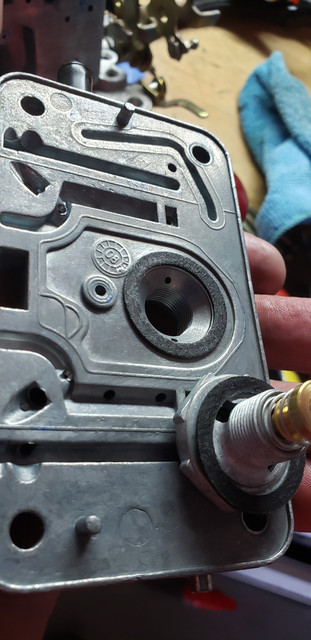

I don't think I have a choice but turn my attention back at the carb. This Street Avenger 770 that so many seem to loathe. Stanglover, I definitely need more info on those 3/32 holes your speed shop guy drilled in your butterflies that cured you of the same issue. : ) I'm also definitely taking the power valve back down From the 8.5 at this point. I also need to confirm the original jet sizes and squinter that came with this carb. I think those were swapped also.

In the meantime, I'm also going carb shopping on the web. ;-)

Hi Big Red, Not that it matters, earlier I thought you said you had a S/A 670, now you mention S/A 770.

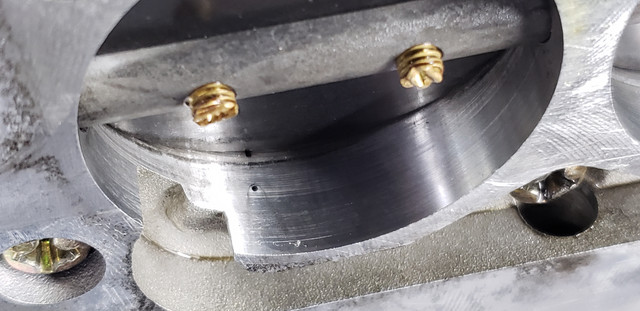

As I have said many many times, I'm no expert on carbs, but in my case with the Holley S/A 670 I have that was over rich at idle, the speed shop carb tuner guy, went straight to drilling the 3/32" hole in each primary plate AFTER test driving the car and letting it settle into a steady idle, the gas smell was horrendous . He removed the carb and saw right away that I had the transfer slots way to far open, just to keep the motor idling. The idle screws were the usual 1 1/2 out. Now, is this guy a super expert? I don't know, but he knows more than do I and he does it for a living. Also, you mentioned opening the secondary's for more air, that I had done also, so he reset them correctly too. The 3/32' dia. was a start point, but it worked in my case, so I never enlarged them. These hole are drilled pretty much in the center of the forward part of the plate i.e. forward of the shaft.

This notion has caused much discussion, mostly negative, but trust me it worked. I have very little gas smell around the car or in the garage, which in the past was enough to choke a horse (mustang?) I'm NOT saying go head and do this, but it might be worth a try especially if you're thinking about a different carb anyway. If you do remove the plates, make sure you loc-tite them or peen the screws so they never come lose, but you're a mechanic, you know that anyway.

It was not just about loosing the gas smell and over rich idle, but about getting my motor to run better than it ever did in the past. To recap, my motor is pretty much stock with just a small increase in cam lift. I did borrow an AFR meter, I already had O2 bungs in the exhaust from an earlier run on a dyno, so running the AFR was simple. (I have a video of that I may post if I can find it and think it relative).

You may also have looked at my post on Edelbrock carbs and a bunch of amusing videos, yeah well, I'm not convinced on that brand for MY car. For me if I ever decide to replace my 670, I lean toward the Quick Fuel HR 735, or possibly the Summit series in that cfm range. I just fell the 670 does not provide quite enough air at wot.

Hope that dose not confuse the issue even more.

EDTIT: before anyone jumps on " the holes will have no effect once the throttle plates open past idle" that was not what I meant. but Just part of setting the entire carb up for better performance. The curb idle could not be correctly set until other changes were made. It all goes hand in hand.