping things apart.

Enter your email address to join: